SECTION5: MAINTENANCE

WARNING: Before

inspecting, cleaningor servicing

the machine,shut off engine,

wait for all moving parts to come

to acompletestop, disconnect

spark plug wire and movewire

awayfrom spark plug. Remove

ignition keyon electricstart

models.

Failureto follow these

instructions can result in serious

personalinjury or property

damage.

MAINTENANCESCHEDULE

PROCEDURE

Checkmotor oil level

Cleanengine

Checkdrive belttension

Checknuts and bolts

Changemotor oil

Lubricatetiller

Serviceengine air cleaner system

Checkgearoil levelin transmission

Checktines for wear

Checkair pressure in tires

(if unit haspneumatic tires)

Servicespark plug

NOTES

NOTES

2,3

2,7

1,4

1,4

4,6,9

4

7

1,5

5

5

1 Checkafter first 2 hours of break-in operation.

2 Beforeeachuse.

3 Every5 operating hours.

4 Every 10operating hours.

5 Every30 operating hours,

6 Changemore frequently in dusty conditions.

7 - SeeEngineOwner'sManual forservice

recommendations.

8 - Whichever time interval occurs firsL

g - Changeafter first 2 hours of break-in

TILLER LUBRICATION

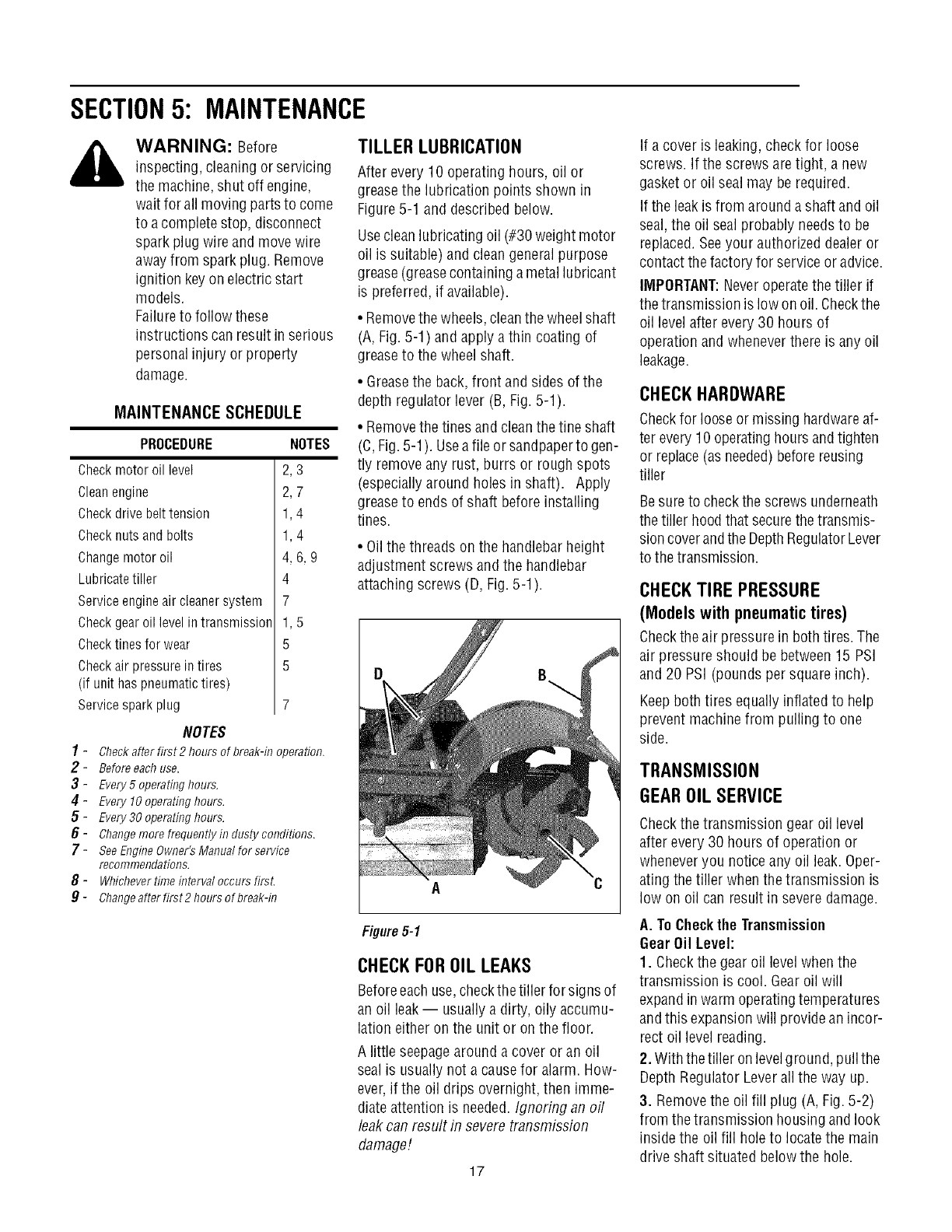

After every 10 operating hours, oil or

greasethe lubrication points shown in

Figure5-1 and described below.

Usecleanlubricating oil (#30weight motor

oil is suitable) and cleangeneralpurpose

grease(greasecontaining a metallubricant

is preferred, if available).

• Removethe wheels,cleanthe wheelshaft

(A,Fig. 5-1) and apply a thin coating of

greaseto the wheelshaft.

• Greasethe back,front and sides of the

depthregulator lever (B, Fig.5-1).

• Removethe tines andclean thetine shaft

(C,Fig.5-1). Usea file or sandpaperto gen-

tly removeany rust, burrs or rough spots

(especiallyaround holes in shaft). Apply

greaseto ends of shaft beforeinstalling

tines.

• Oil thethreads on the handlebar height

adjustment screws and the handlebar

attaching screws (D, Fig.5-1).

Figure5-1

CHECKFOR OIL LEAKS

