8 Operation

29936 (Rev. 5/18/2007)

Figure 1. Attitude Adjustment

NOTICE

■ Improper belt alignment or tension can cause

premature belt failure.

LUBRICATION

Grease caster pivot and wheel every 8 hours of opera-

tion. There are grease fittings on each of the three

blade spindles. These are accessible without shield

removal. Grease every 24 hours of operation with a

good grade light to medium grease gun.

NOTICE

■ Do not over grease spindles. Excess grease

could be transferred to the belt and cause slippage

or premature failure.

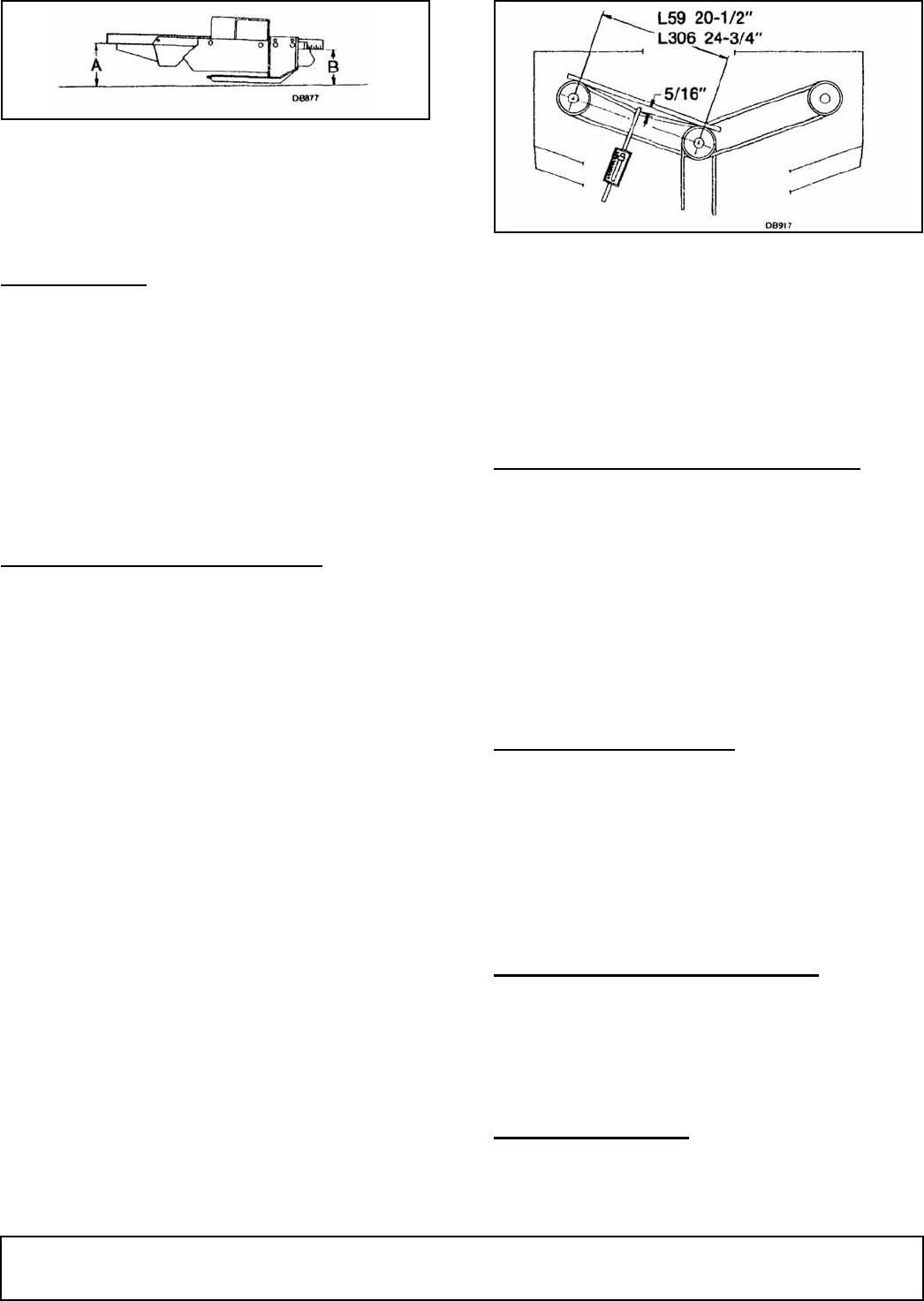

BELT TENSION (SEE FIGURE 2)

Set belt tension using a spring scale or other force

measuring device. Remove left belt shield. Attach scale

between cutter and left pulley. Apply between three

and four pounds of force. Belt deflection should mea-

sure 5/16" for normal conditions.

Tension may be increased if necessary to prevent belt

from slipping in heavy mowing conditions.

When checking tension without a force measuring

device, the belt, when properly set, should feel very

tight.

Cycle belt through at least two revolutions after any

adjustment before checking tension. These belts are

very strong and need to be adjusted very tight. Belts

are more likely to be damaged by excessive slippage

then from being overtightened.

NOTICE

■ Belt must not rub deck or crosswise support.

Tension adjustments may be made by moving the idler

pulleys up or down.

Figure 2. Proper Belt Tension

NOTICE

■ Alignment must be rechecked if it is necessary

to move idler pulleys to get proper belt tension.

■ Tension on a new belt should be readjusted

every half hour for the first two hours and then

checked every eight hours of operation.

SIDE SHIELD & DISCHARGE CHUTE

Side shield and discharge chute are provided for dis-

charge end of mower (left end on white frames and

right end on yellow frames). Use side shield for normal

mowing and in areas where other persons may be

present. Use discharge chute for very heavy mowing

conditions.

NOTICE

■ Always use either side shield or discharge

chute.

OPTIONAL EQUIPMENT

Optional equipment available includes casters for cut-

ting height control, front roller to minimize scalping, low

and extra suction blades, and a leaf mulcher. Low suc-

tion blades are for sandy areas where abrasive action

could cause excessive blade wear. Extra suction

blades are designed to lift up fragile downed grasses

for better cutting results and are also recommended for

use with Woods leaf mulcher attachment.

MOWER SPINDLE ASSEMBLIES

Mower spindle assemblies are equipped with two

tapered roller bearings. Bearing adjustment is held by a

roll pin. Adjustment should not be necessary. Repair

requires special skills and tools. You may save time

and money by using a new spindle assembly.

BLADE SERVICING

Keep blades sharp for a good mowing job. Sharpen

both ends of the blade the same amount to maintain

balance. Do not sharpen blade to a razor edge, but