Dealer Service 29

MAN0450 (10/28/2005)

Disassemble

Remove snap ring (3) from end of barrel. Slide rod

assembly out of barrel. Inspect inside of cylinder barrel

and rod surface for any scratches or scouring. Small

scratches can be removed with fine crocus cloth. If

scratches cannot be repaired, replace entire cylinder.

Clamp cross pin end of rod assembly in vise. Remove

nut (5). Remove piston (1) and rod guide (2) from rod

assembly. Clean threads on rod assembly and nut.

Remove and discard all seals, wipers and O-rings.

Assemble

Lubricate new seals with clean oil. Install O-ring (D)

and backup washer (C) in the outer groove of rod guide

(2). Note the position of the backup ring. Install rod seal

(E) in inner groove of rod guide. Note that the lips of the

seal should be toward the piston side of the guide.

Install wiper (F) with lip pointed outward from rod guide.

Slide rod guide onto rod (6).

Install seal (A) onto outer groove of piston. Apply oil to

threads on rod assembly. Slide O-ring (4) over threads.

Install piston. Apply Loctite primer 7649 and removable

thread lock 242 to end of rod. Torque nut (5) to 150-180

lbs-ft.

Lubricate seals, slide rod assembly into tube and install

snap ring (3) to complete assembly.

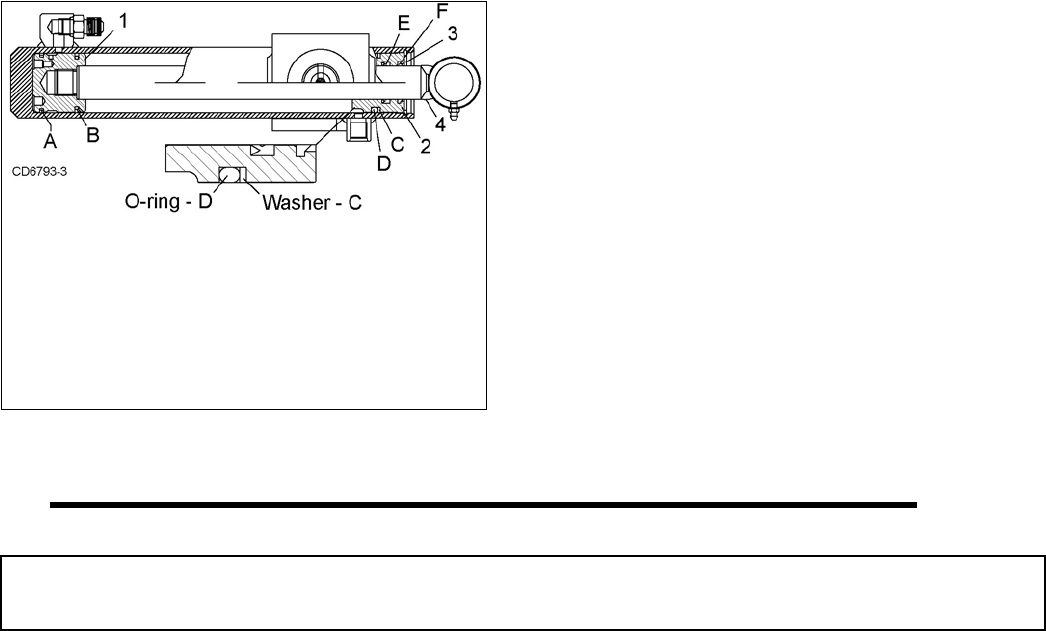

Swing Cylinder

Figure 19. Swing Cylinder

Disassemble

Check for style of rod guide and follow instructions in

corresponding section. Slide rod assembly out of bar-

rel. Inspect inside of cylinder barrel and rod surface for

any scratches or scouring. Small scratches can be

removed with fine crocus cloth. If scratches cannot be

repaired, replace entire cylinder.

Clamp cross pin end of rod assembly in vise. Remove

piston (1) from end of rod (4) using a spanner wrench.

Slide rod guide (2) from rod. Clean threads on rod

assembly and piston. Remove iron ring (A) from piston.

Remove and discard all seals, wipers and O-rings.

Assemble

Lubricate O-rings and seals with clean hydraulic fluid.

Install O-ring (D) and back-up (C) in exterior groove of

rod guide (2). Note the position of the backup washer

and O-ring. Install seal (E) and wiper (F) into inner

grooves of rod guide with open portion of V-groove

toward piston.

Slide rod guide assembly (2) onto rod (4). Place iron

ring (A) in outer groove of piston. Install piston seal (B)

in outer groove of piston.

Apply Loctite primer 7649 and removable thread lock

242 to threads on end of rod (4). Install piston (1) onto

rod and tighten with a spanner wrench. Torque to 150-

175 lbs-ft.

Compress iron ring and piston seal and carefully insert

piston and rod assembly into barrel. Use care to pre-

vent damage while installing.

Carefully push or tap rod guide (2) into barrel just past

groove inside barrel. Secure rod guide as shown for

the corresponding style.

1. Piston

2. Rod guide

3. Snap ring

4. Rod

A. Iron ring

B. Piston seal

C. Backup washer

D. O-ring

E. Rod seal

F. Wiper

(Rev. 8/5/2009)