Beforeeachuse,checkthe tiller for signs of

an oil leak-- usually a dirty, oily accumu-

lation eitheron the unit or on the floor.

A little seepagearound a cover or an oil

sealis usually not a causefor alarm. How-

ever,if the oil drips overnight, then imme-

diateattention is needed.Ignoring an oil

leakcanresult in severetransmission

damage!

17

If acover is leaking,check for loose

screws. If the screws aretight, a new

gasket or oil seal may be required.

If the leakisfrom around a shaftand oil

seal, the oil sealprobably needsto be

replaced.Seeyour authorized dealeror

contact the factory for serviceor advice.

IMPORTANT:Neveroperatethe tiller if

thetransmission islow on oil.Checkthe

oil levelafter every 30 hours of

operationand wheneverthere is anyoil

leakage.

CHECKHARDWARE

Checkfor loose or missing hardwareaf-

ter every 10 operatinghours andtighten

or replace(asneeded)before reusing

tiller

Besure to checkthe screws underneath

thetiller hoodthat securethe transmis-

sioncoverandtheDepthRegulatorLever

to thetransmission.

CHECKTIRE PRESSURE

(Models with pneumatictires)

Checkthe air pressurein both tires. The

air pressure should be between 15 PSi

and 20 PSi (pounds per squareinch).

Keepboth tires equally inflated to help

prevent machinefrom pulling to one

side.

TRANSMISSION

GEAROIL SERVICE

Checkthe transmission gear oil level

after every 30 hours of operationor

wheneveryou notice anyoil leak.Oper-

ating thetiller when thetransmission is

low on oil can result in severedamage.

A. To Checkthe Transmission

GearOil Level:

1. Checkthe gear oil levelwhenthe

transmission is cool. Gearoil will

expandin warm operatingtemperatures

and this expansionwill providean incor-

rect oil level reading.

2. With thetiller onlevelground, pullthe

Depth Regulator Leverall the way up.

3. Removethe oil fill plug (A, Fig. 5-2)

from thetransmission housingandlook

insidethe oil fill hole to locatethe main

driveshaft situated belowthe hole.