..... i

z

' _r

CUSTO E RESPONSI LtTtES

ABR FILTER FOAM PRE-OLEANER (See Fig.

t6)

Your engine will not run properly and may be damaged by

using a dirty air filter, Cfean the foam pre-cleaner element

after every 25 hou rs of operation, more often if used in very

dusty, dirty conditions.

o Remove knob and cover.

o Remove cartridge nut and replace cartridge.

o Reassemble and tighten securely.

NOTE.: Do not attempt to clean or oii the paper cartridge.

Replace paper cartridge once a year or after every I00

hours of operation, more often if used in very dusty, dirty

conditions.

, Wash foam pre-cteaner in liquid detergent and water.

, Wrap foam pre°cleaner in cloth and squeeze dry.

o Lightly coat foam preocleaner with clean engine oil.

Squeeze in towel to remove excess oit. Do not satu-

rate.

, InstaII foam pre-cleaner over paper cartridge.

- Reassemble cover and secure with knobs.

COVER __.....,._z_

KNOB _-- T

COVER

_L.S PAPER

FOAM / i CARTRIDGE

PREoCLEANER

JL .

_'i'-,..__AgR CLEANER BASE

FiG, 16

AIR SCREEN (See Fig. I5)

The engine air screen must be kept free of dirt and chaff to

prevent engine damage from overheating. Clean with a

wire brush or compressed air to remove dirt and stubborn

dried gum fibers.

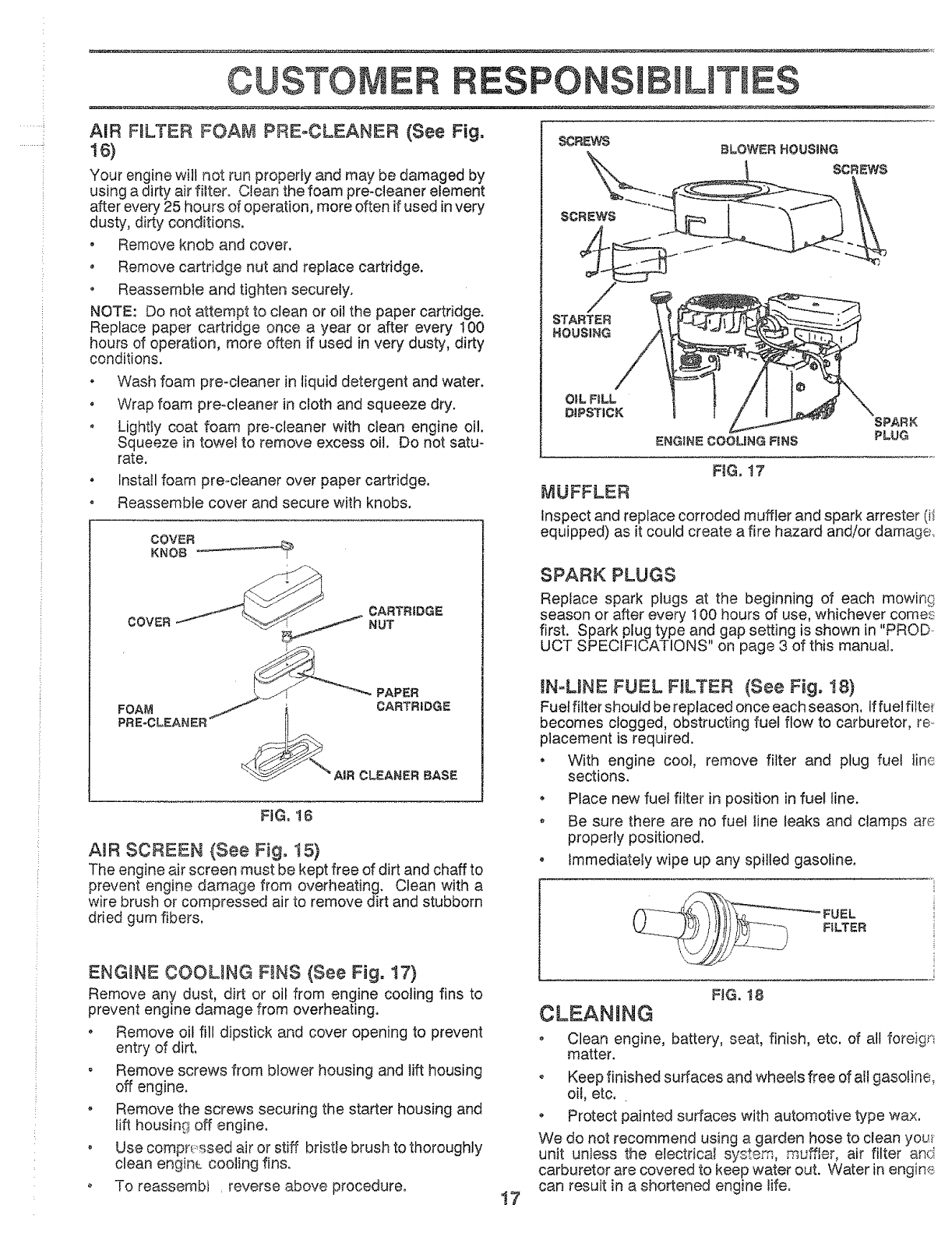

ENGINE COOUNG FINS (See Fig. t7)

Remove any dust, dirt or oil from engine cooling fins to

prevent engine damage from overheating,

, Remove oil fill dipstick and cover opening to prevent

entry of dirt,

• Remove screws from blower housing and lift housing

off engine.

• Remove the screws securing the starter housing and

lift housing off engine,

o Use compr_ssed air or stiff bristle brush to thoroughly

clean engin_ cooling fins.

o To reassembi _reverse above procedure.

SCREWS

BLOWER HOUSING

SCREWS

ENGINE COOMNG FIiNS

FiG. t7

MUFFLER

Inspect and replace corroded muffler and spark arrester (il

equipped) as it could create a fire hazard and/or damage.,

t7

SPARK PLUGS

Replace spark plugs at the beginning of each mowin!;

season or after every 100 hours of use, whichever come_

first. Spark plug type and gap setting is shown in "PROD ._

UCT SPECIFICATIONS" on page 3 of this manual.

IN-LINE FUEL FBLTER (See Fig. 18)

Fuel filter should be replaced once each season, iffue_filte_

becomes clogged, obstructing fuel flow to carburetor, re,,

placement is required,

= With engine coot, remove filter and plug fuel ]in<;

sections,

, Place new fuel filter in position in fuel line.

o Be sure there are no fuel line leaks and clamps arc

properly positioned,

o Immediately wipe up any spilled gasoline,

FILTER

F_G. 18

CLSANING

o Clean engine, battery, seat, finish, etc. of all foreign

matter.

, Keep finished surfaces and wheels free of al! gasoline,

oil, etc,

• Protect painted surfaces with automotive type wax.

We do not recommend using a garden hose to clean you_I

unit unless the electdcaf system, muffle_, air filter and

carburetor are covered to keep water out. Water in engin_

can result in a shortened engine lifeo