MAINTENANCE

Maintenance Section 5-8

© 2005 Alamo Group Inc.

GRIZZLY 66 01/05

Removal

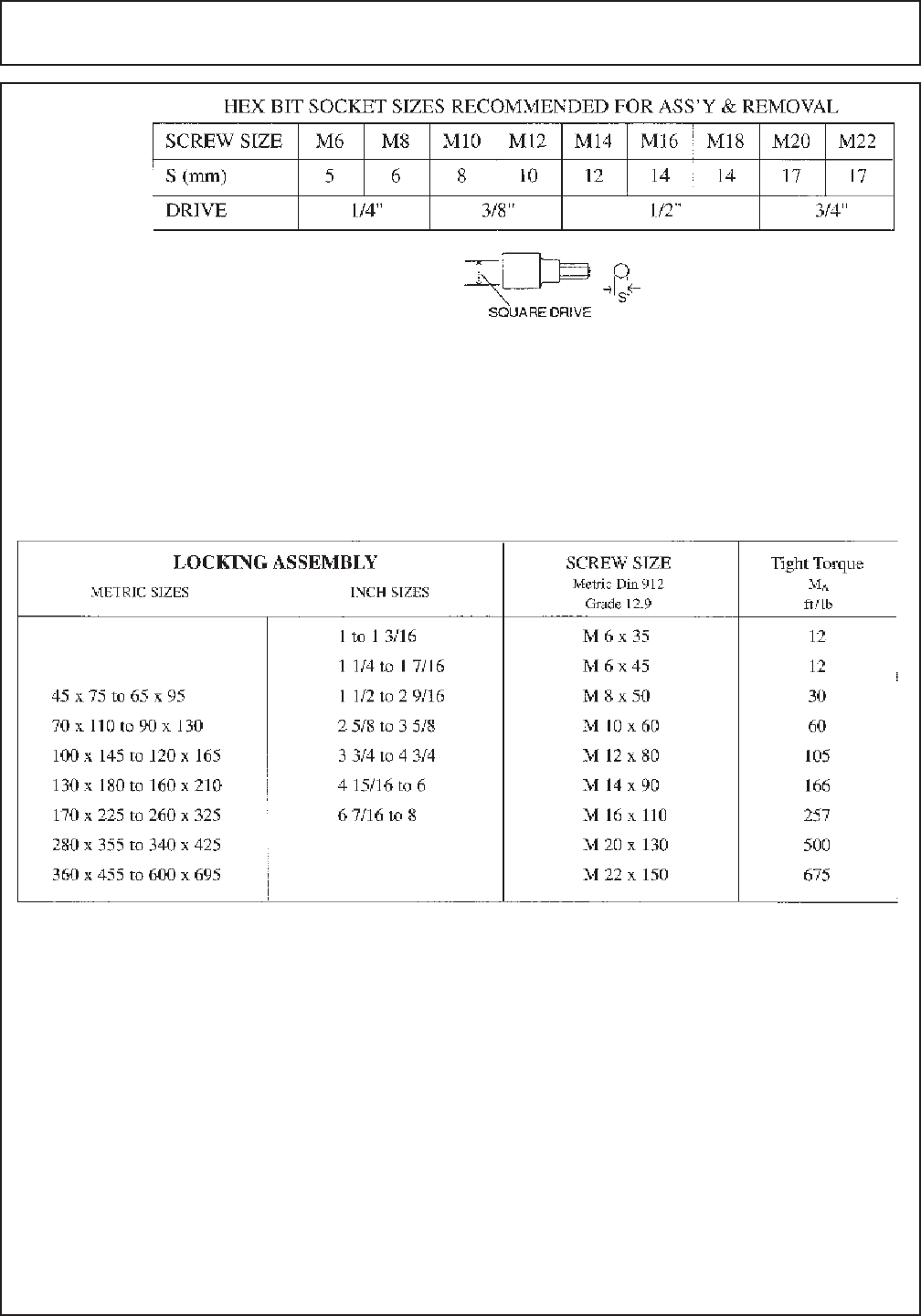

1. Make sure axial movement of clamp collars - necessary for release of connection - is not resricted.

2. Relax all locking screws by at least 2 turns and transfer locking screws into all push-off threads

provided in clamp collar item "1" and center collar item "3" as illustrated in Figure 2.

3. Release connection by progressively tightening all push-off screws in diametrically sequence except

for screws adjacent to slit in clamp collar item "1", which should be tightened one after the other.

(TABLE 4)

(TABLE 5)

1. The brushcutter requires a constant flow of hydraulic oil that will not be reduced when another machine

function is used simultaneously.

2. Use a "Motor spool" type of control valve. If not possible, a system of recirculating check valves must be

used. Circulating system and crossover relief for drive motor protection are provided with the cutter.

3. Line Sizes: All pressure lines are to be minimum 1" diameter. All return lines, 1 1/4" tubing (except when

dual rotation is used-both lines must be high pressure. Flows below 30 GPM may use smaller line sizes).

Confirm line size with each application.

High pressure machines use a motor capable of operating at 3500 p.s.i. with a correspondingly lower flow

rate.

4. The shaft speed must not - UNDER ANY CIRCUMSTANCES - exceed 1800 RPM.

5. Secure all wear parts as per factory original installation. (Follwing servicing, sharpening, etc.)

General Instructions