MAINTENANCE

Maintenance Section 5-7

© 2005 Alamo Group Inc.

GRIZZLY 66 01/05

The frictional torque capacity of these devices is based on lightly oiled screw, taper, or shaft and bore contact

areas with a coefficient of friction µ = 0.12.

Therefore, it is important not to use Molybdenum Disulfide, e.g., Molykote, Never-Seeze or similar lubricants

in any locking assembly installation.

1. Make sure shaft and bore contact areas are clean and lightly oiled.

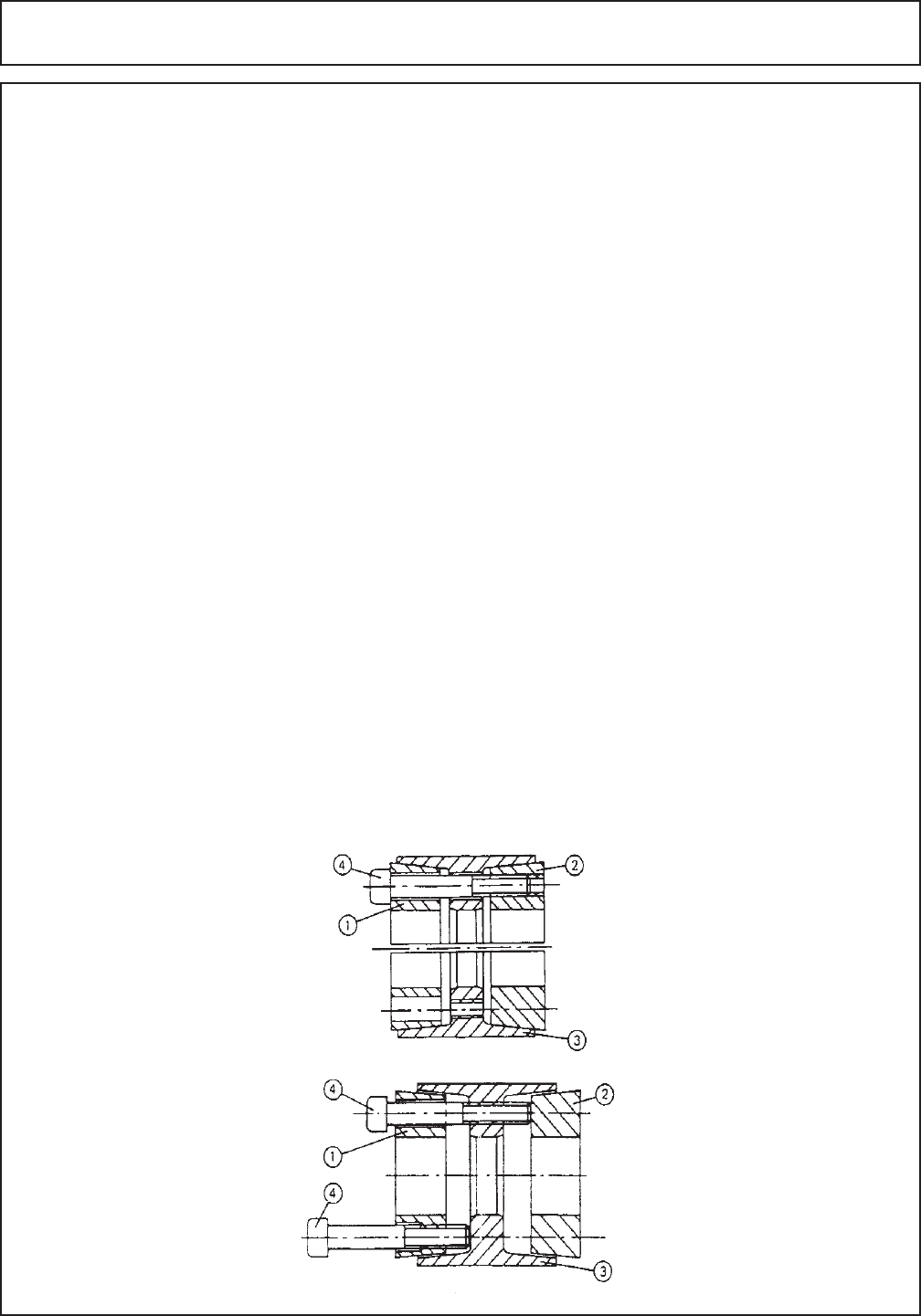

2. Loosen all locking screws by a minimum of 2 turns and transfer at least 3 screws each to equally

spaced push-off threads in clamp collar item "1" and center collar item "3" in order to disengage

tapers for easy installation of locking assembly. See Figure 1.

3. After installation of locking assembly, relocate locking screws used for separation of collars.

4. Tighten locking screws evenly in several stages to tightening torques M

A

as specified on assembly

drawing or, as shown in Table 6, a diametrically tightening sequence, except for locking screws

adjacent to slit in clamp collar item "1", which should be torqued one after the other.

NOTES:

a) Since initial passes require almost no torque, even tightening is best achieved by turns approxi-

mately 90 degrees for each locking screw.

b) To compensate for bolt setting during installation, a 5% higher than specified tightening torque is

recommended for final tightening round.

5. After completion of installation, check all locking screws again in a clockwise (or counter-clockwise)

sequence and make sure no screw can be turned at specified tightening torque M

A

.

It is not necessary to recheck tightening torque after equipment has been in operation.

NOTE:

In installations subjected to extreme corrosion, the slits in clamp collars item "1" and "2" as well as in

center collar item "3" should be sealed with a suitable caulking compound or otherwise.