Rotary Mowers 5

Toro University Technical Training

Power transfer from the engine to the blades is

typically done by way of belts and transfer shafts.

Belt drives typically transfer a high percentage of

the available horsepower to the blade and generally

produce much less noise than hydraulic drive

systems.

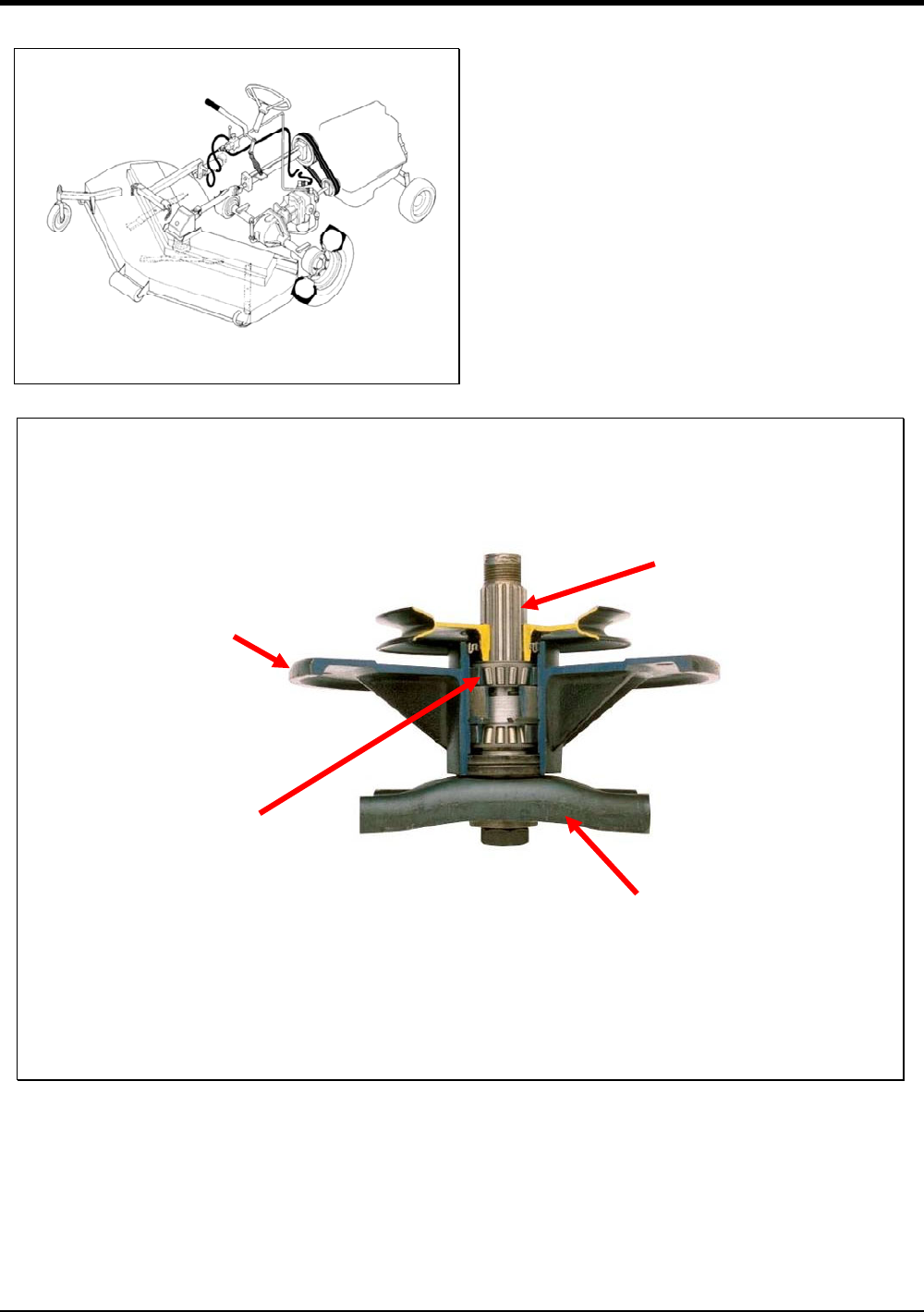

Blade spindle assembly

Large Diameter

Ductile Cast Iron

Spindle Support

Ductile cast iron,

stronger than

aluminum or

regular cast iron

Timken

®

Tapered

Roller Bearings

Support spindle

shaft better than

ball bearings

50% more load

carrying capacity

than ball bearings

Solid Cold Finished

Steel Spindle Shaft

Large diameter shaft is

resistant to torsion and

bending failure

Blade Retainer &

Anti-Scalp Cup

Eliminates blade

slippage and protects

turf from damage

The deck spindles usually run at approximately 2000 to 2500 RPM. They feature tapered roller bearing for

impact resistance and durability. The bearings can be greased, and if done properly can ensure long life

while also purging contaminates from the assembly.