Operation Section 4-9

OPERATION

RBF-19C 07/04

© 2004 Alamo Group Inc.

5. CONNECTING ATTACHING HEAD TO THE BOOM

The rotor unit can now be fitted to the end of the arms.

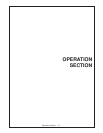

The illustration shows the Rhino 1948 cowl bracket.

Start the tractor engine and raise the second arm so

that the mower head clamp is approximately 300mm

(18 in.) clear of the ground. Place the mower head

directly in front of the second arm. Level up mower

head with wood packing. Remove clamp bracket (A)

from the end of arms. Adjust position of the arms until

the mower head clamp is lined up with the clamping

bar on top of the rotor unit in the desired position along

the bar. Replace clamp bracket (A) and nut and

washers (B). Tighten fully. Note: Additional support

may be needed at the end of the Boom to aid in

installation.

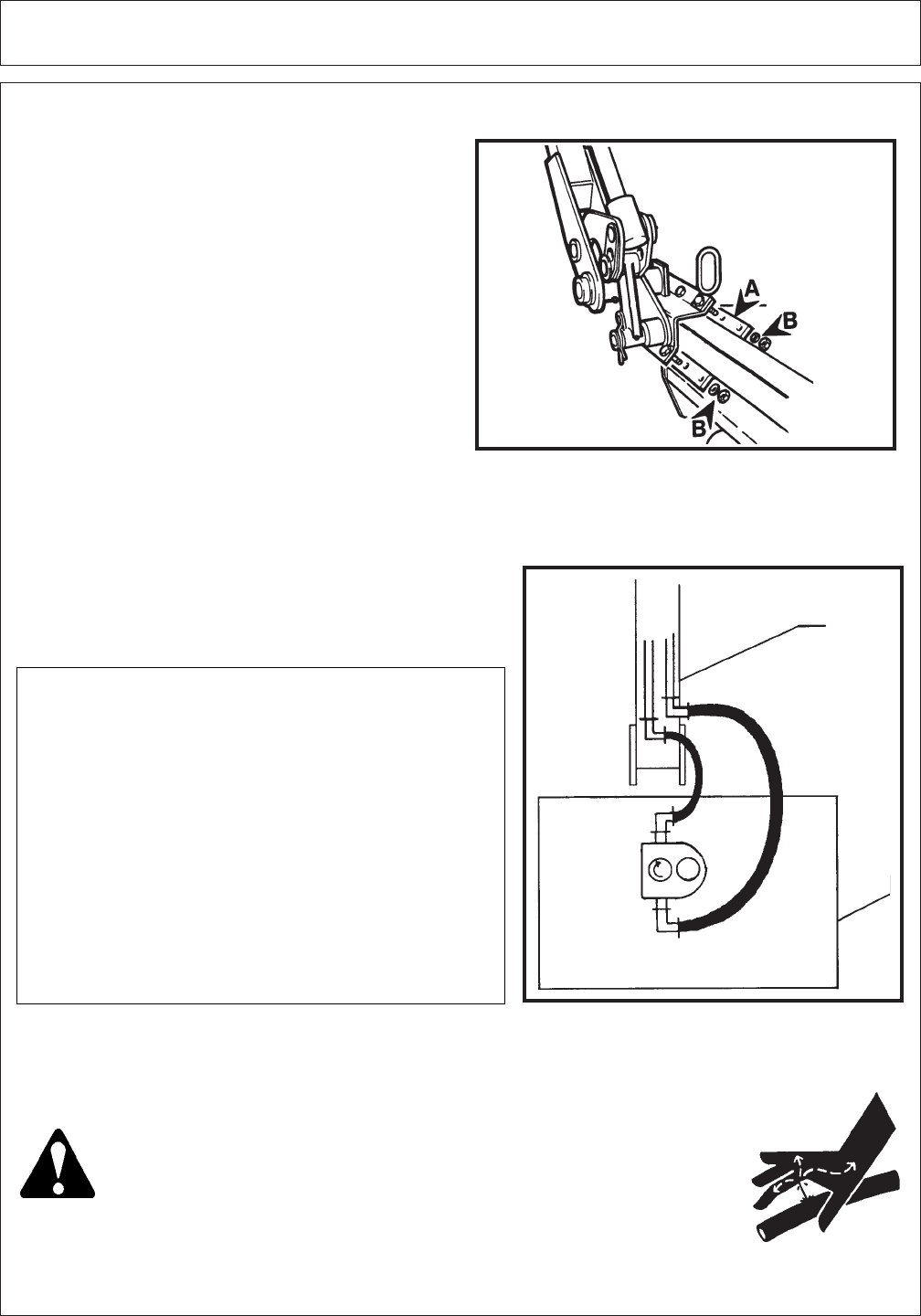

5.2 Connecting Mower Head Hydraulics

Attach the 1" hoses, from the articulating arm to the

hydraulic motor on the head. Use recommended hose

end torque values in chart below.

* Straight threads do not always seal better when higher

torques are used. Too much torque causes distortion and

may lead to leakage.

VALUE*

(FT.LBS.)

12

19

38

54

75

100

133

167

233

TORQUE

(IN.LBS.)

140

230

450

650

900

1200

1600

2000

2800

NOMINAL

SIZE (IN.)

1/4

3/8

1/2

5/8

3/4

1

1-1/4

1-1/2

2

DASH

SIZE

-4

-6

-8

-10

-12

-16

-20

-24

-32

DANGER! Do not operate this Equipment with hydraulic oil leaking. Oil is

expensive and leaking oil could present a hazard. Do not check for

leaks with your hand! Use a piece of heavy paper or cardboard. High-

pressure oil streams from breaks in the line could penetrate the skin

and cause tissue damage including gangrene. If oil does penetrate the

skin, have the injury treated immediately by a physician. (SG-15)

Boom

End

Head

Return

Pressure