18 Rotary Mowers

Toro University Technical Training

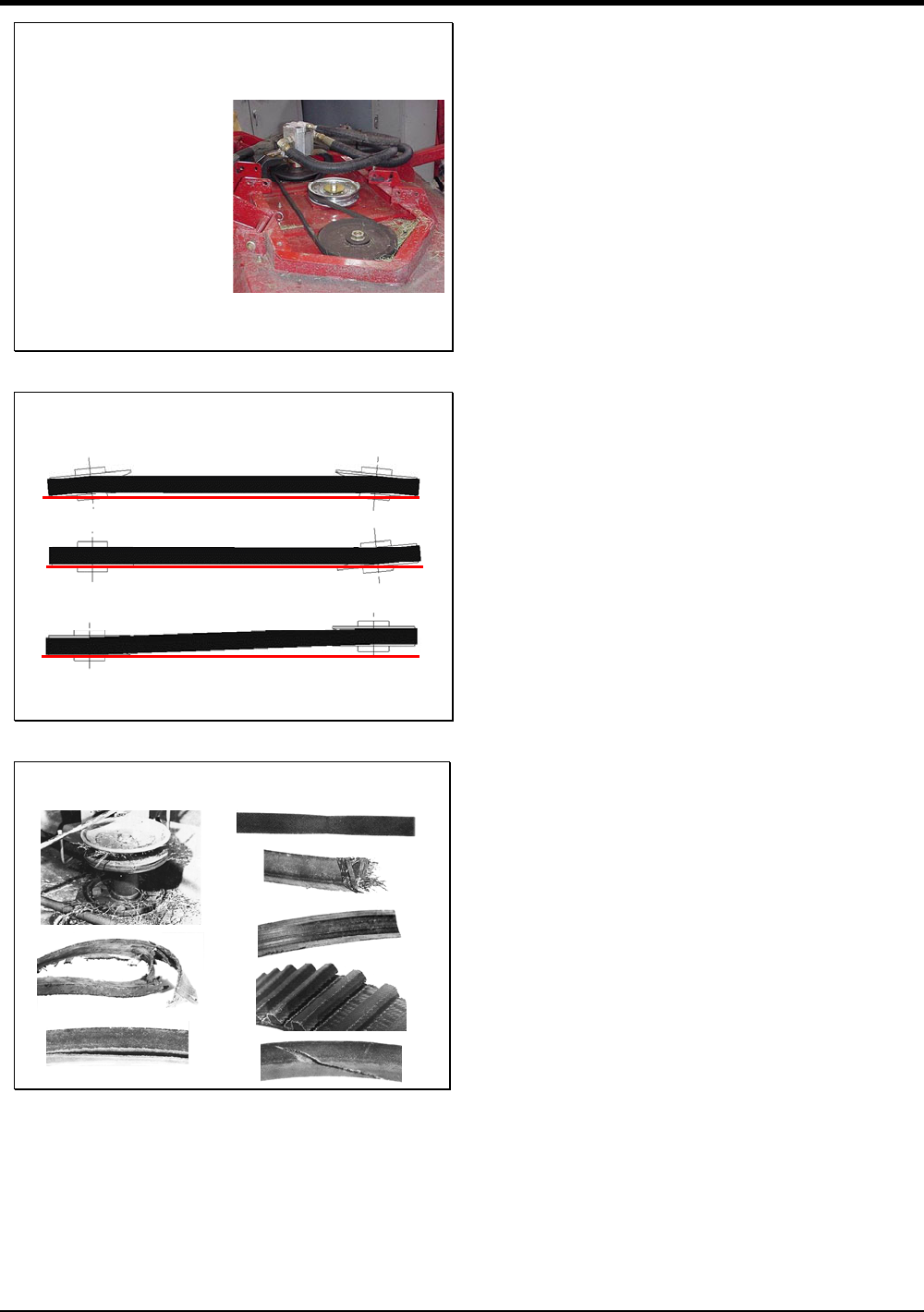

Inspecting drive belts and pulleys

• Oil or grease

contamination

•Debris in pulleys

• Damaged or rusted

pulleys

• Proper installation

and tensioning

Periodically inspect drive belts and pulleys. A good

time to do this is after cleaning the machine.

• Oil or grease contamination

• Debris in pulleys

• Damaged or rusted pulleys

• Proper installation and tensioning

Drive belt failures

The most common causes of belt failures:

• Alignment

• Contamination

• Loading

• Installation Issues

Alignment refers to the alignment of one pulley in

relationship to the other. If this alignment is not

correct the belt may show excessive wear to one of

both sides of the belt. Some of the cords in the belt

may be broken or the belt may actually flip over.

Drive belt failures

Contamination refers to some other substance

coming in contact with the belt. This may be oil,

grease or other some other foreign object.

Loading refers to excessive loads or shock loading

the drive system.

The last one is installation issues. The belt is

actually damaged during installation.

By inspecting the failed belt the user can get a good

idea as to the cause of the belt failure and can

correct it when the new belt is installed.