12 ► HP TWIN8 User Manual

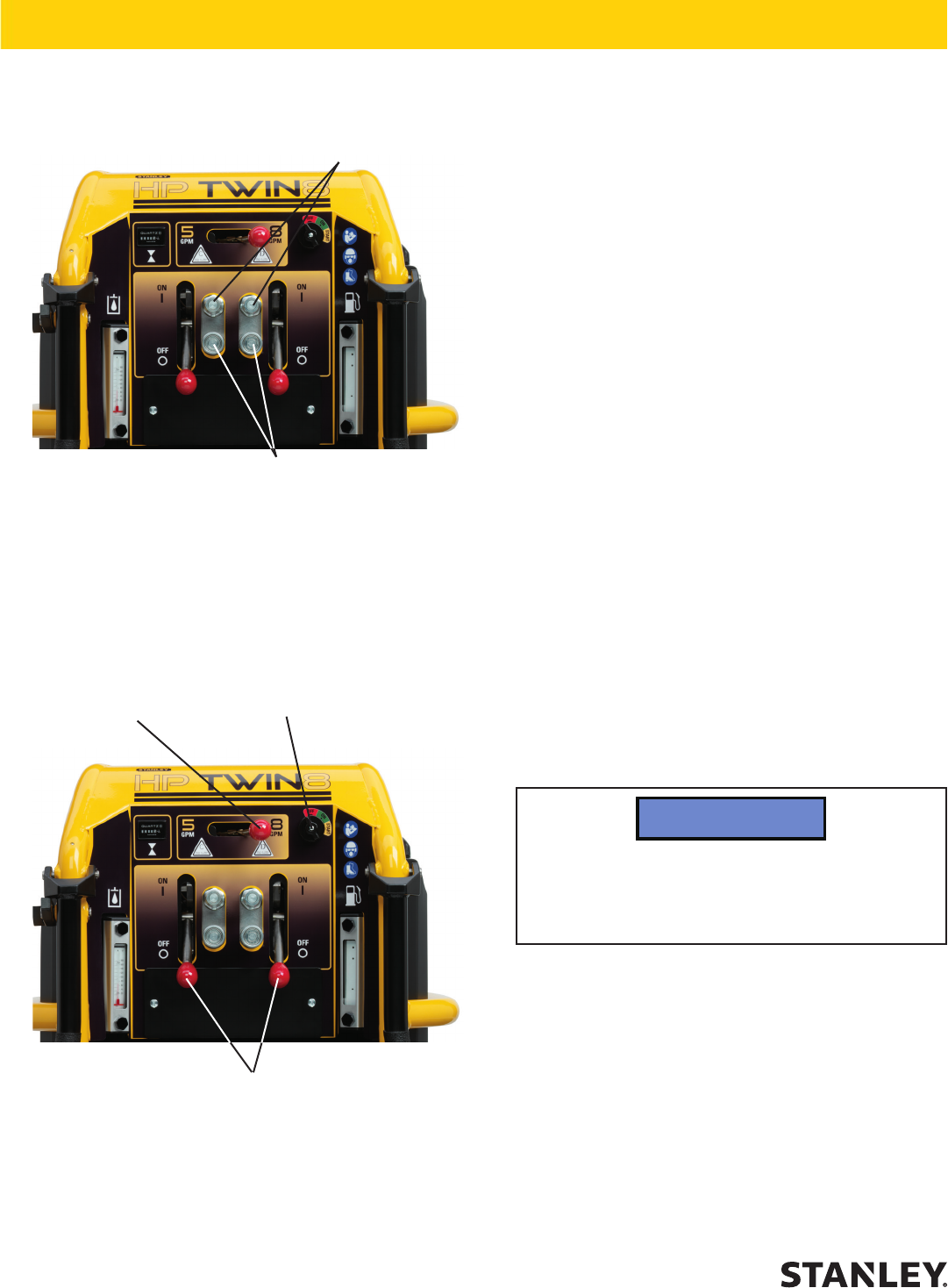

COUPLERS (HOSE CONNECTIONS)

Facing the control panel, the top (2) male couplers are

the PRESSURE FLUID OUT ttings. The bottom (2)

female quick disconnect couplers are the RETURN

FLUID IN. Their are two independent circuits, one on

the left and one on the right, each controlled by the

adjacent lever.

CONTROLS (DUAL CIRCUIT)

When the throttle control lever is in the far left position,

it will produce 5 GPM to both circuits at the same time

and with the lever in the far right position will produce 8

GPM to both circuits. This allows two tools that can run

simultaneously at 5 or 8 GPM.

The ow control levers when turned “ON” (up position)

turns on ow to the tool or tools depending on if you

are using one or both circuits.

STARTUP

1. Before starting the engine check the engine oil and

hydraulic uid level.

2. Check to make sure the ow Control levers are in

the OFF position (Down), the power unit will not

start if the levers are in the “UP” position (ON).

3. Connect hoses and the tool as described on page

9.

4. It is not necessary to choke the engine, it is

equipped with a “Electronic Fuel Management

System” that does not have a manual choke.

5. Set the throttle control lever to the left (5-GPM)

setting. Once the unit starts and is warmed-up the

lever can be moved to the 8-GPM setting if desired.

6. Turn the Ignition Switch to the START position.

After the engine starts, release the switch.

7. Allow the engine to warm up.

8. Turn on the ow to the tool by lifting the “Flow

Control Levers” up into the on position, lift both

levers if running two circuits (two Tools).

SHUTDOWN

1. Ensure the ow control levers are in the OFF

position (Down).

2. Move the Ignition Switch to the OFF position.

Top Male Quick Disconnect

Couplers (Pressure Fluid Out)

Bottom Female Quick Disconnect

Couplers (Return Fluid In)

Flow Control Lever(s) In Off Position

Throttle Control Lever

COLD WEATHER STARTUP

1. Use the procedures described under “STARTUP”

and then follow the procedure below.

2. Hydraulic uids are thicker in cold weather.

Therefore, it is recommended that the engine

be run at low idle long enough to bring the uid

temperature up to a minimum of 50 °F/10 °C.

3. If the tools and tool hoses are cold, it is

recommended to allow hydraulic uid to circulate

through the tool hoses until warm before using the

tool.

NOTICE

If the engine runs out of gas or dies during operation

and the ignition switch is left in the ON or RUN

position, this could drain the battery. Make sure the

ignition switch is returned to the OFF position.

Starter Switch

OPERATION