Owner Service 23

MAN0390 (Rev. 4/6/2007)

NOTE: Always replace or sharpen both blades at the

same time.

1. Inspect blade pin (12) for nicks or gouges, and if

you find any, replace the blade pin.

2. Insert blade pin through the blade (9). Blade

should swivel on blade pin; if it doesn’t, determine

the cause and correct.

3. Align crossbar (8) with blade access hole in cutter

frame. Apply a liberal coating of Never Seez or

equivalent to blade pin and crossbar hole. Make

sure blade offset is away from cutter. Push blade

pin through crossbar. Pin should rotate freely prior

to installing blade clip (15).

4. Install shims (13 & 16) over blade pin.

NOTE: Only use enough shims to allow keyhole

plate (14) to slide into blade pin groove.

5. Install blade clip (15) over keyhole plate and into

blade pin groove.

6. Secure into position with cap screw (35). Torque

cap screw to 85 lbs-ft.

7. Repeat steps for opposite side.

NOTE: Blade should be snug but should swivel on

pin without having to exert excessive force. Keep

any spacers not used in the installation as replace-

ments or for future installation.

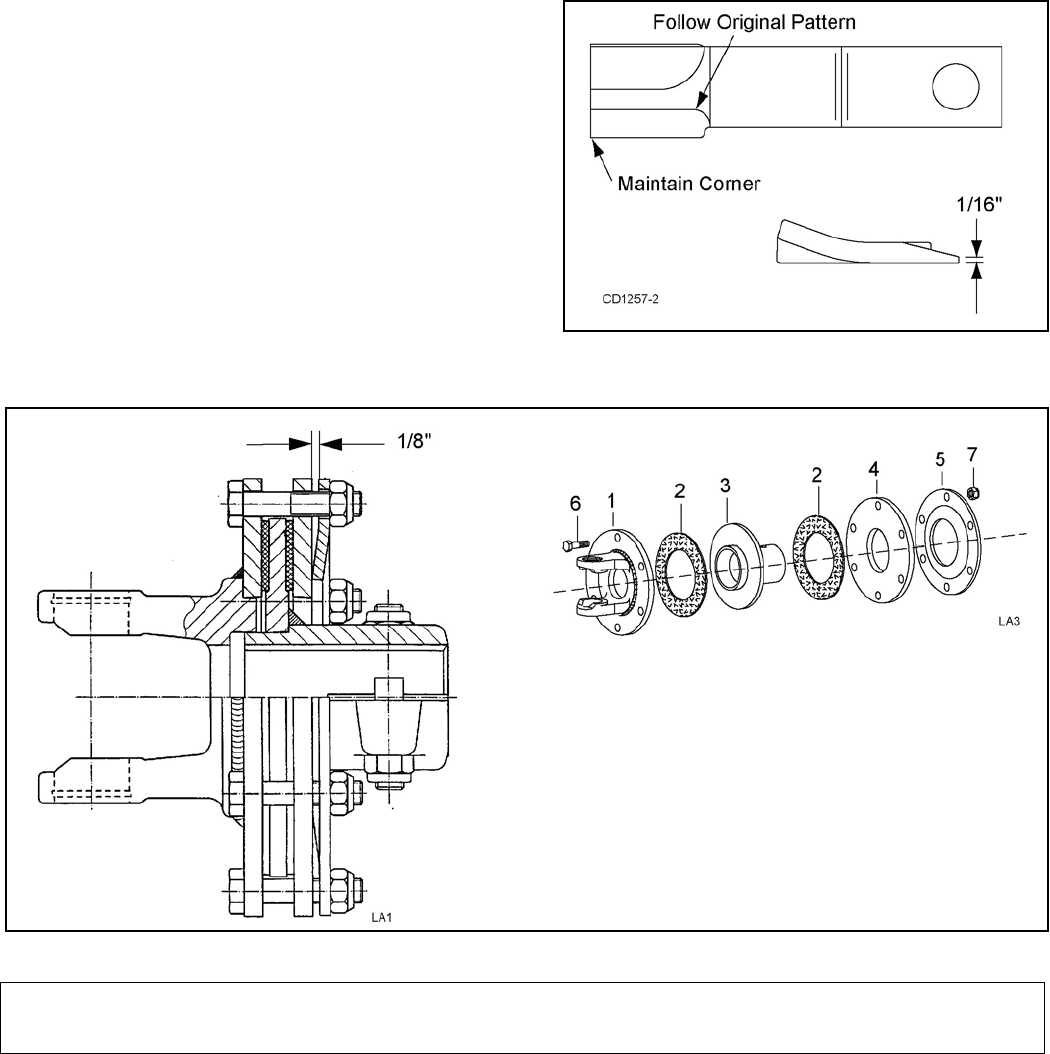

Sharpening Blades

NOTICE

■ When sharpening blades, grind the same

amount on each blade to maintain balance.

Replace blades in pairs. Unbalanced blades will

cause excessive vibration, which can damage

gearbox bearings. Vibration may also cause struc-

tural cracks to cutter.

1. Sharpen both blades at the same time to maintain

balance. Follow original sharpening pattern.

2. Do not sharpen blade to a razor edge—leave at

least a 1/16" blunt edge.

3. Do not sharpen back side of blade.

Figure 14. Sharpen Blade Cutting Edge

Figure 15. Slip Clutch Assembly

1. Flange yoke

2. Friction disc

3. Hub, 1-3/8 round bore

4. Thrust plate

5. Belleville spring plate

6. 10 mm x 1.35P x 50 mm Cap screw

7. 10 mm x 1.5P Hex nut

(Rev. 5/11/2007)