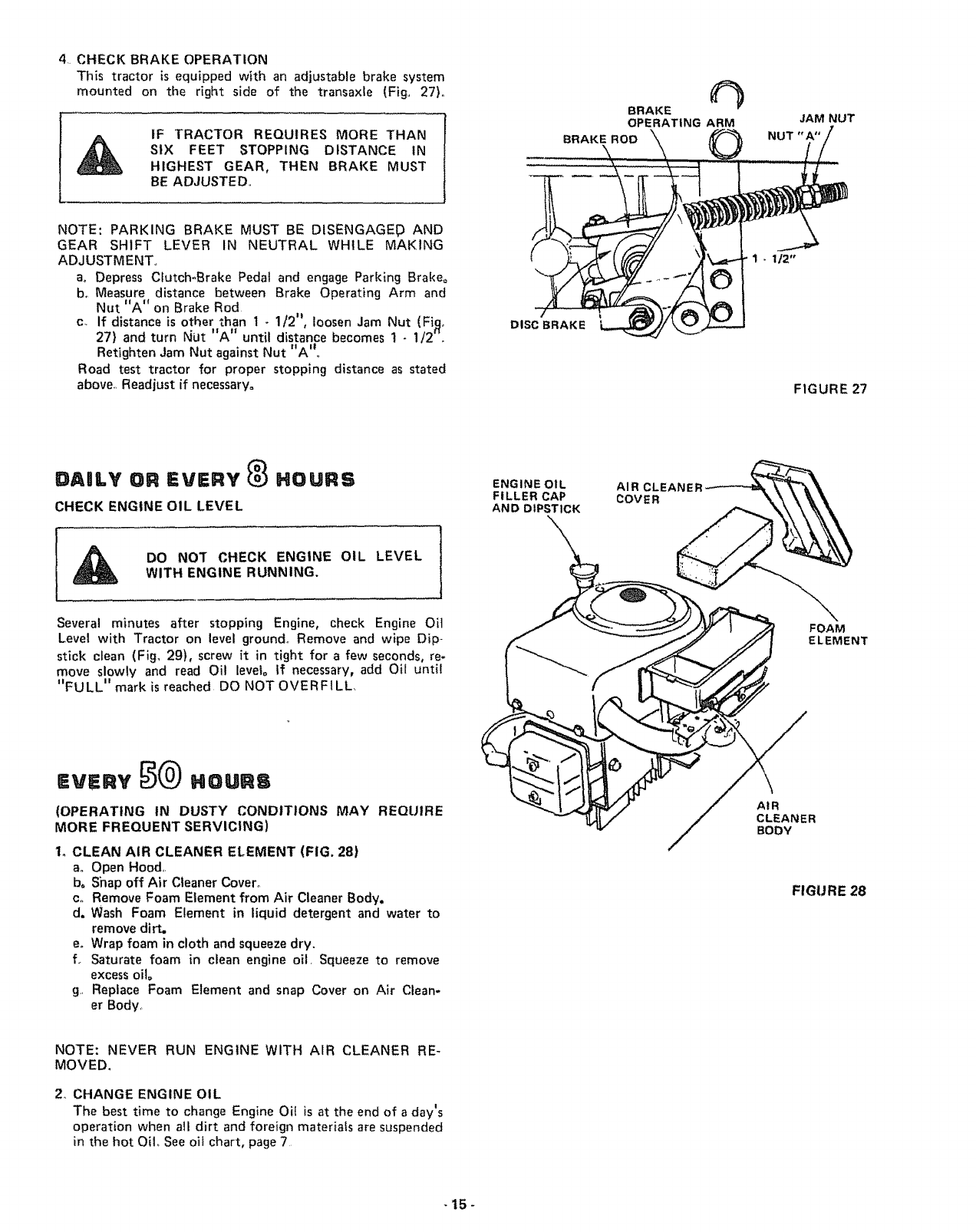

4, CHECK BRAKE OPERATION

This tractor is equipped with an adjustable brake system

mounted on the right side of the transaxle (Fig., 27).

tF TRACTOR REQUIRES MORE THAN

SIX FEET STOPPING DISTANCE tN

HIGHEST GEAR, THEN BRAKE MUST

BE ADJUSTED,,

NOTE: PARKING BRAKE MUST BE DISENGAGE D AND

GEAR SHIFT LEVER IN NEUTRAL WHILE MAKING

ADJ USTM ENT.,

ao Depress Clutch-Brake Pedal and engage Parking Brake°

bo Measure distance between Brake Operating Arm and

Nut "A" on Brake Rod

. . I)

c. if distance ts other than 1 - 1/2 , loosen Jam Nut (Fiq.

• is t_ . , /3

27) and turn NUt A untd d_stance becomes t - 1/2 .

* irl j

Retighten Jam Nut aga nst Nut A ,,

Road test tractor for proper stopping distance as stated

above.. Readjust if necessary=

BRAKE

OPERATING ARM

BRAKE ROD \

O, CBBAK

JAM NUT

0 ........

1.1/2-

0

F1GURE 27

G3

DAILY OR EVERY HOURS

CHECK ENGINE OIL LEVEL

DO NOT CHECK ENGINE OIL LEVEL

WITH ENGINE RUNNING.

ENGINE OIL

FILLER CAP

AND DIPSTICK

\

AIR

COVER

Several minutes after stopping Engine, check Engine Oil

Level with Tractor on level ground,, Remove and wipe Dip-

stick clean (Fig, 29), screw it in tight for a few seconds, re-

move slowly and read Oil level. If necessary, add Oil until

"FULL" mark is reached DO NOT OVERFILL

FOAM

ELEMENT

6vs.v .=..s

(OPERATING IN DUSTY CONDITIONS MAY REQUIRE

MORE FREQUENT SERVICING)

1. CLEAN AIR CLEANER ELEMENT (FIG. 28)

ao Open Hood,

b. Snap off Air Cleaner Cover°

c,. Remove Foam Element from Air Cleaner Body.

d. Wash Foam Element in liquid detergent and water to

remove dirt..

eo Wrap foam in cloth and squeeze dry.

f_ Saturate foam in clean engine oil Squeeze to remove

excessoil=

g,, Replace Foam Element and snap Cover on Air Clean-

er Body,

AIR

CLEANER

BODY

FIGURE 28

NOTE: NEVER RUN ENGINE WITH AIR CLEANER RE-

MOVED.

2. CHANGE ENGINE OIL

The best time to change Engine Oi{ is at the end of a day's

operation when all dirt and foreign materiafs are suspended

in the hot Oii_ See oil chart, page 7

-15-