Maintenance Instructions REPLACING/REPAIRING

65

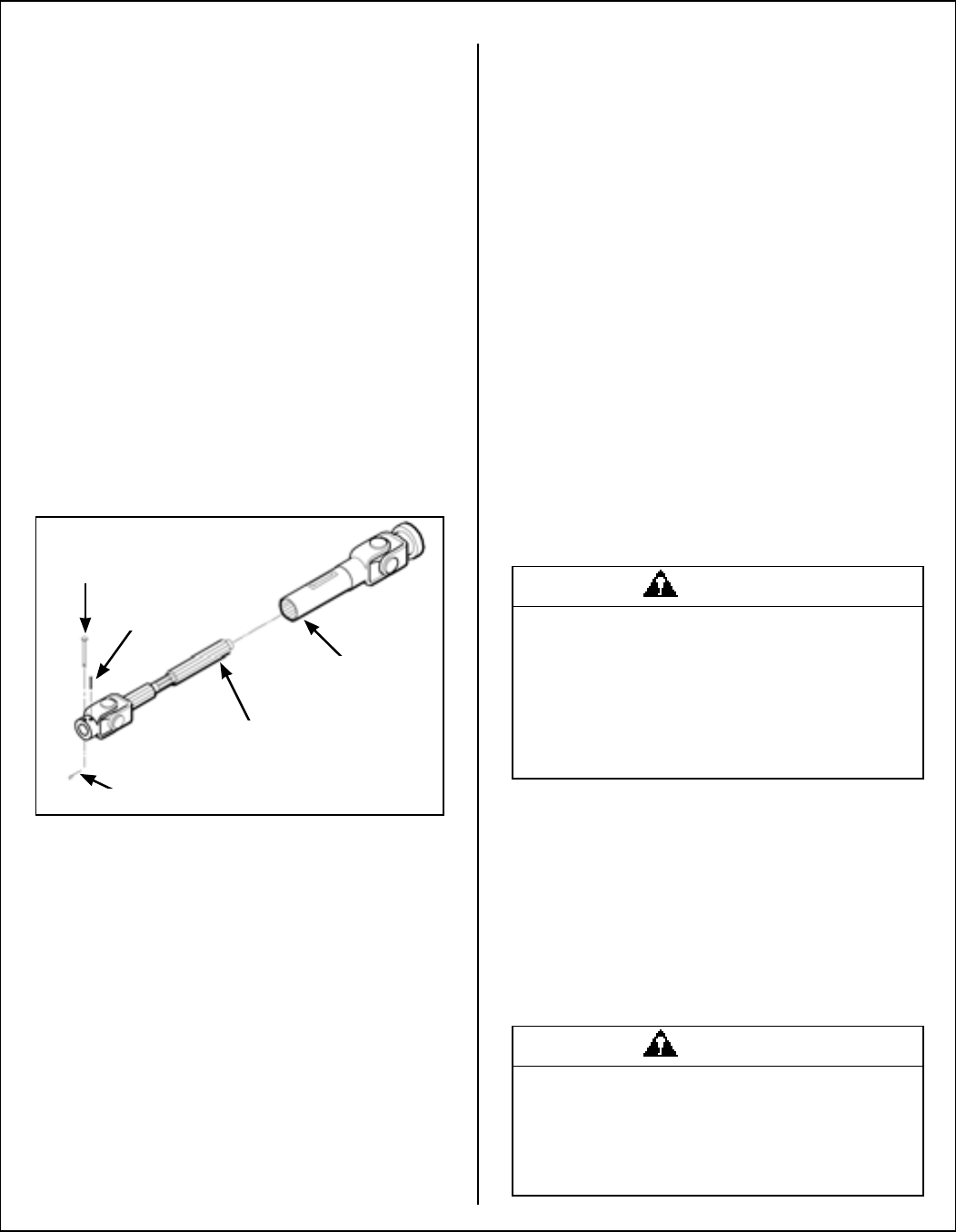

PTO Shear Pin

The PTO drive shaft connection to the deck gearbox

has a shear pin to provide shock load protection to

the mower deck drive. This system provides prima-

ry shock protection in case of blade impact and will

normally shear before the individual shear bolts on

the blade hub.

When the PTO pin has sheared, use the following

procedure to replace it:

1. Loosen the two bolts securing the PTO shaft

guard on the deck; lift the guard off. (Holes in

guard are slotted for easy removal.)

2. Rotate U-joint on shaft to align the shear pin

hole with the hole (and shear pin fragment) in

the shaft. Use a punch to drive the remaining

portion of the old shear pin out.

3. Install new shear pin and secure with cotter pin.

PTO Shear Pin

IMPORTANT: Use only Walker P/N 8067-13

shear pins for replacement to provide proper

shock protection -- these pins are hardened to

shear under a specific amount of load.

4. Reinstall the PTO shaft guard.

Before operating the deck, inspect the blade over-

load shear bolts and also check blade timing (on

gear driven decks) by moving blades through one

(1) complete revolution. Make sure blade tips pass

clear of each other. If timing is incorrect, contact your

Walker Dealer.

NOTE: Use Walker P/N 8067-10 for heavy duty

gearboxes.

Mower Blades

Mower blades are removed and remounted as de-

scribed in Sharpen Mower Blades instructions.

During the course of sharpening and inspecting

mower blades, if there are any of the following con-

ditions of wear or damage, blades should be re-

placed for reasons of safety and performance of the

machine:

• An excessive amount of the flat section of the

blade has been ground away (removed) when the

blade is sharpened. Replace the blade when less

than a 3/4 in. (19 mm) flat section remains at the

blade tip.

• Examine ends of the blade carefully, especially

the intersection where the flat section of the blade

turns up to form the “wing tip” (refer to Mower Blade

Profile for Sharpening illustration in Sharpen

Mower Blades instructions). Since sand and abra-

sive material can wear metal away in this area, the

blade should be replaced when metal thickness

has worn to 1/16 in. (1.6 mm) or less.

• Check the blades for straightness by marking

blade tip position inside the deck housing and then

rotating the opposite end of the blade to the same

position and comparing. If the difference in blade tip

track is more than 1/8 in. (3 mm), the blade is bent

and should be replaced.

• Inspect the blade surface, especially in formed

areas, for cracks. Replace the blade if any cracks

are found.

Cotter Pin

U-Joint

Tube Assembly

Shear Pin

Split Spring Pin

U-Joint

Shaft Assembly

DANGER

When blades are operated over sandy

soil, and if blades are allowed to wear, a

“slot” may be worn into the wing tip of

blade. Eventually a piece of the blade may

break off creating a serious potential for

injury or damage.

WARNING

DO NOT try to straighten a blade that is

bent. NEVER weld a broken or cracked

blade. ALWAYS replace with a new blade

to assure safety.