CLEAN

COOLING SYSTEII

-

Grass, chaff

or dirt

may

@d

the air cooling

system,

especially

after

prolonged

service cutting

dry

grass.

Yearly

or every

100 hours, whichever occurs

first, remove the

blower

housing and clean

the areas shown

-to

avoid over-

speeding, overheating

and engine

damage. Clean

more

often

if necessary.

DANGER: Periodically

clean

muffler

area to remove all

grass,

dirt and

combustible debris.

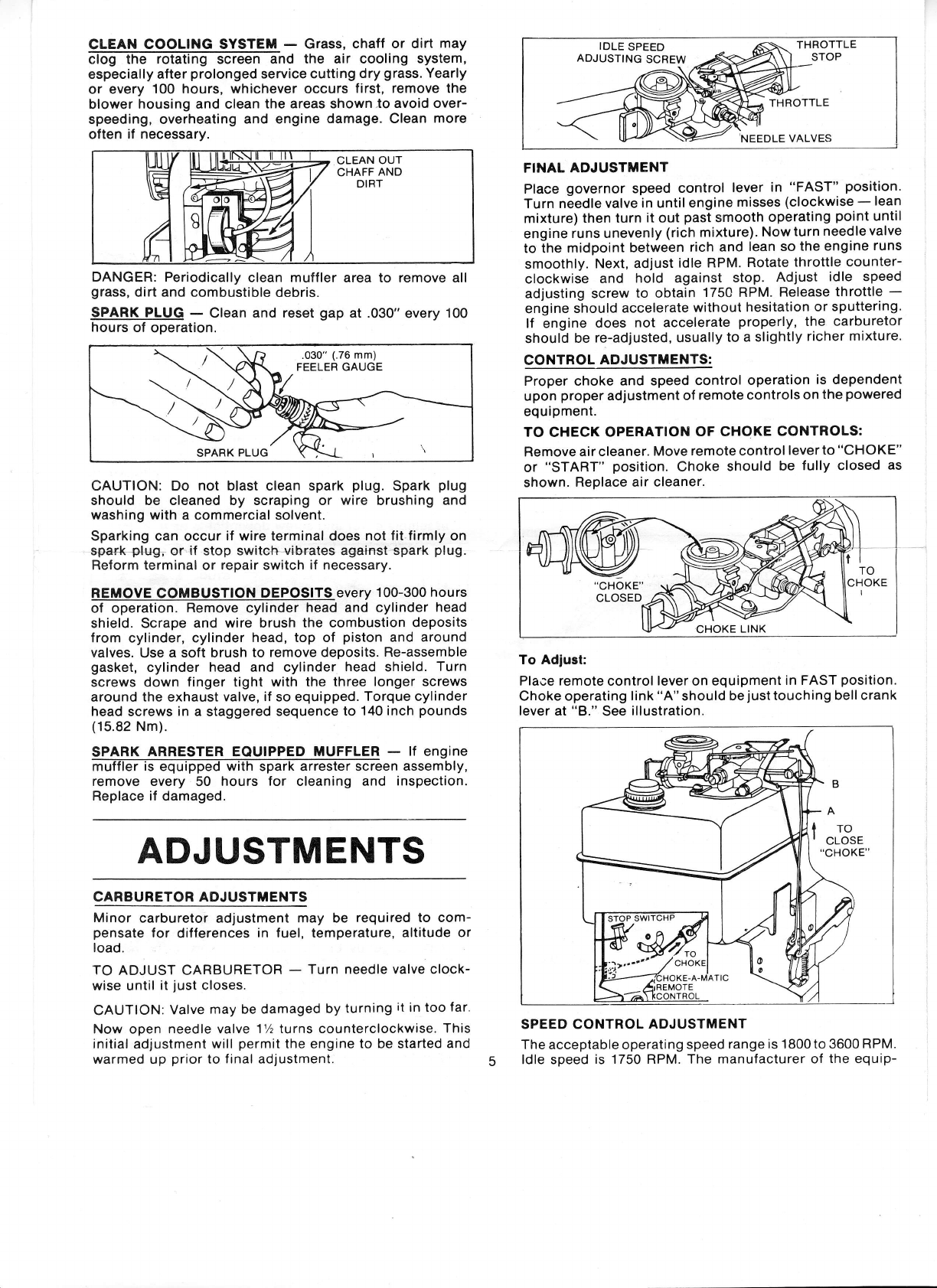

SPARK PLUG

-

Clean and reset

gap

at .030"

every

100

hours

of

operation.

