MAINTENANCE

Maintenance Section 5-4

© 2005 Alamo Group Inc.

GRIZZLY 66 01/05

Bikon Hub

1. Read and be familiar with the Bikon Lock Instructions.

2. Dismantle new Bikon Lock. Clean off preserving oil with rag.

3. Clean shaft end and bore of Bikon Lock.

4. Apply light coat of machine oil to shaft and Bikon Lock bore.

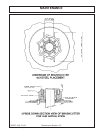

5. Re-assemble Bikon Lock assembly taking care that slits in all components are in line and the near and far

collars are not reversed.

6. Take two 3/8" square spacer bars and lay them on the shroud support plate on either side of the shaft.

7. Put hub on shaft up against the spacer bars. NOTE: Threaded holes face out.

8. Slide Bikon Lock over shaft and inside hub until it rests against the spacer bars.

9. With a marker pen mark torquing sequence on hub face to match Bikon Lock instructions, per Figure 1.

10. Tighten bolts to specified torque (Table 1) in several stages following the numbered sequence. You

must go around at least three times before reaching this value.

11. Remove spacer bars.

12. Install retaining ring and Spirol Lock Ring. Make sure ring seats in groove.

13. Mount cutter disk on hub and rotate until holes line up.

14. Place dust cover on hub and insert bolts with lockwashers. Torque to specified value in Table 2.

- Remove shaft complete with upper bearing from bearing housing. Remove bearing from shaft.

- Using a large pair of snap ring pliers, remove retaining ring from housing.

- Remove lower cover and lower bearing from housing.

- Wash all parts in solvent and inspect carefully for damage or excessive wear. Magnaflux the shaft while

disassembled.

- As a general rule, always use new oil seals and lockwashers when re-assembling.

- When ordering replacement parts, refer to the parts list and ensure that all parts other than fasteners, seals,

and bearings are genuine ALAMO parts. DO NOT use substitutes.

Assembly

- Pack the bearings with grease.

- Press the lower bearing onto the shaft, then press the shaft and bearing into the bearing housing from the

bottom.

- Press the upper bearing into the bearing housing and onto the shaft.

- Press the oil seal into the lower cover, apply gasket compound to the cover and secure in place with the

retaining ring.

- Pump six to eight shots of grease into each bearing while rotating.

- Install spacer onto shaft.

- Press oil seal into upper cover, apply gasket compound to cover, and then bolt cover to bearing housing.

- Position the lockwasher and then tighten the locknut onto the shaft.

- Place housing assembly into frame and bolt securely.

- Install motor mount plate. Set plate into its original dowel holes and check the maximum runout on the bore

compared to the shaft, if over .020" then the motor mount plate must be re-dowled. If not over .020", bolt in

place. If re-doweling is required, ensure there is no rocking of the motor mount plate, if so, grind the upper

frame to fit prior to re-doweling.

- Install motor. Using Loctite, torque motor mount bolts to required values and wire lock heads.