Troubleshooting 35

MAN0506 (Rev. 9/5/2008)

TROUBLESHOOTING

The Woods Flail Shredder uses swinging flails to pick up and shred crop residue left in the field. It is a simple and reli-

able system that requires minimal maintenance.

The following table lists problems, causes, and solutions that you may encounter. If you encounter a problem that is dif-

ficult to solve even after reading through this table, please call your local Woods dealer. When calling, please have this

manual and your unit’s serial number ready.

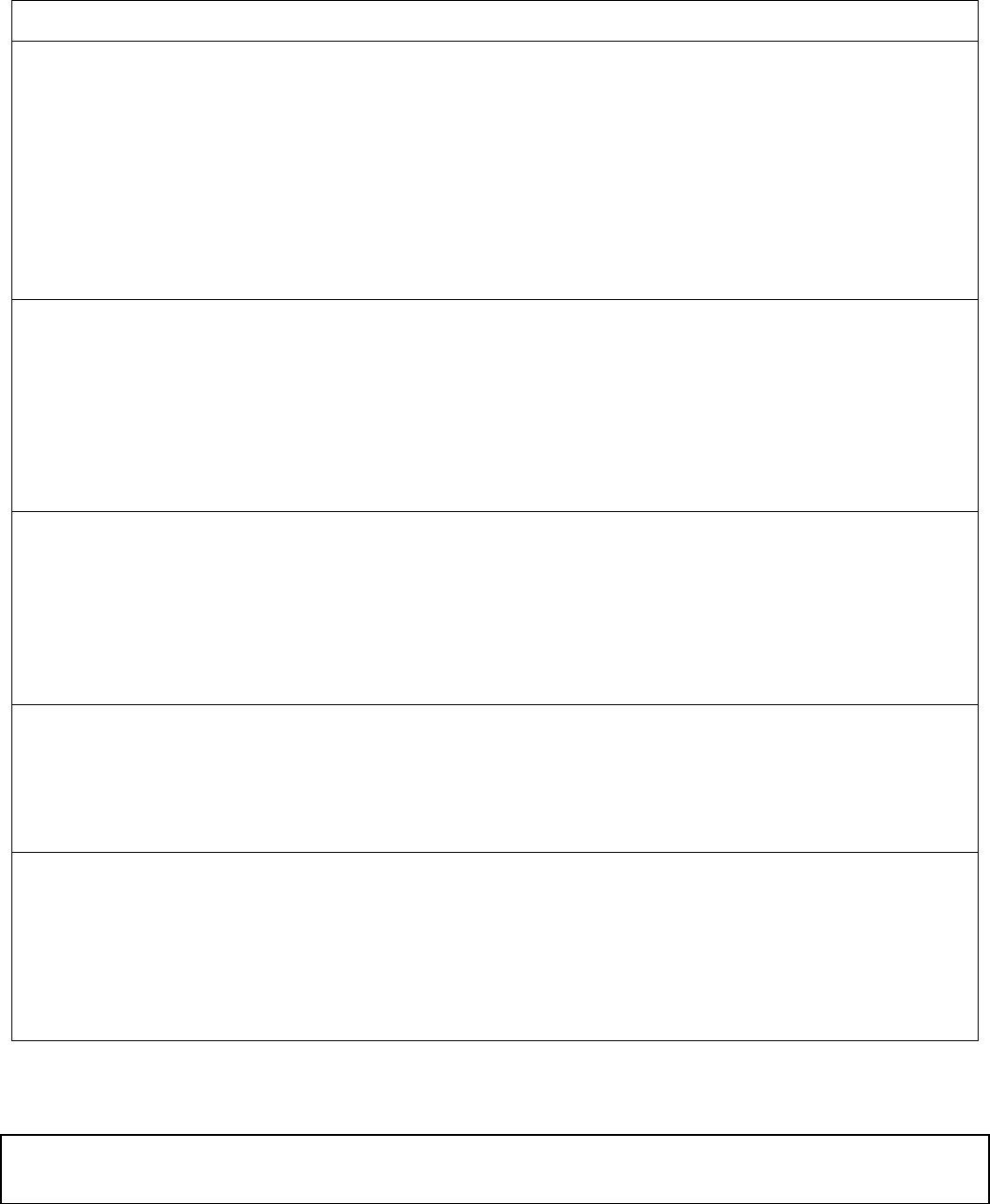

PROBLEM CAUSE SOLUTION

Shredder doesn’t track Poor wheel spacing Set wheels in center of crop rows.

3-Point not set Set 3-point hitch in non-sway

position.

Shredder not level Level shredder (see Set Operating

Height, page 20).

Irrigation furrows not even Set wheels against seed bed (see

Setting Outer Trailing Wheels

(Casters & Struts), page 21).

Shredder doesn’t follow

ground contour

3-Point not set Set 3 point in float position.

See tractor manual to set Load

Sensing hydraulic system.

Shredder too high Set shredder closer to ground.

Irrigation furrows not even Set wheels against seed bed.

Shredder vibrates Driveline doesn’t telescope. Remove, disassemble, and clean

telescoping joint.

Rotor out of balance Replace damaged or broken flails

and flails 180 degrees opposite.

Check for missing balance weights or

rebalance.

Debris is being thrown out

from under shredder

Shredder set too low Raise shredder.

Knives excessively worn Replace knives.

Rubber shields missing Replace flaps immediately.

Crop residue is being left Traveling too fast Slow travel speed.

Shredder too high Lower shredder.

Improper flails Change flails.

Crop residue strip left in shredder

center

Add center cutter or divider.