Owner Service 25

MAN0390 (Rev. 4/6/2007)

SHIELDING REPAIR

Full chain or rubber shielding is required for all

non-agricultural mowing. Full shielding is also rec-

ommended for all agricultural use to further reduce

the risk of thrown objects.

Repairing Rubber Shielding

Inspect belting and rear bands each day of operation

and replace if bent, cracked, or broken.

Repairing Optional Chain Shielding

Inspect chain shielding each day of operation and

replace any broken or missing chains as required.

CLEANING

After Each Use

● Remove large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Inspect machine and replace worn or damaged

parts.

● Replace any safety decals that are missing or not

readable.

Periodically or Before Extended Storage

● Clean large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Remove the remainder using a low-pressure water

spray.

1. Be careful when spraying near scratched or torn

safety decals or near edges of decals as water

spray can peel decal off surface.

2. Be careful when spraying near chipped or

scratched paint as water spray can lift paint.

3. If a pressure washer is used, follow the advice of

the pressure washer manufacturer.

● Inspect machine and replace worn or damaged

parts.

● Sand down scratches and the edges of areas of

missing paint and coat with Woods spray paint of

matching color (purchase from your Woods

dealer).

● Replace any safety decals that are missing or not

readable (supplied free by your Woods dealer).

See Safety Decals section for location drawing.

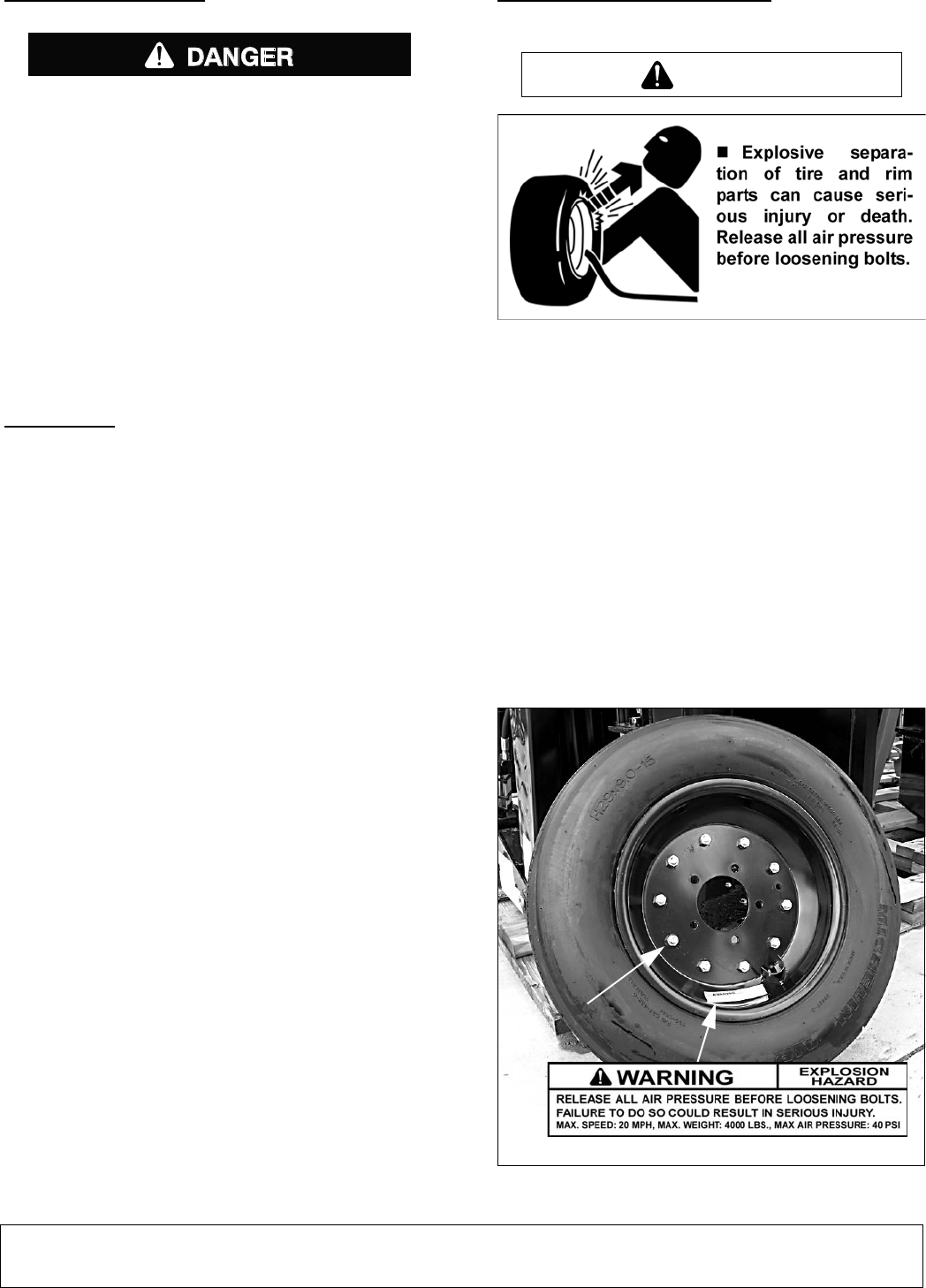

SERVICING TIRES SAFELY

Used Aircraft Tires (Figure 17)

Do not attempt to mount a tire unless you have the

proper equipment and experience to perform the job.

Always maintain the correct tire pressure. Do not inflate

tires above the recommended pressure. Never weld or

heat a wheel and tire assembly. The heat can cause an

increase in air pressure and result in a tire explosion.

Welding can structurally weaken or deform the wheel.

When inflating tires, use a clip-on chuck and an exten-

sion hose long enough to allow you to stand to the side

— not in front of or over the tire assembly. Use a safety

cage if available.

Check wheels for low pressure, cuts, bubbles, dam-

aged rims, or missing lug bolts and nuts.

Never remove split rim assembly hardware (A) with the

tire inflated.

Figure 17. Split Rim Tire Servicing

WARNING

A

DECAL PN 1006348

(Rev. 2/6/2009)