17

• Insert the hex shaft through the sprocket and the

spacer. Make certain that the chain engages both

the large and the small sprocket.

NOTE: If the sprocket fell from the snow thrower while

removing the hex shaft, place the sprocket on the hex

shaft. Position the hex hub of the sprocket toward the

friction wheel when sliding the sprocket on to the hex

shaft. See Figure 23.

• Secure with the bell washer and hex bolt removed

earlier.

• Secure the frame cover with six self-tapping

screws. Put the snow thrower down to its normal

operating position.

NOTE: If you placed plastic film under the gas cap, be

certain to remove it.

Off-season Storage

WARNING: Never store engine with fuel in

tank indoors or in poorly ventilated areas,

where fuel fumes may reach an open flame,

spark or pilot light as on a furnace, water

heater, clothes dryer or other gas appliance.

• If unit is to be stored over 30 days, prepare engine

for storage as instructed in the engine manual.

• Remove all debris from the exterior of equipment.

• Follow lubrication recommendations on page 13.

• Always store the snow thrower in a clean, dry area.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust proof the equipment. Using a light oil or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

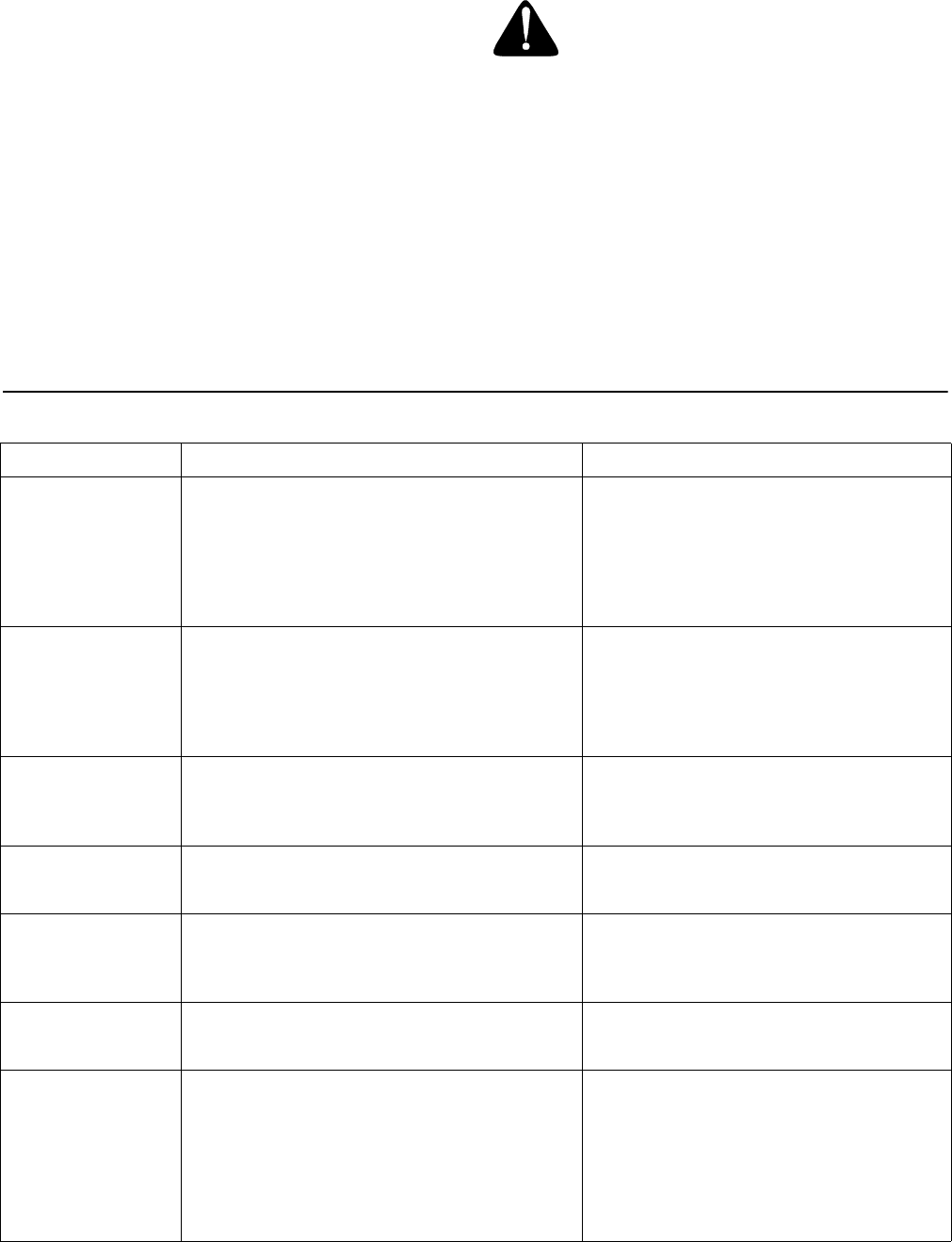

SECTION 8: TROUBLESHOOTING

NOTE: For repairs beyond the minor adjustments listed above, contact an authorized Troy-Bilt service dealer.

Problem Cause Remedy

Engine fails to start. 1. Fuel tank empty, or stale fuel.

2. Blocked fuel line.

3. Choke not in ON position

4. Faulty spark plug.

5. Safety key not in ignition switch on engine.

6. Spark plug wire disconnected.

7. Primer button not being used properly.

1. Fill tank with fresh gasoline.

2. Clean the fuel line.

3. Move switch to ON position

4. Clean, adjust gap or replace.

5. Insert the key fully into the switch.

6. Connect spark plug wire.

7. Refer to the engine manual.

Engine runs erratic. 1. Unit running on CHOKE.

2. Blocked fuel line or stale fuel.

3. Water or dirt in fuel system.

4. Carburetor out of adjustment.

1. Move choke lever to OFF position.

2. Clean fuel line and fill tank with clean, fresh

gasoline.

3. Drain fuel tank and carburetor. Refill with

fresh fuel.

4. Refer to the engine manual.

Loss of power. 1. Spark plug wire loose.

2. Gas cap vent hole plugged.

3. Exhaust port plugged.

1. Connect and tighten spark plug wire.

2. Remove ice and snow from gas cap. Be

certain vent hole is clear.

3. Refer to the engine manual.

Engine overheats. 1. Carburetor not adjusted properly. 1. Refer to the engine manual or have the

carburetor adjusted by an authorized

engine service dealer.

Excessive vibration. 1. Loose parts or damaged auger. 1. Stop engine immediately and disconnect

spark plug wire. Tighten all bolts and nuts. If

vibration continues, have unit serviced by

an authorized service dealer.

Unit fails

to propel itself.

1. Traction control cable in need of adjustment.

2. Drive belt loose or damaged.

1. Adjust traction control cable. Refer to

Adjustments.

2. Replace drive belt.

Unit fails

to discharge snow.

1. Discharge chute clogged.

2. Foreign object lodged in auger.

3. Auger control cable in need of adjustment.

4. Auger belt loose or damaged.

5. Shear bolt(s) sheared.

1. Stop engine immediately and disconnect

spark plug wire. Clean discharge chute and

inside of auger housing.

2. Stop engine immediately and disconnect

spark plug wire. Remove object from auger.

3. Refer to Auger Control Test on Page 9.

4. Refer to Adjustments.

5. Replace shear bolt(s).