32 Assembly

MAN0680 (11/30/2007)

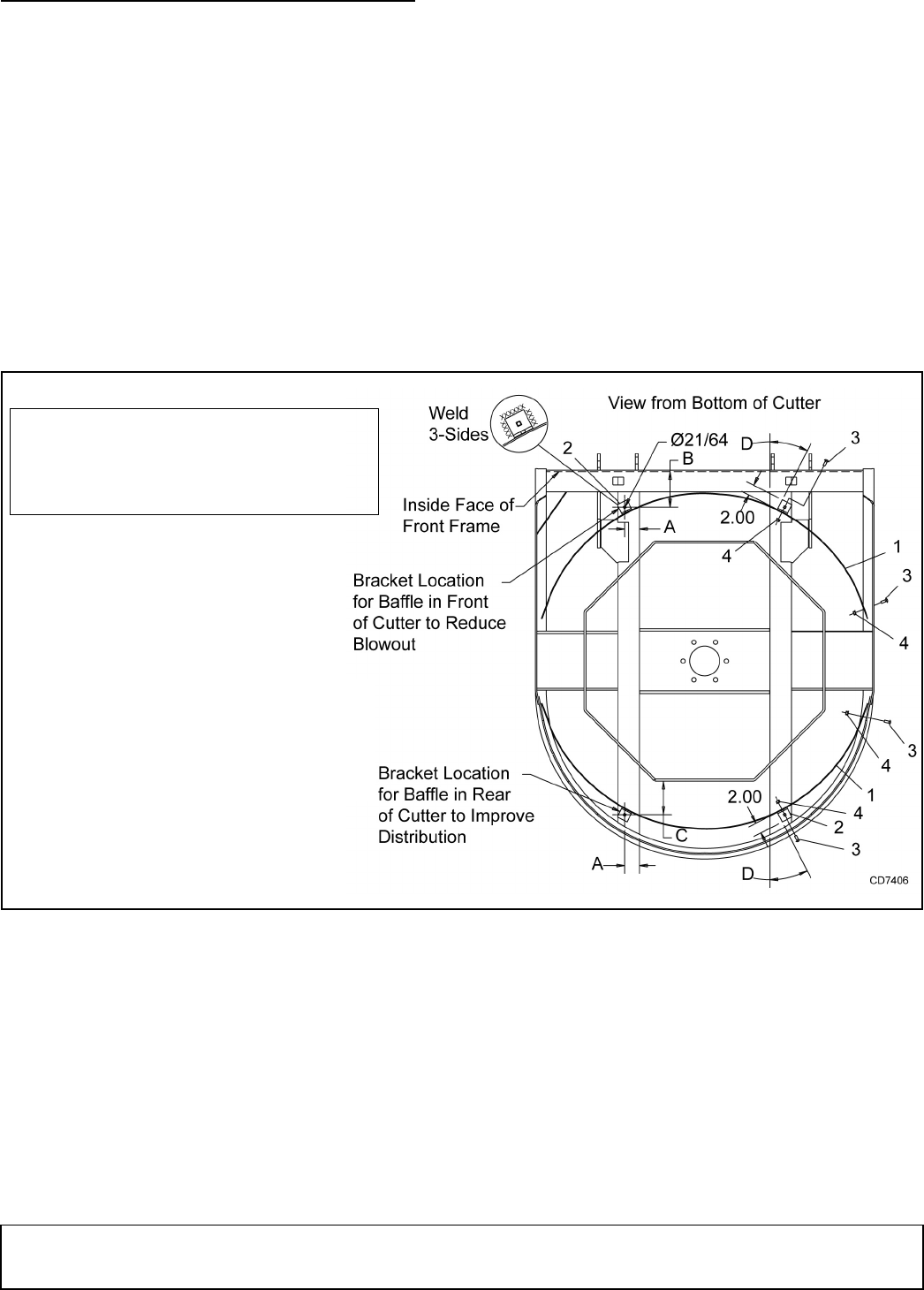

BAFFLE KIT INSTALLATION (OPTIONAL)

NOTE: An optional baffle kit may be installed to the

front of the cutter to prevent excessive blow-out when

cutter is used on a non-cab tractor. The baffle can also

be installed in the rear of the cutter to spread out dis-

charge.

1. From the bottom of the cutter, drill two 21/64" holes

in the rectangular tubes using dimensions A, B and

C from chart in Figure 34. Drill holes in either front

or rear of cutter.

2. Attach L-shaped mounting brackets (2) to the

bottom of the deck using self-tapping screws (5).

3. Place baffle (1) against mounting brackets (2) and

secure using two carriage bolts (3) and flange lock

nuts (4).

4. Baffles located in the front of cutter: Push end of

baffle against cutter side frame drill hole through

side frame using hole in baffle as a guide. Secure

baffle to side frame using carriage bolts (3) and

flange lock nuts (4).

5. Baffle located in the rear of cutter: Secure baffle to

side frame using carriage bolts (3) and flange lock

nuts (4).

NOTE: Mounting brackets must be welded to the

deck, screws alone will not be enough to hold

mounting brackets in place.

6. Weld mounting brackets to bottom of deck. Weld

solid on three sides.

Figure 34. Baffle Installation

1. Baffle kit, BB6000X, BB7200X, BB8400X

2. Mounting bracket

3. 3/8 NC x 1 Carriage bolt GR5

4. 3/8 NC Flange lock nut

Model ABCD

BB6000X 2.72" 6.56" 6.22" 27°

BB7200X 2.45" 5.99" 8.32" 22.5°

BB8400X 2.32" 5.23" 10.55" 19°