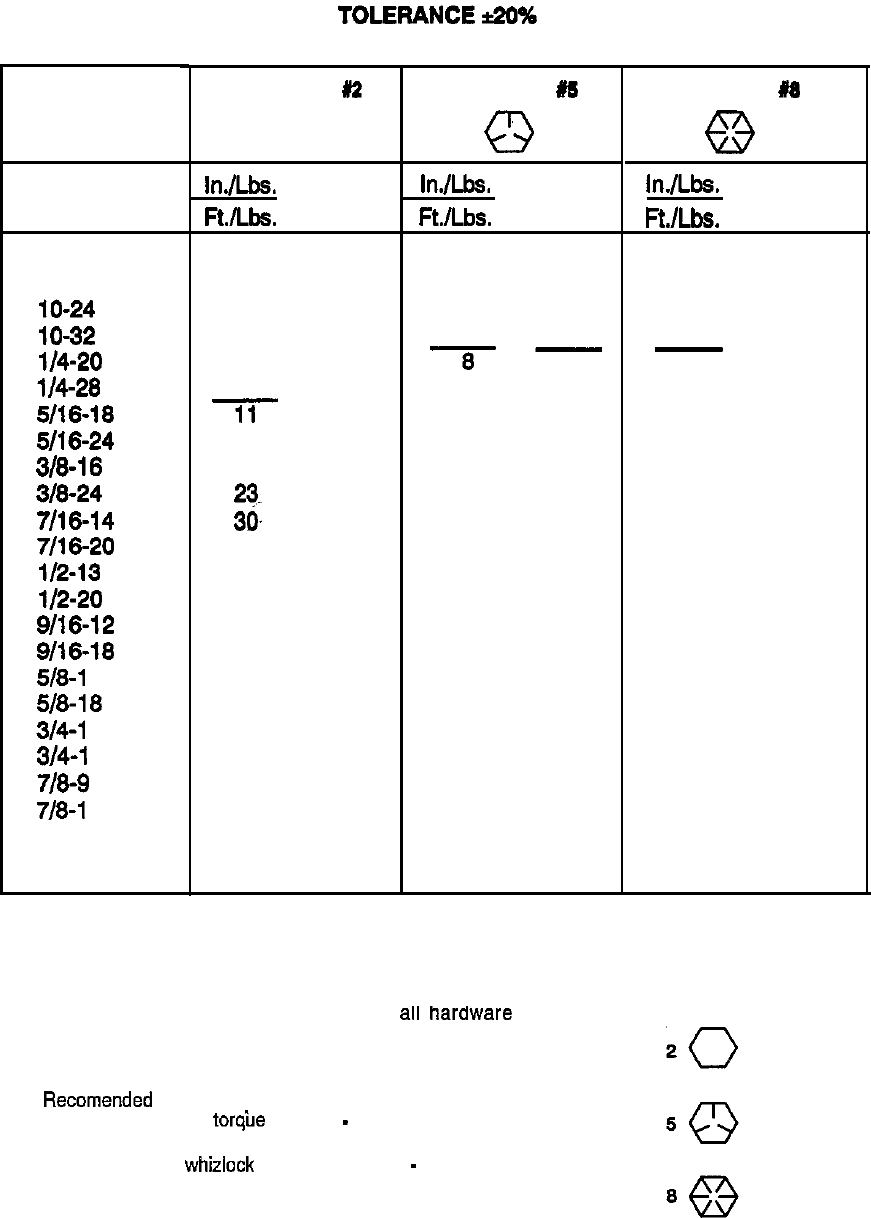

TORQUE SPECIFICATIONS FOR

STANDARD MACHINE HARDWARE

SEE

SAE GRADE #2

0

InJLbs.

In./Lbs.

In.1Lb.s.

FtJLbs.

Nm.

FtAbs.

Nm.

FtJLbs.

Nm.

8-32 19

2.1

8-38 20

2.3

lo-24 27

3.1

lo-32

31 3.5

114-20

66

7.8

114-28

78

8.8

5118-18

11

15.

5118-24

12

18.3

318-18

20

27.2

318-24

23.

31.3

7/18-14

30.

40.8

7/16-20

35

47.8

l/2-13

50

88.

l/2-20

55

74.8

9118-12

85

88.4

9118-18

75

102.

518-I

1 90

122.4

518-18

100

138.

314-I 0

180

217.8

314-I 8

180

244.8

718-9

140

190.4

718-I 4

155

210.8

l-8

220

299.2

l-12

240

328.4

SAE GRADE

#S

Q

30

3.4

31 3.5

43

4.9

49

5.5

8

10.9

10

13.8

17

23.1

19

25.8

30

40.8

35

47.8

50

88.

55

74.8

75

102.

90

122.4

110

149.8

120

183.2

150

204.

180

244.8

280

353.8

300 408.

400 544.

440

598.4

580

788.8

840

870.4

SAE GRADE 88

Q

41

43

80

68

12

14

25

25

45

50

70

80

110

120

150

170

220

240

388

420

800

880

900

1,000

4.8

4.9

8.8

7.7

18.3

19.

34.

34.

81.2

68.

95.2

108.8

149.8

183.2

204.

231.2

299.2

328.4

525.

571.2

818.

897.6

1,224.

1.360.

NOTE:

BOLT HEAD MARKING

S.A.E. GRADE:

1. These torque values are to be used for

all “araware

excluding: locknuts, self-tapping screws, thread forming

screws, sheet metal screws and socket head setscrews.

2.

Recomended seating torque values for locknuts:

a. For prevailing torqix locknuts

-

use 65% of grade 5

torques.

b. For flange

whizlock

nuts (and screws)

-

use 135%

of grade 5 torques.

3.

Unless otherwise noted on assembly drawings all torque

values must meet this specification.