9-1

9 CHECK AND ADJUSTMENT

9 CHECK AND ADJUSTMENT

9.1 Checking and Adjusting of Instrument Constant

Normally, the instrument constant does not have discrepancy. It is recommended you measure and

compare with an accurately measured distance at a location where the precision is specifically

monitored on a consistent basis. If such a location is not available, establish your own base line over

20m (when purchasing the instrument) and compare with the data measured with newly purchased

instrument.

In both cases note that the setup displacement of the instrument position over the point, the prism,

baseline precision, poor collimation, atmospheric correction, and correction for refraction and earth

curvature determine the inspection precision. Please keep in mind these points.

Also, when providing a base line in a building, please note that the difference in temperature greatly

changes the length measured in the building.

If a difference of 5mm or over is the result from the comparative measurement, the following procedure

as shown below could be used to change the instrument constant.

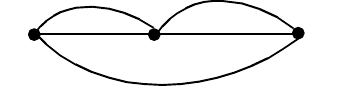

1) Provide point C on a straight line, connecting straight line AB which is almost horizontal and about

100m long, and measure straight lines AB, AC and BC.

2) Obtain the instrument constant by repeating 1) above several times.

Instrument constant=AC+BC-AB

3) When there is error between written instrument constant value and calculated value, review the

Section 9.7 “How to Set the Instrument Constant Value” procedure.

4) Once again, measure at a calibrated baseline and compare with the instrument base line the

length.

5) If using above procedure and no difference is found from the instrument constant at the factory or a

difference of over 5mm is found, contact TOPCON or your TOPCON dealer.

A

C

B