Owner Service 19

MAN0680 (11/30/2007)

BLADE SERVICE

Blade Removal

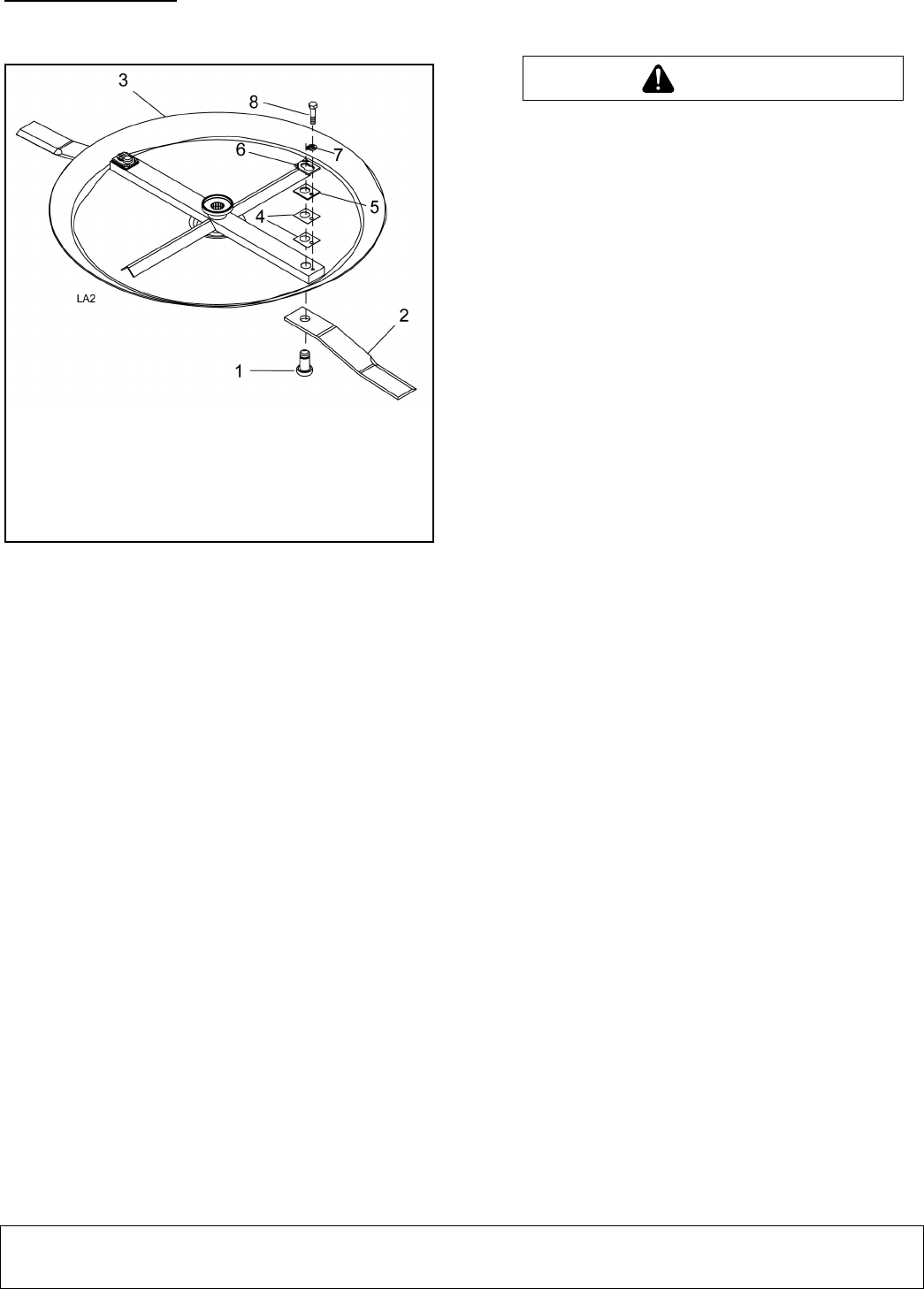

Figure 13. Blade Assembly

NOTICE

■ If blade pin (1) is seized in crossbar and

extreme force will be needed to remove it, support

crossbar from below to prevent gearbox damage.

1. Disconnect driveline from tractor PTO.

2. Raise cutter and block securely (see Figure 11).

3. Open blade access cover and align crossbar

assembly (3) with blade access hole in the cutter

frame. Remove cap screw (8) blade pin lock clip

(7) keyhole plate (6) and shims (5 & 4). Carefully

drive blade pin out of crossbar.

4. Rotate crossbar and repeat for opposite blade.

Blade Installation

Refer to Figure 13.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

NOTICE

■ Crossbar rotation is counterclockwise when

looking down on cutter. Be sure to install blade cut-

ting edge to lead in counterclockwise rotation.

■ Always replace or sharpen both blades at the

same time.

1. Inspect blade pin (1) for nicks or gouges, and if you

find any, replace the blade pin.

2. Insert blade pin through the blade. Blade should

swivel on blade pin; if it doesn’t, determine the

cause and correct.

3. Align crossbar assembly (3) with blade access hole

in cutter frame. Apply a liberal coating of Never

Seez

®

or equivalent to blade pin and crossbar

hole. Make sure blade offset is away from cutter.

4. Insert blade pin (1) through blade. Push blade pin

through crossbar.

5. Install shims (4 & 5) over blade pin.

NOTE: Only use enough shims to allow keyhole

plate (6) to slide into blade pin groove.

6. Install blade clip (7) over keyhole plate and into

blade pin groove.

7. Secure into position with cap screw (8). Torque cap

screw to 85 lbs-ft.

8. Repeat steps for opposite side.

NOTE: Blade should be snug but should swivel on

pin without having to exert excessive force. Keep

any spacers not used in the installation as replace-

ments or for future installation.

1. Blade pin

2. Blade

3. Crossbar assembly

4. 18ga x 1-1/2 Shim

5. 20ga x 1-1/2 Shim

6. Key hole plate

7. Blade pin lock clip

8. 1/2 x 1-1/4 Cap screw GR5

CAUTION