Reelmaster 7000 Hydraulic SystemPage 4 -- 21

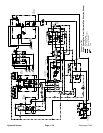

Mow Circuit

Hydraulic flow for the mow circuit is supplied by two (2)

sections of the gear pump (P1 andP2). Gear pump sec-

tion P1 supplies hydraulic flow to cutting units 1, 4 and

5 (front cutting units), while gear pump section P2

supplies cutting units 2 and 3 (rear cutting units).

A single mow control manifold is used to control flow

from the two (2) pump sections. The manifold includes

cartridge valves for control of each of the two (2) pump

circuits. Each manifold circuit is equipped with a s ole-

noidcontrolled,proportionalvalve( SP1 andSP2),alog-

ic cartridge (LC1 and LC2) and a circuit relief cartridge

(RV1 and RV2).

Allcuttingreelmotorsareequippedwithcrossoverrelief

valves to prevent hydraulic component damage in case

a cutting reel should stall.

The TEC controller uses inputs from v arious machine

switches to determinewhen solenoid proportional valve

(SP1 and SP2) are to be energized. The controller also

provides a slight delay in activation of the rear cutting

units.

NOTE: When the mow speed limiter is in the transport

(2WD) position, the mow circuit c annot be engaged.

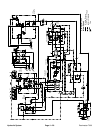

PTO Disengaged (Fig. 15)

When the PTO switch is OFF (or if the cutting units are

raised), themanifold proportionalvalves (SP1 andSP2)

are not energized, which causes a pressure increase

that shiftsthe logic cartridges (LC1and LC2). Thepump

flow is routed through the shifted logic cartridge and out

manifold portT1. Returnoil from themanifold isdirected

to the oil cooler and oil filter.

PTO Engaged

When the PTO switch is turned ON with the cutting units

lowered, the manifold proportional valves (SP1 and

SP2) are energized with outputs from the TEC--5002

controller.Theenergizedvalves shifttodirectpump flow

toward the cutting unit motors. Flow from the valves is

proportional to current applied to the valve coil by the

TEC controller. The settingof thereel speed controlpro-

vides the input for the TEC controller to allow the ap-

propriate current to the valve coil.

Flow through the speed control valve is pressure com-

pensated by the logic cartridge valves (LC1 and LC2).

The logic c artridge valve maintains a pressure of 110

PSI (7.6 bar) across the proportional valve. Any excess

flow is returned to the hydraulic reservoir.

Maximum mow circuit pressure is limited at each mow

manifold circuit by the reliefvalve (RV1 or RV2). The re-

lief valve pressure is 3000 PSI (207 bar).

When the reels are shut off, the over--running inertia

load of the reels keeps driving the reel motors and can

turn them into pumps. The check valves (CV1 and CV2)

in the mow control manifold will open to keep the reel

motor circuit full of oil so the motors will not cavitate.

Backlap

When either ofthe mow controlmanifold backlap valves

are rotated to the backlap (R) position, pump flow to the

cutting unit motors is reversed. This change in flow di-

rection reverses the rotation of the front or rear cutting

reel motors allowing the backlap operation.

Figure 14

CUTTING UNIT LOCATIONS

#4 #1 #5

#3#2

Figure 15

P1 T2 T1 P2

RV2

SP1

SP2

LC2

LC1

RV1

M5

CV1

M1M4

OR1

OR2

CV2

M3M2

MV1

MV2

M3M4M1 M2

MOW

MANIFOLD

CONTROL

FROMGEAR

PUMPP1

FROMGEAR

PUMPP2

Hydraulic

System