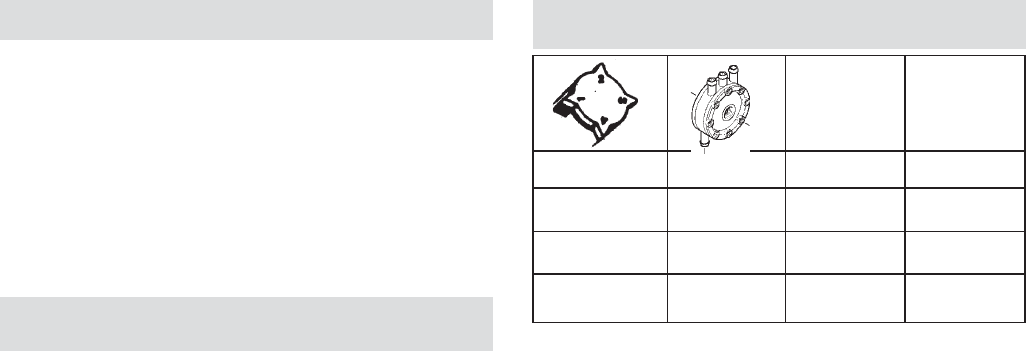

16

Position 1

Position 2

Position 3

Position 4

B

A*

C

Misting Output Guide (Fig.7)

Adjustment of carrying strap

Place the machine on the operators back and

click both strap connectors to the frame.

The straps can be adjusted to the required

length with friction slides.

Note: The shoulder straps are correctly adjus-

ted when the back plate of the mistblower

rests firmly against the back of the operator.

Operating Hints

• Before every use and before every start of

the mistblower check and ensure the machi-

ne is in good and safe condition. (throttle

operation, ignition switch, safety devices,

shoulder strap and check for fuel leaks)

• During the starting procedure and while

operating the mistblower, the operator

must have secure footing and have a safe

body position.

• The engine starting site should be at least

3 meters away from the refueling site.

Spraying (Fig. 6)

To open on tap: Move lever upwards into

position "I".

To shut off tap: Move lever into horizontal

position "O". When shutting tap, move lever

slowly against spring tension to position "0".

Do not let the lever flick back.

Note: For spot spraying (treatment of single

plants or smaller area), push the lever momen-

tarily into position "2" (spotspraying). The

correct output is obtained according to dosa

-

ge-sleeve setting

For area treatment or misting trees we re

-

commend the use of the wide angle nozzle

(fig.8a) on top of the standard nozzle (fig.8b).

This will increase the spray distance with

more even droplet size. The wide angle nozzle

is pushed over the standard nozzle until it

clicks over the retaining lip on the standard

nozzle.

For the treatment of row crops (vines, to-

matoes, tree nurseries), the deflector screen

(Fig.8d) should be used. This will ensure good

coverage on the underside of leaves.

The deflector screen can be replaced with

the double screen (Fig.8e). This screen pro-

duces a divided spray stream at an angle of

approx. 90deg.-110deg. and is mainly used for

spraying both sides of a row. Both deflector

screen as well as double screen are pushed

over the end of the cap nozzle (Fig. 8c).

The cap nozzle (Fig.8c), complete with the

required screen is fitted to the end of the

standard nozzle.

For narrow crops and for repeat applications,

the use of the diffuser screen (Fig.8f) toge-

ther with the wide angle nozzle (Fig.8a) is

recommended. The diffuser screen softens the

impact of air blast and reduces the damage to

leaves and tender shoots.

*) =The output values with use of liquid boos

-

ter pump are valid for all spray

tube positions

0,32 L/min

0,63 L/min

1,03 L/min

1,46 L/min

0,17 L/min

0,31 L/min

0,54 L/min

0,65 L/min

0,33 L/min

0,54 L/min

1,04 L/min

1,42 L/min