Rotary Mowers 21

Toro University Technical Training

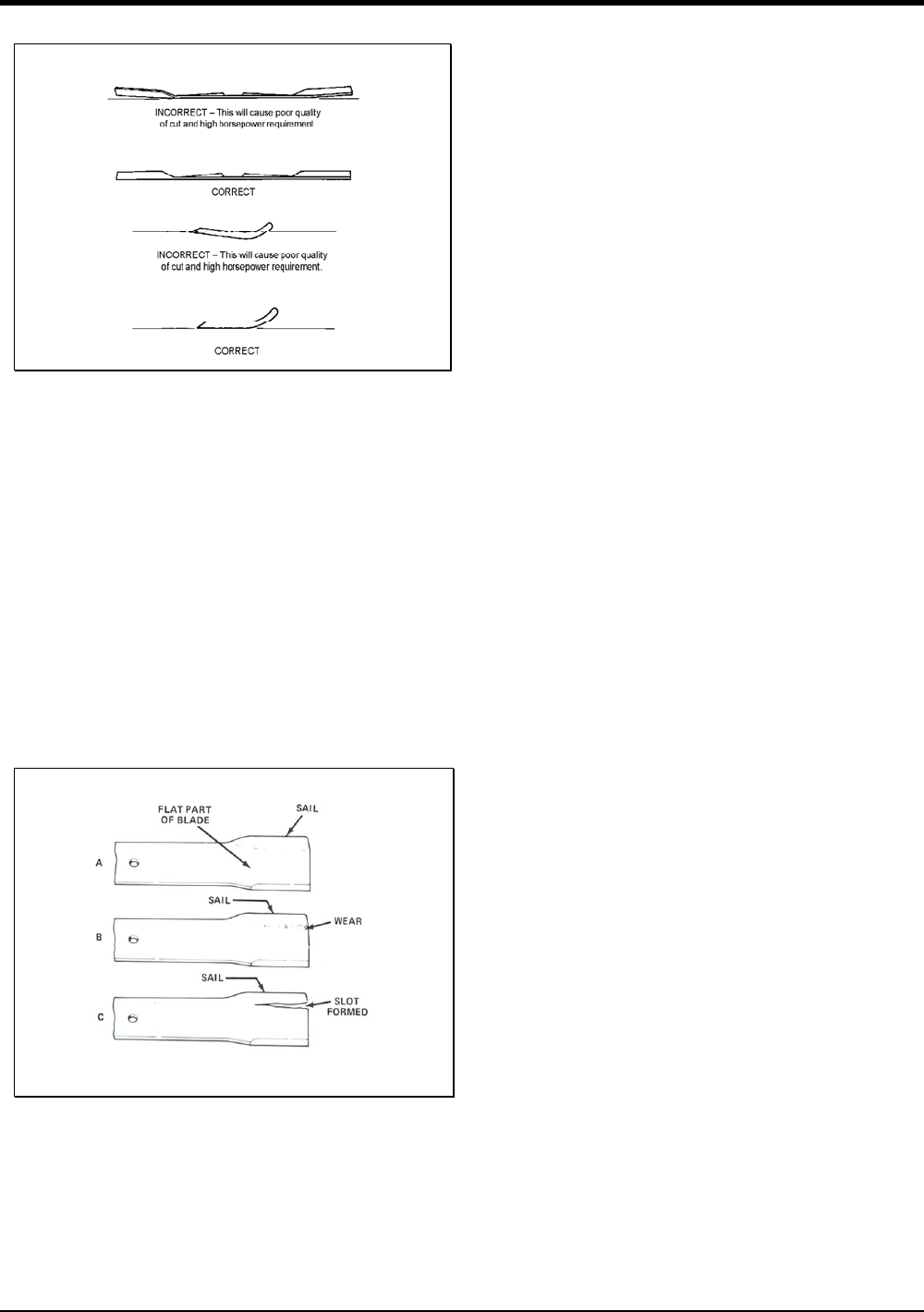

The most common causes for rotary mowers not

giving a good quality of cut are due to dull cutting

edges and/or bent blades.

Caution: Check cutter blade daily or before mower is

used or stored and whenever mower is serviced. If

bolt holding blade is loose, tighten it before using

mower.

If the blade is bent, the blade should be replaced. A

bent blade will cause two problems. The most

noticeable problem a increase in horsepower that is

required to operate the mower. This is caused by the

fact that when the grass is cut the at the outer edge

of the blade it is higher then the next area of the

blade. The grass is then cut again and again until

the height is the same as the lowest cutting edge.

The same grass blade could be cut several times.

This can take a considerable amount of power to

repeatedly cut the same grass blade.

The other problem is that this will adversely affect the

quality of cut. In this scenario, a very small amount of

grass is cut from the grass blade frequently. This

can cause the top of the grass blade to fray and it

leaves the grass blade with a unhealthy cut edge.

This will usually show up as a brown die-back from

the top of the grass blade.

In this situation the blade should be replaced.

NEVER straighten a Bent Blade as this could

weaken the blade and cause the blade to break.

Carefully examine cutting ends of blade, especially

where the flat and sail parts of the blade meet. When

mowing in dry or sandy areas, sand and abrasive

material can wear away the metal that joins the sail

and flat part of the blade. For safety, it is important

that when any wear is noticed, the blade must be

replaced. If the condition is not corrected and wear

continues, a slot will form. Eventually a piece of the

sail may break off and be thrown from under the

housing, possibly resulting in serious injury to

yourself or bystander.