Operation 17

MAN0506 (Rev. 9/5/2008)

Keep bystanders away from equipment.

1. Clear the area of all bystanders.

2. Attach the 3-point hitch to the unit but not the PTO

driveline.

3. Raise the unit until the tractor PTO and gearbox

shafts are the same height.

4. Measure the dimension between the shaft grooves

on the tractor and implement ends. If this

dimension is less than 34.81 inches, the shaft will

require shortening.

5. Move the unit to its highest and lowest working

position and measure this dimension again. [The

unit’s shaft can telescope (see Figure 6) before it

has been shortened.]

6. If required, shorten the shaft to prevent bottoming

out during use. NOTE: An extra inch of

compression space in the shaft can eliminate

bottoming out during use. Measure to make sure.

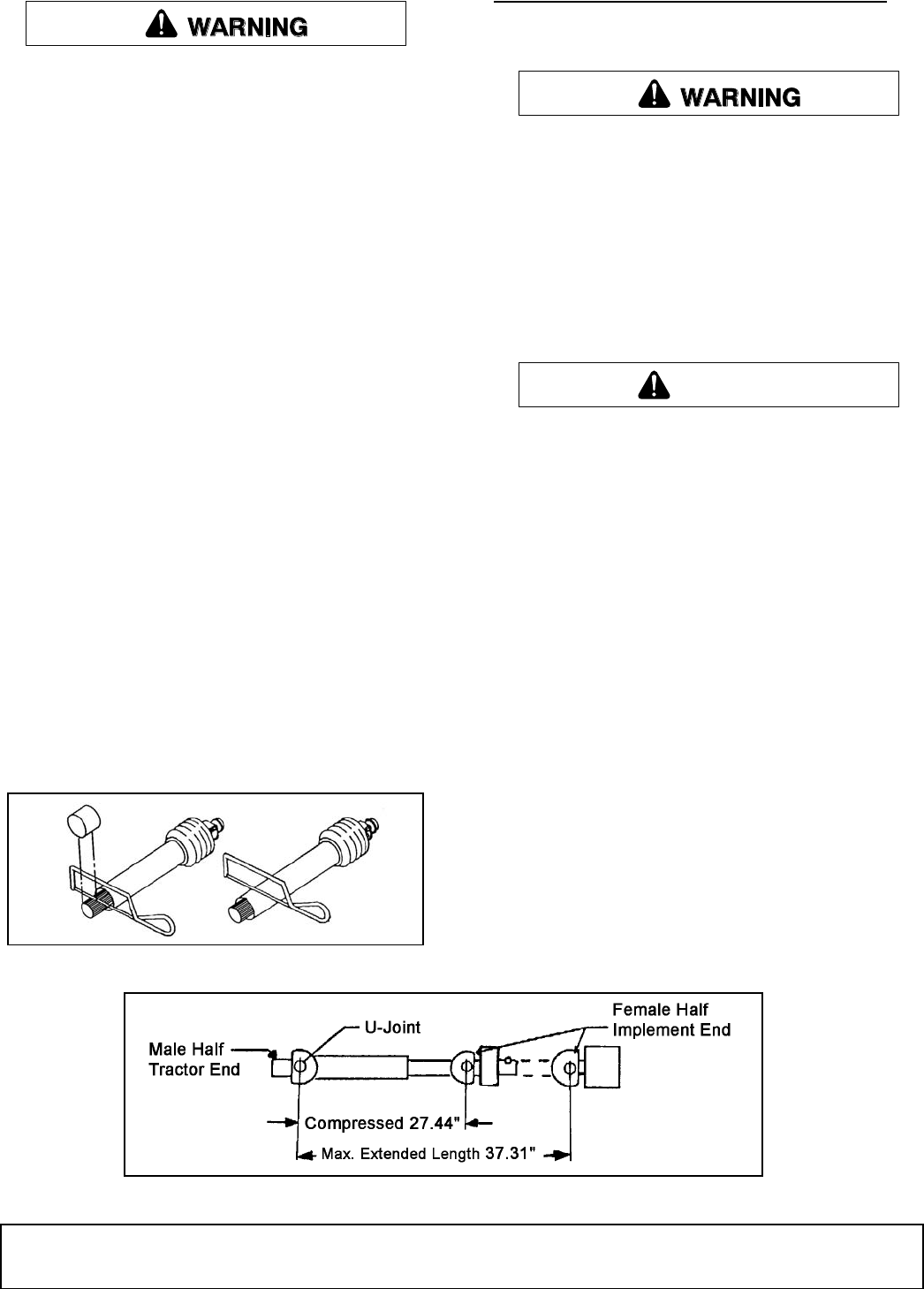

7. Use an abrasive wheel power saw to cut the male

end of the shaft. Cut the same amount from both

the splined shaft and the safety shield. See Figure

5. Use a file to remove any burrs from the cut end.

NOTICE

■ Cut only the male end. Never cut the female end.

8. Never cut more than 9 inches from the male end.

Cutting 1 inch from the male end shortens both the

minimum and maximum lengths by 1 inch.

Figure 5. Cutting the Driveline Shaft

ATTACHING SHREDDER TO TRACTOR

1. Place unit on a level, dry area free of debris and

other foreign object.

Keep bystanders away from equipment.

Connect PTO driveline directly to power unit

PTO shaft. Never use adapter sleeves or adapter

shafts. Adapters can cause driveline failures due to

incorrect spline or incorrect operating length and

can result in personal injury or death.

2. Clear the area of bystanders, especially children.

3. Provide enough clearance to back the tractor

safely into the unit.

■ Do not allow anyone to stand between tractor

and unit when backing up to the unit.

With Quick Hitch Attachment:

4. Set the height of the 3-point hitch so that quick

hitch claws are lower than the mounting pins.

5. Make sure 3-point hitch is set in the non-sway

position. See tractor manual for details.

6. Align the claws under the lower and upper mast

mounting pins while backing up.

NOTE: For a Category II hitch, use the bottom

upper mast hole. For a Category III hitch, use the

top upper mast hole.

7. When the claws are under the pins, slowly raise

the 3-point hitch. Make sure each mounting pin

seats in its respective claw.

8. Release the claw retainer locks to secure the

mounting pins in the claws.

9. Check the top link frame. It should be free to slide

in its mounting slots. This movement allows the

unit to follow the ground contour when cresting a

hill or going through a depression.

Figure 6. Driveline Dimension

CAUTION