Service & Maintenance 33

MAN0506 (Rev. 9/5/2008)

NOTE: The shaft is heavy. Grasp the clutch firmly

with both hands and slide off the input shaft.

Rebuilding Friction Pack

Disassembly

1. Position clutch and universal joint assembly on a

bench so that end is accessible.

2. Remove the long bolts on the outside of the

housing that hold the friction pack together.

3. Remove the plate(s) and all internal components.

Leave the yoke/hub intact.

4. Discard friction discs.

5. If rebuilding the overrunning clutch, refer to

Rebuilding Overrunning Clutch, page 33,

beginning with Step 2.

Inspection

1. Inspect the steel and iron parts for wear, warping,

or cracks, and replace if necessary.

2. Inspect the yoke/hub for looseness. If there is more

than.03 end play, replace.

3. Clean any rust or dust from the plate surfaces with

a wire brush or steel wool.

Assembly

1. Place one new friction disc, then separator plate,

then second friction disc into housing.

2. Add the pressure plate so that the flat surface rests

on the friction disc. NOTE: The tangs on the plate

must fall into the reliefs in the housing.

3. Add the disc spring so that its inside diameter

contacts the fins of the pressure plate.

4. Assemble the compression plate and all the long

bolts. Make sure all nuts rest in their pockets.

5. Tighten all long bolts to 30 lbs-ft.

Rebuilding Overrunning Clutch

Disassembly

1. Remove the four bolts that secure the friction pack.

Remove the friction pack.

2. Using screwdriver and pliers, remove the retaining

ring that holds the overrunning clutch together.

3. Slide the collar and washer off the clutch hub,

noting the orientation of the collar for reinsertion.

4. Remove and discard the keys and leaf springs.

Inspection

1. Inspect the steel parts for wear and replace if

necessary.

2. Inspect the yoke/hub for looseness. If there is more

than .03 end play, replace.

3. Using screwdriver, scrape any hardened grease

from the overrunning key pockets.

Assembly

1. Using a multi-purpose high-temperature EP grease

or equivalent lithium grease, inject one grease gun

pump into each key pocket. Evenly wipe two more

pumps over the overrunning surface.

2. Press a new leaf spring into each pocket. The ends

should touch the bottom of the pockets.

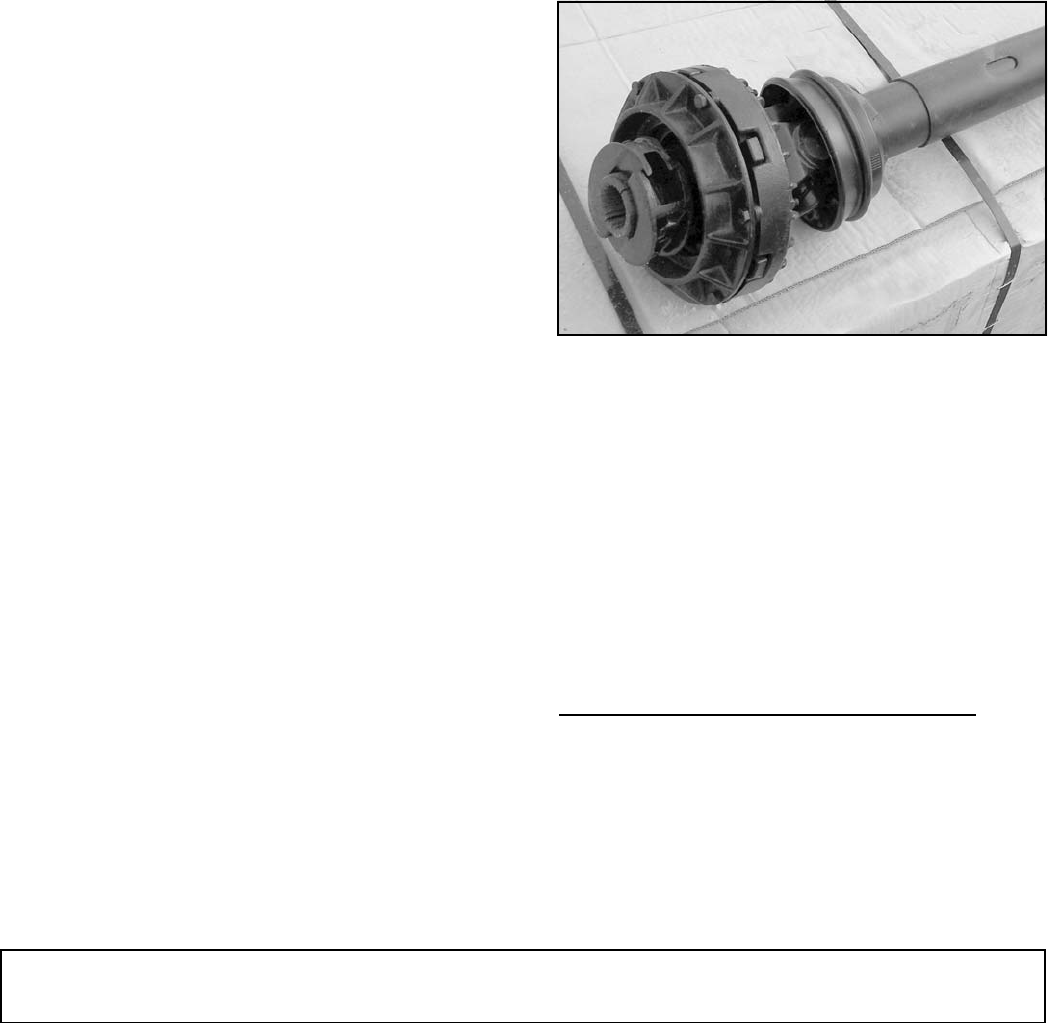

Figure 39. Weasler Modular Friction Clutch (24K)

3. Add new keys. With one hand, hold the two keys in

the pockets.

4. Slide the collar onto the hub, orienting collar

correctly.

5. Add washer.

6. Install retaining ring.

7. Make sure clutch spins freely and only in correct

direction.

8. Reassemble friction pack.

MOUNTING CLUTCH TO SHREDDER

1. Mount and bolt the clutch hub onto the shredder

input shaft. Make sure shaft and clutch grooves

line up.

2. Re-install any shielding that was moved or

removed.

3. Run the clutch before using. Refer to Breaking In

the Clutch (Run In), page 32.