16 Operation

MAN0390 (Rev. 6/30/2006)

DS120 Category 2 Quick Hitch

1. Position the hitch pins as shown in Figure 4.

2. Attach tractor with quick hitch to cutter and secure

according to quick hitch manufacturer’s

instructions.

Figure 4. DS120 Category 2 Quick Hitch Connection

DS120 Category 3 Standard Hitch

1. Position the tractor 3-point lower lift arms between

the hitch mast plates and secure with hitch pins

and 7/16 klik pins. Note the hitch pins orientation.

2. Connect the tractor top link to the cutter A-frame

using the upper holes and 1-1/4" OD sleeve. The

break link must be placed in the lower holes of the

A-frame. See Figure 5.

Figure 5. DS120 Cat. 3 Standard Hitch Connection

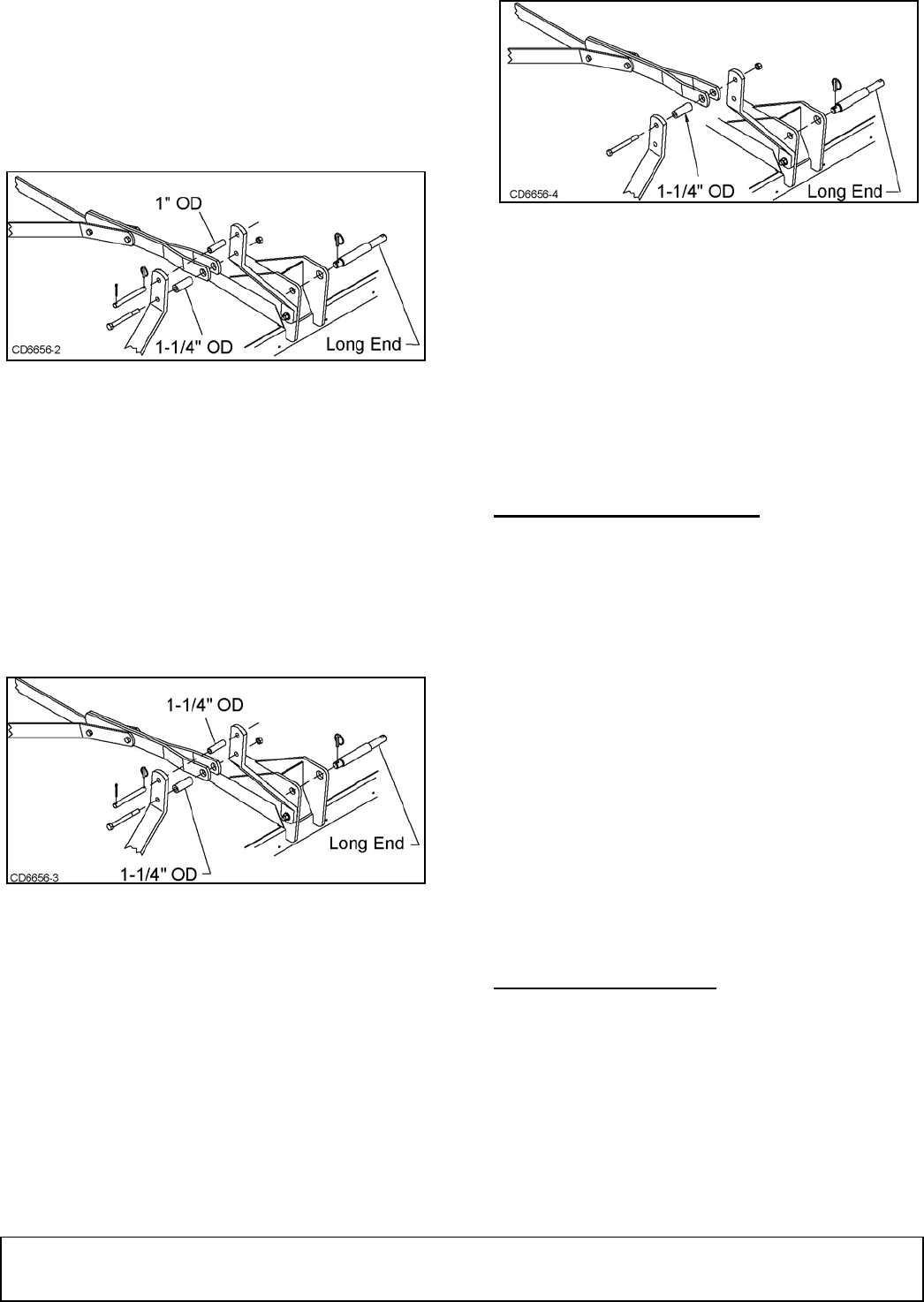

DS120 Category 3 Quick Hitch

1. Position the hitch pins as shown in Figure 6.

2. Place break link and 1-1/4" OD sleeve in the top

hole of the A-frame and secure.

3. Attach tractor with quick hitch to cutter and secure

according to quick hitch manufacturer’s

instructions.

Figure 6. DS120 Category 3 Quick Hitch Connection

Hydraulic Connection (DS120 Only)

1. Inspect hydraulic hoses to ensure they are in good

condition.

2. Clean the fittings before connecting them to the

tractor hydraulic ports.

3. Route hoses through hose holder on 3-point mast.

Be sure hoses can slide freely in holder. Do not

allow hose slack to drag on the ground or become

caught on tractor protrusions.

DRIVELINE ATTACHMENT

Attach the cutter to the tractor 3-point hitch (or quick

hitch if available). Do not attach driveline. Raise and

lower cutter to determine maximum and minimum dis-

tance between the tractor PTO shaft and the gearbox

input shaft. If the distance is too large, the driveline will

be too short for proper engagement. If distance is too

small, the driveline may bottom out in operation and

damage the cutter or tractor.

Driveline length must be sufficient to provide at least

1/3 driveline length of engagement during operation.

There must be at least 4 inches of engagement at the

cutters lowest possible point of operation. The driveline

must not bottom out when raised to the maximum

height possible.

If driveline is too short please call your Woods dealer

for a longer driveline.

If driveline is too long please follow the instructions for

shortening the driveline.

SHORTEN DRIVELINE

1. Move cutter up and down to get the shortest

possible distance between tractor PTO shaft and

gearbox input shaft.

2. Separate driveline into two halves and connect

them to the tractor PTO and gearbox.

3. Place driveline halves parallel to one another to

determine how much to shorten the driveline.

(Rev. 2/6/2009)