MAINTENANCE

2160 06/11 Maintenance Section 5-6

©2011 Alamo Group Inc.

MAINTENANCE

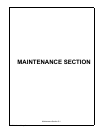

Proper Oil Level

Maintain the oil level within the sight gauge located

on the reservoir. When oil is cold, the level should

be three-quarters up the sight gauge. Never fill the

tank above that sight gauge level. A space is

maintained above the sight gauge to allow for the

expansion of the oil. Oil is added through the filler

tube, if your tank does not have a filler tube then fill

through the return filter located on the tank.

Thoroughly clean the cap area around the filter to

prevent oil from contamination. Remove the cap

and add the proper viscosity grade of FILTERED oil

to achieve the proper level. Never assume any oil is

clean, including new.

Oil Level Low

Low oil level in the reservoir is caused by leakage or improper filling. If leaking, locate the area of the leak and

repair the leak at once. Loss of fluid can cause severe & catastrophic damage to the hydraulic components.

NOTE: After initial start up, the mower may require more oil to bring the oil level back to the proper level. This

is normal. Air trapped in the hydraulic components was displaced by the oil, causing the oil level to go down in

the tank. Oil must be added to reach the proper level or cavitation could result.

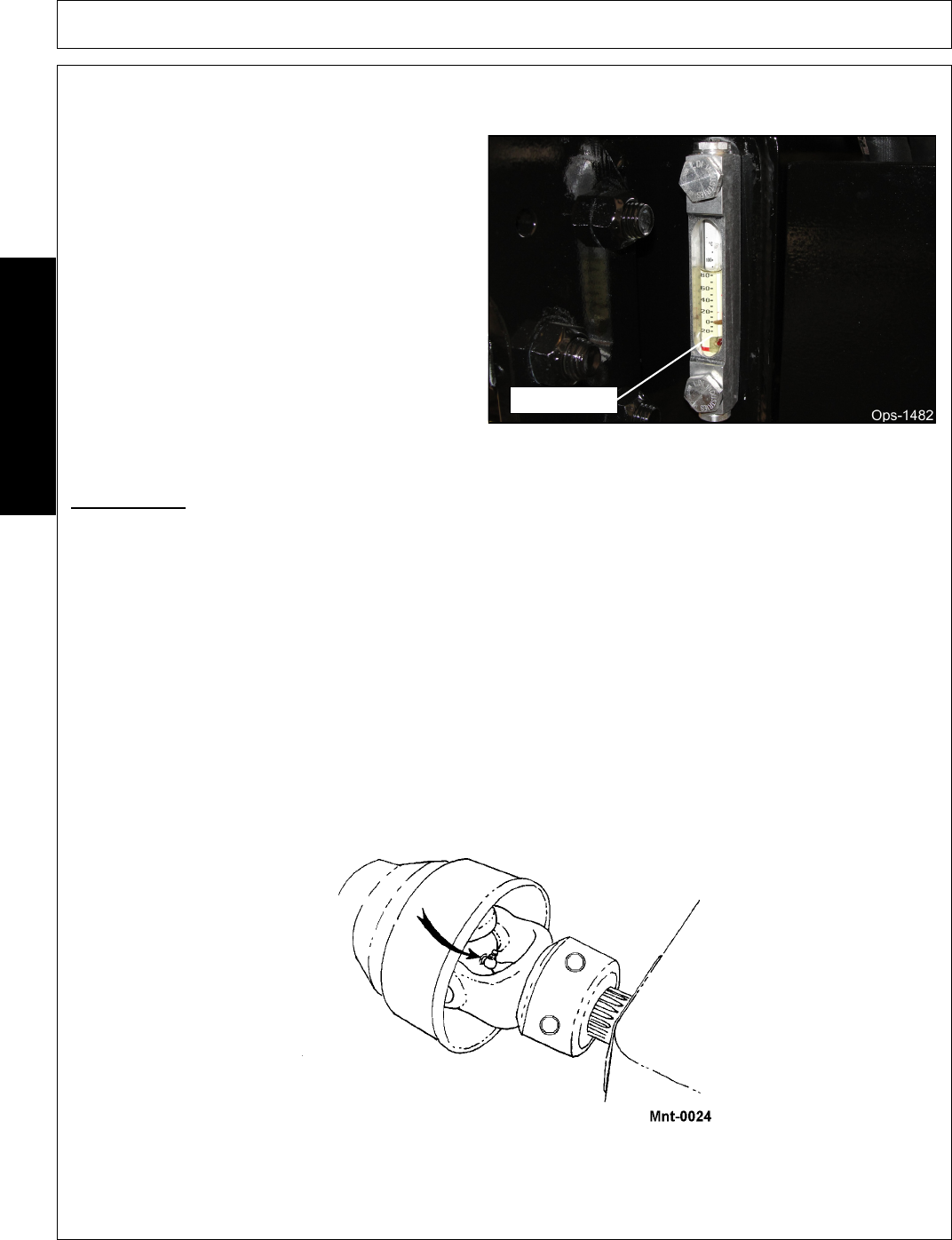

DRIVELINE LUBRICATION

Grease Fittings are located on the Cross Assembly of each U-Joint and on the telescoping tubes. Grease the

U-Joint after each 8 hours of use. Mnt-0024. Do not force grease through the Needle Cup Assemblies. Grease

the telescoping tubes after every 8 hours use. Some PTO-to-Hitch connections may necessitate cutting a hole

in the shields to be able to align the Grease Fitting holes for lubrication. Lubricate the shield bearings every 16

hours.

Sight Gauge

U-JOINT LUBRICATION