Side & Rear flail Maintenance Section 4-20

MAINTENANCE

GREASING THE IDLER TENSION ARMS

Locate the access holes and grease zerks in the belt shields of the side and rear

flails. Normal conditions require one pump daily or every 8 hours of service with

multi purpose grease.

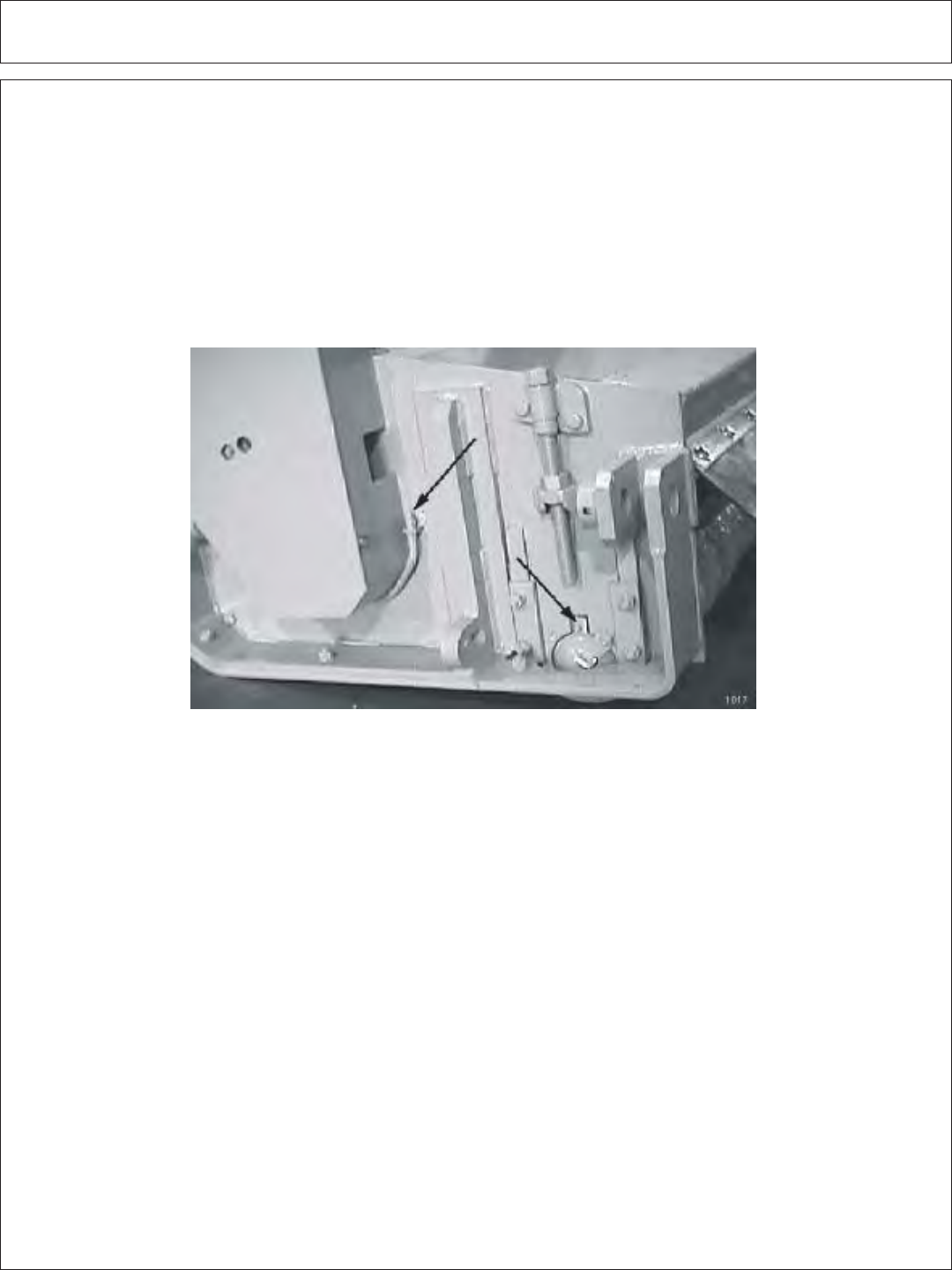

IDLER TENSIONING

Locate the idler tensioning rod for each flail. Loosen the locking nut. Turn the

adjusting nut until the washer in between the spring and nuts is flush with the spring

housing or guide. Tighten locking nut securely. For standard cut on side flail adjust

until the spring washer is flush with the top of the spring housing, as shown below.

Use this same method to adjust hydraulically driven rear flails.

GREASING GROUND ROLLER SHAFT – FLAIL

Locate grease zerks on each end of roller tube at lower rear of head. Normal

conditions require one or two pump in each bearing, using Lithium-Complex

Extreme Pressure grease conforming to NLGI2-ISO 320 specifications. This is to

be done with a standard grease gun daily or at 8 hour intervals. CAUTION:

Over greasing may cause premature seal failure.