Maintenance Instructions LUBRICATION

45

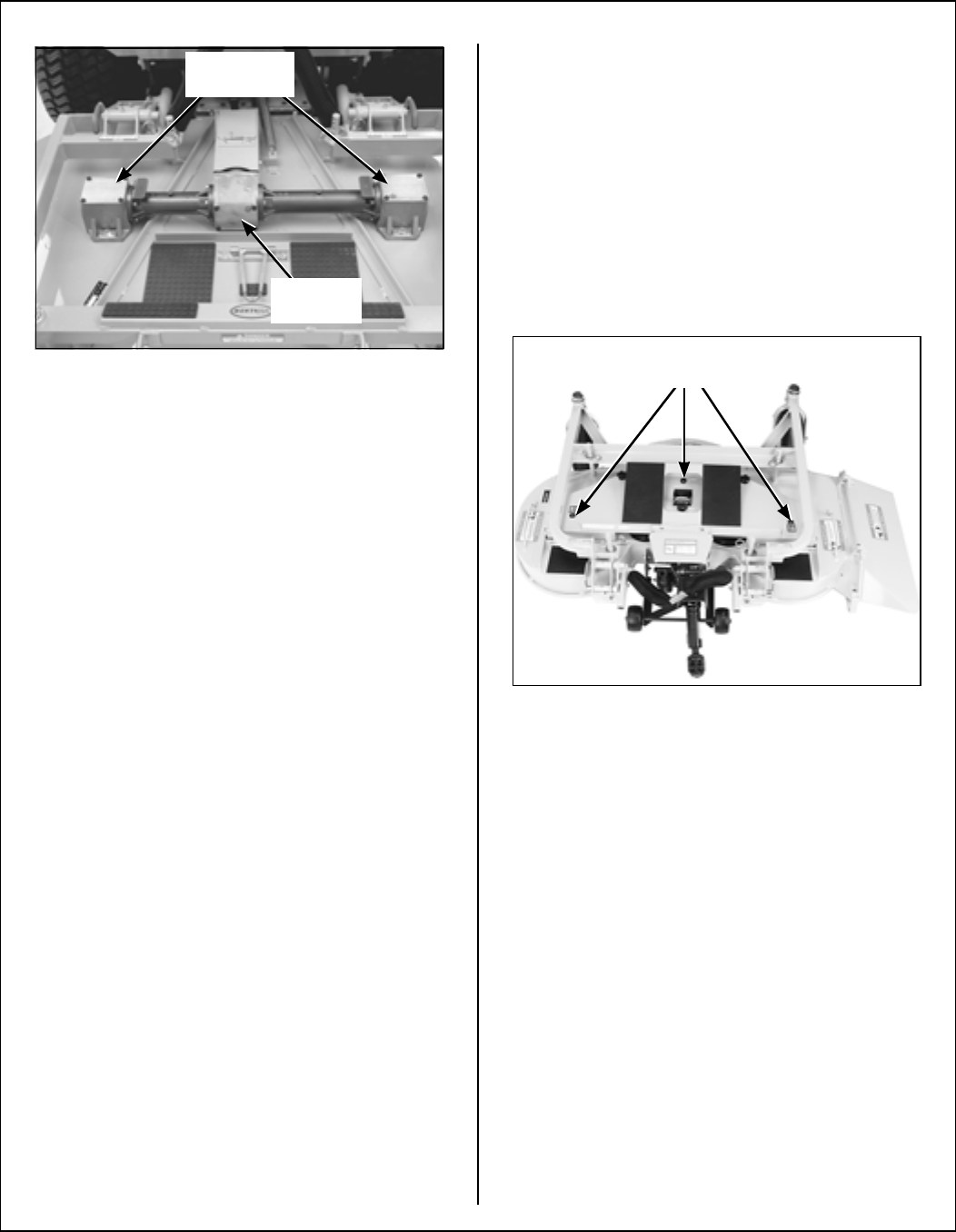

Mower Deck Gearboxes

(shown with gearbox cover removed for clarity)

2. Clean the area around the individual gearbox

cover plates to prevent contaminants from en-

tering the gearcase.

3. Remove the screws securing the cover plates

on the blade drive gearboxes.

4. Check the level of lubricant in the gearboxes. If

the lubricant is low, add SAE E.P. (Extreme

Pressure) 80W-90 oil until the oil level is up to

(submerges) the horizontal shaft in the gearbox

(shaft parallel to cover plate).

NOTE: In case the gearboxes are completely

drained of oil, approximately 5 fl. oz. (15 cl) of oil

per gearbox is required to refill the gear drive

assembly.

NOTE: Since the gearboxes are connected as

a unit by connector tubes, it is necessary to add

oil slowly. Allow a few minutes after adding oil

for the oil to flow throughout the assembly and

the oil level to stabilize before reassembly.

IMPORTANT: DO NOT overfill the deck gear-

boxes. The gearbox assembly is not vented,

and overfilling with oil will cause excessive pres-

sure and result in oil leaks.

5. Check condition of the cover gasket and replace

if worn or damaged. Reinstall gearbox cover

plates; torque screws to 24 in-lb (2.7 N

·m).

DSD52 Mower Deck Lubrication

There are several special lubrication requirements

for the DSD52 mower deck in addition to the require-

ments detailed in the Chassis and Deck Lubrica-

tion illustration. Lubricate the locations shown in

the Blade Spindle Lubrication and Gearbox, Dol-

ly Wheel, and U-Joint Lubrication photos and

check and maintain oil in the belt drive gearbox.

1. Lubricate the blade spindles every 25 hours

with two (2) shots of SAE general purpose lithi-

um or molybdenum base grease.

Blade Spindle Lubrication

2. Check the oil level in the belt drive gearbox ev-

ery 100 hours (or sooner if a visible oil leak has

developed). With the deck in the normal oper-

ating position, remove the level plug in the side

of the gearcase. Add SAE E.P. (Extreme Pres-

sure) 80W-90 gear lube to maintain the level to

the plug. If the oil level is low, check the gear-

box for any indication of an oil leak. If an oil leak

is noted, the gearbox will need to be removed

and rebuilt.

3. Lubricate the dolly wheel pivot every 25 hours

with general purpose grease.

4. Lubricate the U-Joint in the drive shaft every

8 hours with SAE general purpose lithium or

molybdenum base grease.

Blade Drive

Gearboxes

Tee

Gearbox

Blade

Spindles