MICROMATIC

®

AND

MicromaticHP

®

STANDARD

RESPONSE PENDENT

SPRINKLERS

TECHNICAL DATA

March 7, 2008

The Viking Corporation, 210 N Industrial Park Road, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-945-4495 Email: techsvcs@vikingcorp.com

TABLE 1: AVAILABLE SPRINKLER TEMPERATURE RATINGS AND FINISHES

Sprinkler Temperature

Classification

Sprinkler Nominal

Temperature Rating

1

Maximum Ambient

Ceiling Temperature

2

Bulb Color

Ordinary 135 °F (57 °C) 100 °F (38 °C) Orange

Ordinary 155 °F (68 °C) 100 °F (38 °C) Red

Intermediate 175 °F (79 °C) 150 °F (65 °C) Yellow

Intermediate 200 °F (93 °C) 150 °F (65 °C) Green

Intermediate 212 °F (100 °C) 150 °F (65 °C) Green

High 286 °F (141 °C) 225 °F (107 °C) Blue

Extra High 360 °F (182 °C) 300 °F (149 °C) Mauve

Ultra High

3

500 °F (260 °C) 465 °F (240 °C) Black

Sprinkler Finishes: Brass, Chrome-Enloy

®

, White Polyester, Black Polyester, and Black Teflon

®

Corrosion-Resistant Coatings

4

: White Polyester, Black Polyester, and Black Teflon

®

in all temperature ratings. Wax-Coated

Brass and Wax over Polyester

5

for sprinklers with the following temperature ratings:

135 °F (57 °C) Off-White Wax 155 °F (68 °C) Lt. Brown Wax 175 °F (79 °C) Brown Wax 200 °F (93 °C) Brown Wax

212 °F (100 °C) Dk. Brown Wax

6

286 °F (141 °C) Dk. Brown Wax

6

Footnotes

1

The sprinkler temperature rating is stamped on the deflector.

2

Based on NFPA-13. Other limits may apply, depending on fire loading, sprinkler location, and other requirements of the Authority Having

Ju

risdiction. Refer to specific installation standards.

3

Sprinklers of Ultra-High temperature rating are intended for use inside ovens, dryers, or similar enclosures with normal oper-

ating temperatures above 300 °F (149 °C). Where the ambient temperature around the Ultra-High temperature rated sprinkler

is significantly reduced below 300 °F (149 °C), response time may be severely retarded.

4

The corrosion-resistant coatings have passed the standard corrosion test required by the approving agencies indicated

on pages 11 d-e. These tests cannot and do not represent all possible corrosive environments. Prior to installation, verify

through the end-user that the coatings are compatible with or suitable for the proposed environment. For automatic sprinklers,

the coatings indicated are applied to the exposed exterior surfaces only. Note that the spring is exposed on sprinklers with

Polyester and Teflon

®

coatings. For Teflon

®

coated open sprinklers only, the waterway is coated.

5

Wax Over Polyester is unavailable for Sprinklers VK023 and VK122.

6

Wax melting point is 170 °F (76 °C) for 212 °F (100 °C) and 286 °F (141 °C) temperature rated sprinklers.

Sprinkler 11c

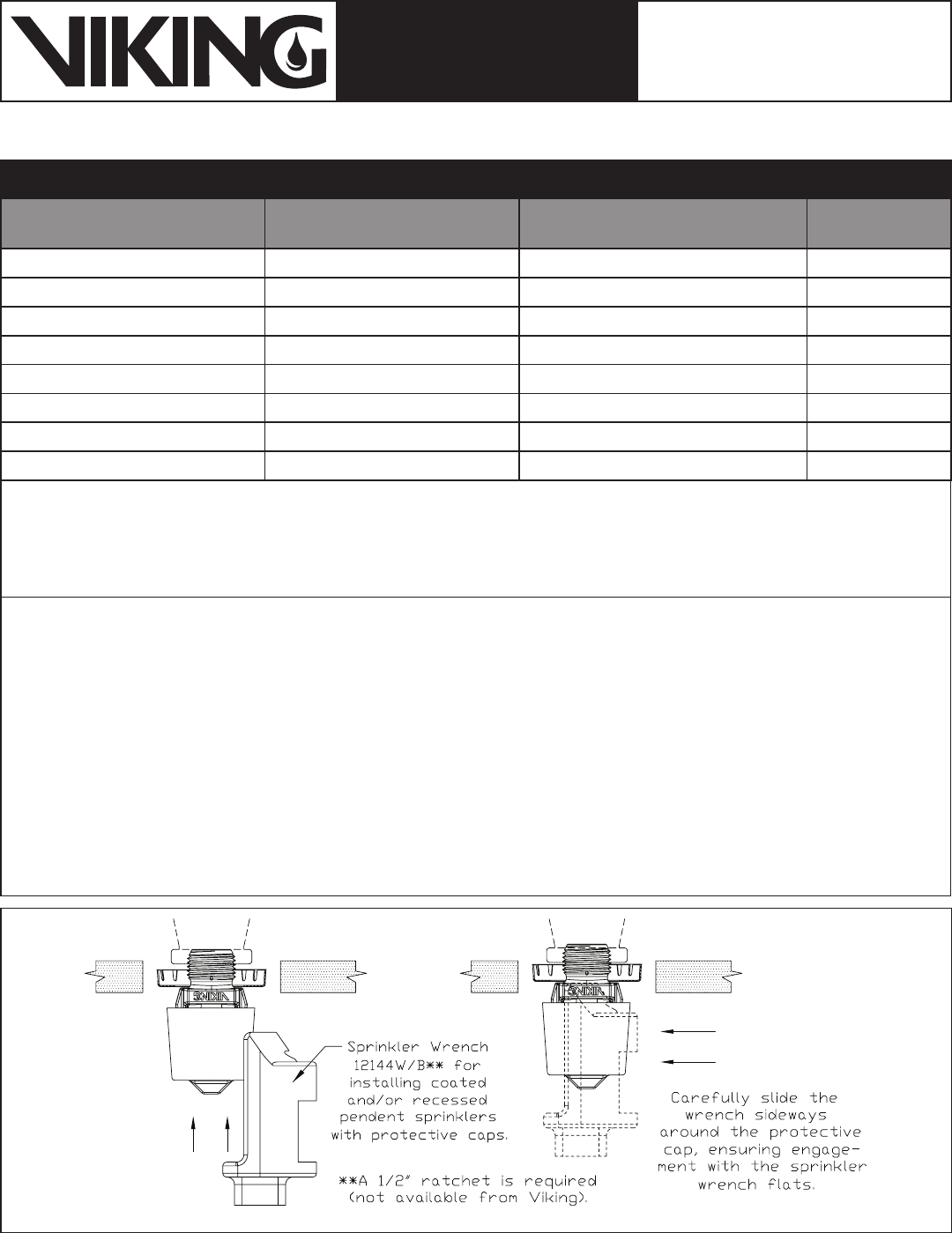

Figure 2: Wrench 12144W/B for Coated and/or Recessed Pendent Sprinklers