6

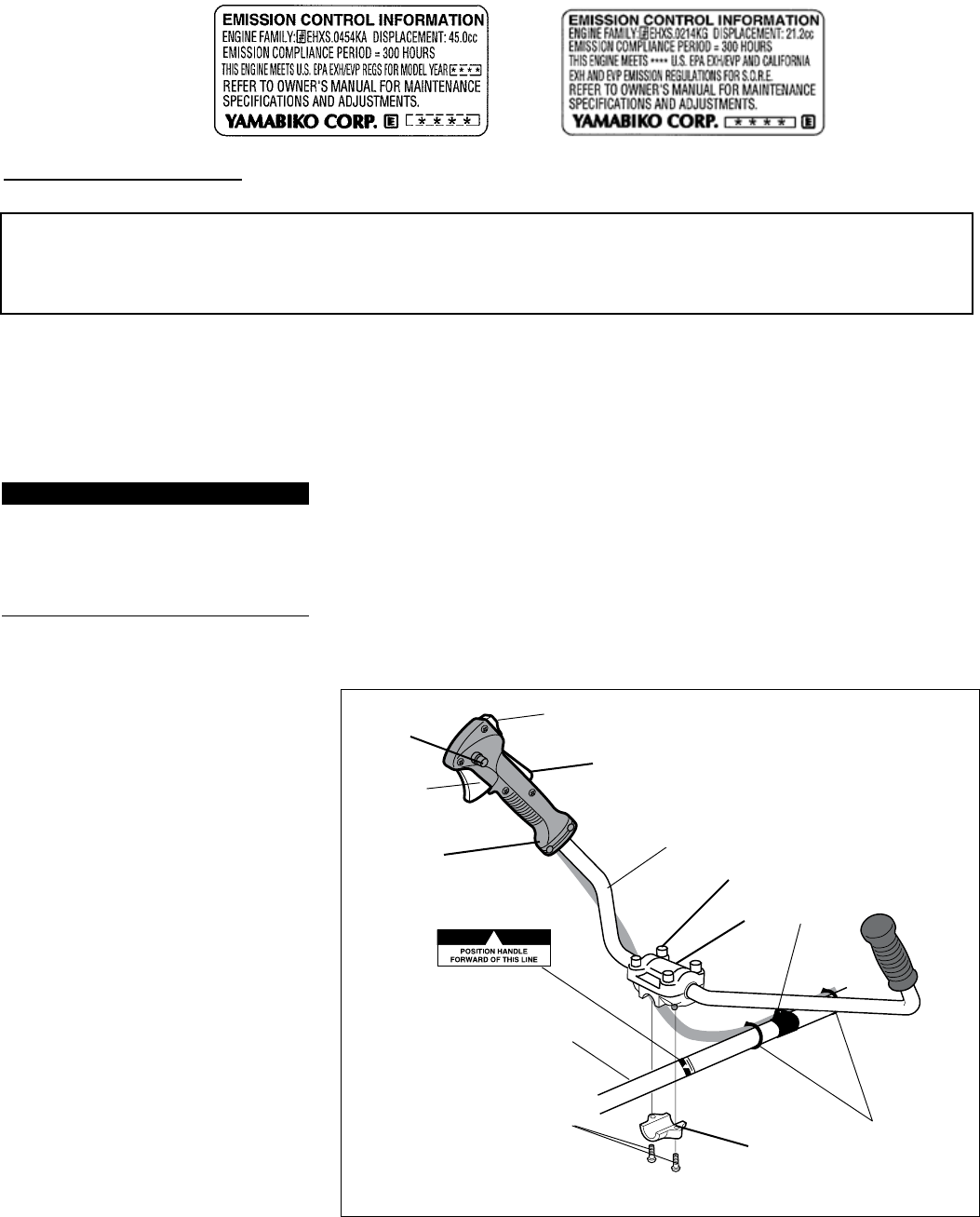

Handlebar and Throttle assemblyŶ

Handlebar C unit

Install the handlebar:

Use the 4 mm hex wrench to remove the 1.

lower cap retaining screws from the

handlebar bracket. Remove the cap

from the bracket.

Position the handle on the outer tube for-2.

ward of Handle Positioning Label as

shown. Reassemble the lower cap to the

handlebar bracket in the reverse order

of disassembly.

Locate the handle in the best position for 3.

operator comfort.

Firmly tighten both lower cap retaining 4.

screws.

Secure the cable to the outer pipe with the 5.

2 bands as the illustration shows. The 2

bands are in the tool bag.

Outer tube

Lower cap

retaining

screws

Handlebar

Ignition switch

Throttle

trigger

Hanger

Mounting the brushcutter handlebar

Handle positioning

label

Bands

6

Assembly

This unit comes fully assembled with the

exception of the cutting attachment shield

and cutting attachment.

Prior to Assembly

Before assembling, make sure you have all

the components required for a complete

unit and inspect unit and components for

any damage.

Engine and shaft assembly

Ŷ

Cutting attachment shieldŶ

Cutting attachmentŶ

Kit containing cutting attachment Ŷ

shield, mounting bracket and hardware,

this owner’s/operator’s manual and tool

kit for routine maintenance. Tool kits

vary by model and may include a spark

plug/screwdriver combination wrench,

and a scraper.

IMPORTANT!

The terms “left”, “left-hand”, and “LH”;

“right”, “right-hand”, and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation.

This unit comes fully assembled with the

exception of the cutting attachment shield

and cutting attachment.

Assembly

Prior to Assembly

Before assembling, make sure you

have all the components required for

a complete unit and inspect unit and

components for any damage.

Engine/Outer tube assembly

■

Handlebar and Throttle assembly ■

Cutting attachment shields ■

This unit comes fully assembled with

the exception of the handlebar, cut-

ting attachment shield and cutting

attachment.

Cutting Attachment

■

Shoulder Strap w/Hip Pad ■

Cutting attachment shield mounting ■

brackets and assembly hardware

Cutting attachment adapter plates

■

4 mm hex key wrench (Also use as ■

a locking tool)

T-wrench

■

IMPORTANT!

The terms “left”, “left-hand”, and

“LH”; “right”, “right-hand”, and “RH”;

“front” and “rear” refer to directions as

viewed by the operator during normal

operation.

An Emission Control Label is located on the unit. (This is an EXAMPLE ONLY; information on label varies by en-

gine FAMILY).

PRODUCT EMISSION DURABILITY (EMISSION COMPLIANCE PERIOD)

The 300 hour emission compliance period is the time span selected by the manufacturer certifying the engine

emissions output meets applicable emissions regulations, provided that approved maintenance procedures are

followed as listed in the Maintenance Section of this manual.

Emission Control (Exhaust & Evaporative)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM/TWC (Engine Modication and 3-way Catalyst) and for the fuel tank

the Control System is EVAP (Evaporative Emissions) or N (for nylon tank). Evaporative emission may be applicable to

California models only.

Install the handlebar:

Remove four (4) upper cap retaining 1.

screws, and remove upper cap from

handlebar mounting bracket.

Place handlebar on mounting 2.

bracket, and secure with upper cap

and four (4) screws.

Adjust handlebar position for best 3.

operator comfort and control, then

tighten upper and lower cap retain-

ing screws securely.

Secure cable to outer tube with two 4.

(2) bands provided.

Throttle lock

button

Throttle interlock

Throttle

Assembly

Upper cap

retaining screws

Upper

cap

Lower cap

Handle bar

Handlebar Assembly