11

CHECKING THE OIL LEVEL

The importance of checking and maintaining the proper oil level

in the crankcase cannot be overemphasized. Check oil before

each use:

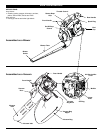

1. Stop the engine and allow oil to drain into the crankcase.

2. Place the engine on a level surface (Fig. 21).

3. Raise the rear of the unit 3.5 inches to get a proper oil level

reading (Fig. 21).

4. Clean the area around the dipstick before removing it. Keep

dirt, grass clippings, and other debris out of the engine.

5. Remove the oil fill plug.

6. Look into the oil fill hole (use a flashlight if needed). The oil

should be just touching the innermost thread (Fig. 22).

7. If the oil level is not touching the innermost thread on the

oil fill hole, add a small amount of oil to the oil fill hole and

recheck (Fig. 22). Repeat this procedure until the oil level

reaches the innermost thread on the oil fill hole.

NOTE: Do not overfill the unit.

NOTE: Make sure the O-ring is in place on the oil fill plug when

checking and changing the oil (Fig. 23).

Oil Fill Plug

Oil Fill Hole

O-Ring

Max Oil Fill Line

Fig. 23

Fig. 22

WARNING: To prevent serious injury, never

perform maintenance or repairs with unit running.

Always service and repair a cool unit. Disconnect the

spark plug wire to ensure that the unit cannot start.

FREQUENCY MAINTENANCE REQUIRED SEE

Before starting engine

Fill fuel tank with fresh fuel

Check oil

p. 7

p. 11

Every 10 hours Clean and re-oil air filter p. 12

1st change at 10 hours

2nd change at 25 hours

Every 25 hours after

Change oil

Change oil

Clean spark arrestor

p. 11

p. 11

p. 14

10 hours on new engine

Every 25 hours

Every 25 hours

Check rocker arm to valve clearance and adjust

Check rocker arm to valve clearance and adjust

Check spark plug condition and gap

p. 13

p. 13

p. 14

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should also

be a part of any seasonal tune-up.

NOTE: Some maintenance procedures may require special tools

or skills. If you are unsure about these procedures take

your unit to a qualified service dealer.

NOTE: Maintenance, replacement, or repair of the emission

control devices and system may be performed by a

qualified service dealer.

In order to assure peak performance of your engine, inspection

of the engine exhaust port may be necessary after 50 hours of

operation. If you notice lost RPM, poor performance or general

lack of acceleration, this service may be required. If you feel

your engine is in need of this inspection, refer service to a

qualified service dealer for repair. DO NOT attempt to perform

this process yourself as engine damage may result from

contaminants involved in the cleaning process for the port.

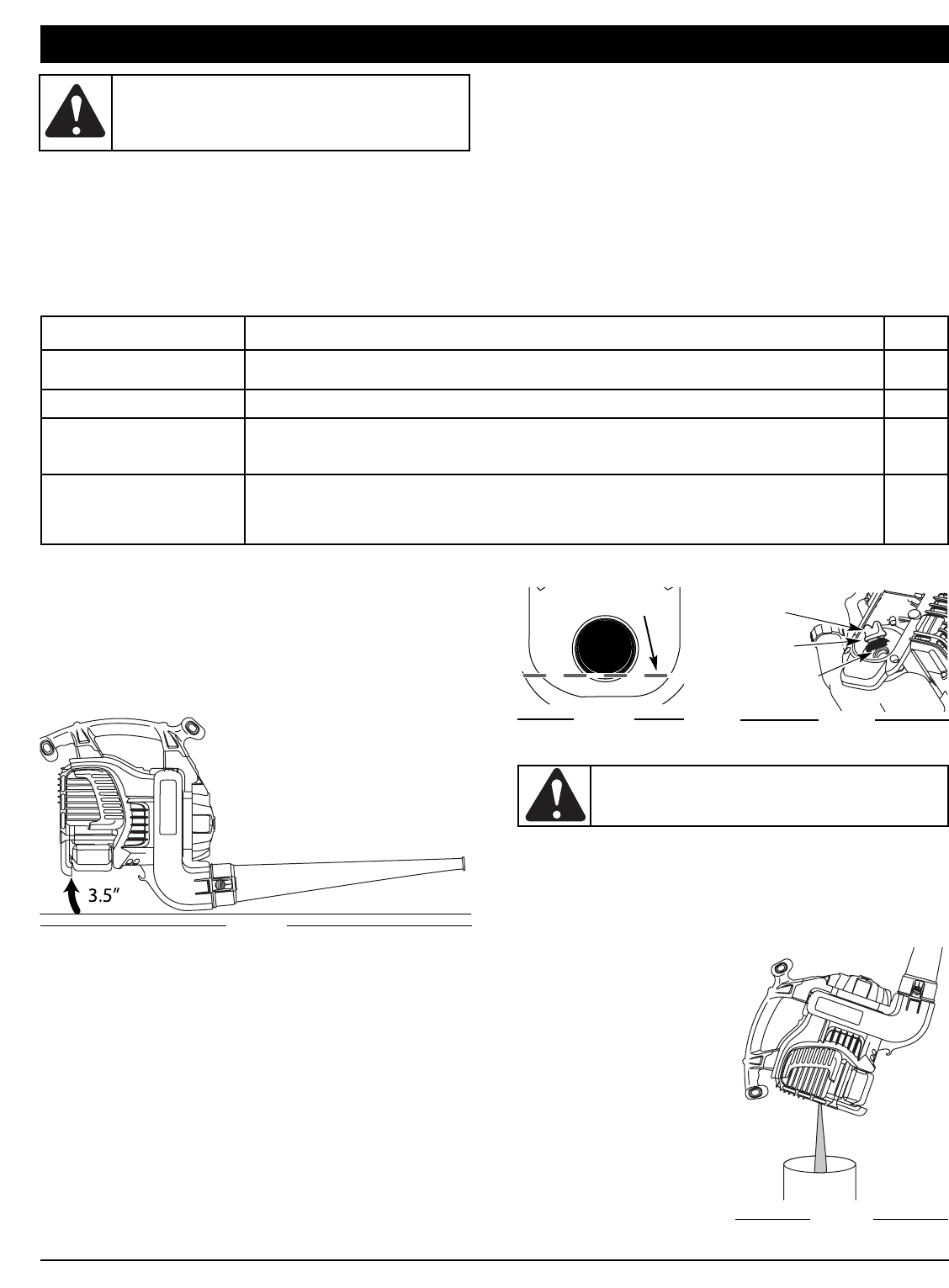

CHANGING THE OIL

For a new engine, change the oil after the first 10 hours of

operation. Change the oil while the engine is still warm. The oil

will flow freely and carry away more impurities.

1. Unplug spark plug boot to prevent accidental starting.

2. Remove the oil fill plug.

3. Pour the oil out of the oil

fill hole and into a

container by tipping the

unit to a vertical position

(Fig. 24). Allow ample

time for complete

drainage.

4. Wipe up any oil residue

on the unit and clean up

any oil that may have

spilled. Dispose of the

oil according to Federal,

State and local

regulations.

5. Refill the crankcase with

3.04 fluid ounce (90 ml)

or 3/8 cup of SAE 30 SF,

SG, SH oil.

WARNING: Wear gloves to prevent injury when

handling unit.

Fig. 24

Fig. 21