WARNING: Beforeinspecting, cleaningor servicing the machine,shut off engine,wait for all

moving partsto come to a complete stop, disconnect spark plug wireand move wire awayfrom

spark plug. Failureto follow these instructions canresult in serious personalinjury or property

damage.

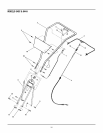

4. Thegear oil level iscorrect if thegear oil

isapproximately halfway upthe sideofthe

main driveshaft.

5. Ifthe gearoil levelislow, addgear oil as

described next.If the gearoil levelisokay,

securely replacethe oil fill plug.

IMPORTANT:Donot operatethe tiller ifthe

gear oil level is low. Doingso will result in

severedamageto the transmission com-

ponents.

Figure5-2: Removeoil fill p/ug (,4)to check

gear oil level and toaddgear oil. Remove

fourcoverscrews(B) to draingear oil.

6. If adding only a few ounces of gear oil,

useAPIrated GL-4or GL-5gearoil having

a viscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an emptytrans-

mission, useonly GL-4gear oil having a

viscosity of SAE85W-140 or SAE140.

IMPORTANT:Do not useautomatic trans-

mission fluid or motor oil inthe transmis-

sion.

7. Whilecheckingfrequently to avoidover-

filling, slowly add gear oil into the oil fill

hole until it reachesthe halfwaypoint on

the driveshaft.

8. Securely replacethe oil fill plug.

B. ToDrain theTransmissionGearOil:

Thetransmission gear oil does notneedto

bechanged unless it hasbeencontaminat-

ed with dirt, sand or metal particles.

1. Draingasolinefrom thefuel tank or run

the engine until thefuel tank is empty.See

"DANGER"statement below.

WARNING: Gasolineis

highlyflammableandits vapors

areexplosive. Followthese

safety practicesto prevent

personalinjury or property

damagefrom fire or explosion.

Allow the engine and muffler to cool

for at least two minutesbeforedrain-

ingtheUller's gasolinetank.

Do not allow open flames, sparks,

matchesorsmokingin thearea.

Wipe away spills and pushtiller away

fromspilled fuel.

Use only an approvedfuel container

and store it safelyout of the reach of

children.

Do notstoregasoline in an area where

its vaporscould reach an openflame

orspark, orwhere ignitionsourcesare

present(suchas hot water and space

heaters, furnaces, clothes dryers,

stoves,electric motors,etc.)

2. Drainthe oil from the engine.

3. Removefour screws (B,Figure5-2)and

removetransmissioncoverandgasket.

4. Removethe left-side wheel.

5. Tilt the left-side wheelshaft into a drain

panand allowthe gearoil to drainthrough

the top of thetransmission.

6. Reinstallthe wheel.

7. Install a newgasket (do not reuseold

gasket)and reinstall the transmission cov-

er.

8. Refill the transmission using GL-4gear

oil (SAE85W-140 or SAE140).

9. Refill the enginewith motor oil and re-

plenishthe fuel tank with gasoline.

BOLOTINES

Thebolo tines will wear with useand

should be inspectedatthe beginning of

eachtilling seasonand after every30 oper-

ating hours. Thetines can be replacedei-

ther individually or as a completeset. See

the Parts List pagesfor tine identification

and part numbers.

A. Tine Inspection:

With use,the tines will becomeshorter,

narrower and pointed. Badlyworn tines

will result in a loss of tilling depth, and re-

ducedeffectivenesswhen chopping up

andturning under organic matter.

B. Removin_nstalling a Single Tine:

1. With the engine shut off andthe spark

plug wire disconnected,remove thetwo

screws (A,Figure5-3)and nuts (B)that at-

tachasingletineto atine holder. If needed,

usepenetrating oil on the nuts.

2. When installing a singletine, besureto

position it so that its cutting edge (sharp)

will enter thesoil first asthe tiller moves

forward.

C. Removin_nstalling a TineAssembly:

1. Atine assemblyconsists of eighttines

mounted on atine holder.

2. If removing both tine assemblies,mark

them "left" and "right" beforeremoval. Re-

move the screw (C, Figure5-3) and lock-

nut (D)that securethetine assemblyto the

tineshaft. If necessary,usea rubber mallet

to tapthe tine assembly outward off the

shaft.

3. Beforereinstallingthetine assembly,in-

spectthe tineshaft for rust, roughspots or

burrs. Lightly file or sand, as needed.Ap-

ply a thin coat of greaseto the shaft.

4. Install eachtine assemblyso that the

cutting (sharp) edge of thetines wifl enter

thesoil first whenthetiflermovesforward.

Securethe tine assemblyto the tine shaft

usingthe screwand Iocknut

18