CAUTION: Do not blast clean spark

plug.

Spark

plug

should be cleaned by scraping or wire brushing

and

washing

with a commercial solvent.

Sparking can occur

if

wire terminal does

not fit.firmly on

spa+t<

ptusi

or if stop switetr+ib+ates agai+st spark

plug.

Reform terminal

or

repair switch

if

necessary.

REMOVE COMBUSTION

DEPOSITS

every

100-300 hours

of operation.

Remove

cylinder

head and

cylinder

head

shield. Scrape and

wire brush the combustion

deposits

from cylinder, cylinder

head, top of

piston

and around

valves.

Use

a soft brush

to remove deposits.

Re-assemble

gasket,

cylinder head and cylinder

head

shield.

Turn

screws down

finger tight with

the three longer screws

around

the

exhaust

valve,

if

so equipped.

Torque cylinder

head

screws

in a

staggered

sequence

to

140 inch

pounds

(15.82

Nm).

SPARK

ARRESTER

EOUIPPED

MUFFLER

-

lf engine

en assemblY,

remove every 50 hours for cleaning and

inspection.

Replace if

damaged.

ADJUSTMENTS

CARBURETOR ADJUSTMENTS

Minor

carburetor

adjustment

may be

required to com-

pensate

lor

differences

in fuel, temperature, altitude

or

load.

TO

ADJUST CARBURETOR

-

Turn needle

valve clock-

wise until

it

just

closes.

CAUTION:

Valve

may

be

damaged

by

turning

it

in

too far'

Now open needle valve

172 turns counterclockwise.

This

initial adjustment

will

permit

the engine to be started

and

warmed up

prior

to

final adjustment.

FINAL ADJUSTMENT

Place

governor

speed

control

lever

in

"FAST"

position.

Turn

needle

valve in until engine

misses

(clockwise

-

lean

mixture)

then turn

it out

past

smooth

operating

point

until

engine

runs unevenly

(rich

mixture).

Now

turn

needle

valve

to the

midpoint

between

rich and

lean so

the engine

runs

smoothly.

Next, adiust

idle

RPM.

Rotate

throttle

counter-

clockwise

and

hold against

stop.

Adjust

idle speed

adjusting

screw

to obtain

1750 RPM.

Release

throttle

-

engine

should

accelerate

without

hesitation

or

sputtering.

lf engine

does

not accelerate

properly,

the carburetor

should

be

re-adjusted, usually

to a slightly

richer

mixture.

CONTROL

ADJUSTMENTS:

Proper choke

and speed control

operation

is dependent

upon

proper

adjustment of

remote controls

on

the

powered

equipment.

TO CHECK OPERATION

OF CHOKE

CONTROLS:

Remove air cleaner.

Move

remote control

leverto

"CHOKE"

or

"START"

position.

Choke

should

be

fully closed

as

shown.

Replace air cleaner.

To Adjust:

Place remote control

lever

on

equipment

in FAST

position.

Choke operating link

"A"should

be

justtouching

bellcrank

lever

at

"8."

See

illustration.

SPEED CONTROL

ADJUSTMENT

The acceptable operating speed

range

is 1800to 3600

RPM.

ldle speed

is 1750 RPM. The

manufacturer of

the equip-

CLEAN

OUT

CHAFF

AND

DIRT

.030"

(.76

mm)

FEELER GAUGE

CHOKE

LINK