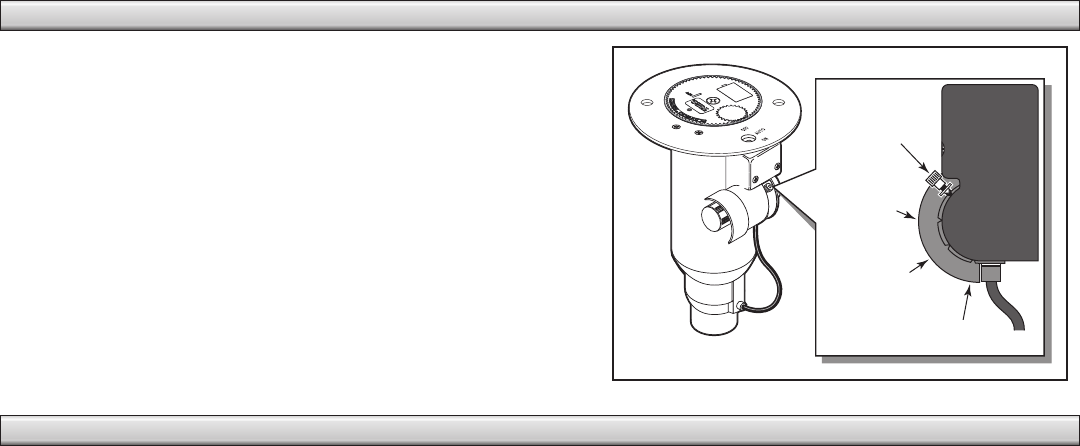

Pilot Valve Operation (Electric Models Only)

The pilot valve controls the operation of the main valve located

in the base of the sprinkler body. The main valve is operated by

the release of water metered through the pilot valve when it is

activated either manually at the sprinkler or by the irrigation system

controller.

Another important function of the pilot valve is to regulate the

water pressure to the sprinkler nozzle. Pressure regulation

compensates for large variations within the system and maintains

a constant pressure for optimum sprinkler operation. The pilot

valve is factory set to regulate one of four pressure levels: 50 psi

(3.5 bar), 65 psi (4.6 bar), 80 psi (5.6 bar) or 100 PSI (7.0 bar).

Change the pilot valve operating pressure by loosening the thumb

screw that secures the selector lever. Position the selector lever to

the desired operating pressure and hand-tighten the nut.

See Figure 5.

Troubleshooting

Possible equipment failures with causes and corrective action are listed below.

Sprinkler won’t rotate

– Debris wedged between stator and turbine

• Remove obstruction

– Drive assembly defective

• Replace drive assembly

– Nozzle base assembly defective

• Replace riser assembly

Head sticks up

– Dirt in riser assembly

• Flush out. (See Flushing Sprinklers)

– Damaged or missing return spring

• Replace

– Damaged riser

• Replace

Poor distribution pattern

– Nozzle plugged with debris

• Clean or replace nozzle

– Nozzle orifice damaged

• Replace nozzle

– Low operating pressure

• Determine why system overloaded and correct

Valve won’t close (Electric)

– Continuous 24 VAC to sprinkler

• Check controller for voltage source

– Debris in Pilot Valve

• Disassemble and remove all debris

– Leak in pilot valve assembly

• Replace pilot valve assembly

– Plugged supply screen on piston

• Clean or replace screen

– Manual control selector on pilot valve assembly turned to “ON” position

• Turn to “AUTO” position

– Plunger movement restricted

• Inspect and clean or replace

– Valve cylinder misaligned with sprinkler body communication tube

• Remove valve assembly and install correctly

– Foreign object keeping valve from seating

• Remove, clean and check valve for damage. Replace if necessary

– Damaged piston seal or piston assembly

• Replace valve assembly

100 PSI

(7.0 kg/cm

2

)

80 PSI

(5.6 kg/cm

2

)

65 PSI

(4.6 kg/cm

2

)

50 PSI (3.5 kg/cm

2

)

Figure 5