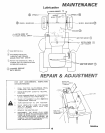

REPAIR

IDLER

TRANSAXLE

PULLEY

FIGURE 43

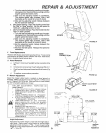

FIGURE 44

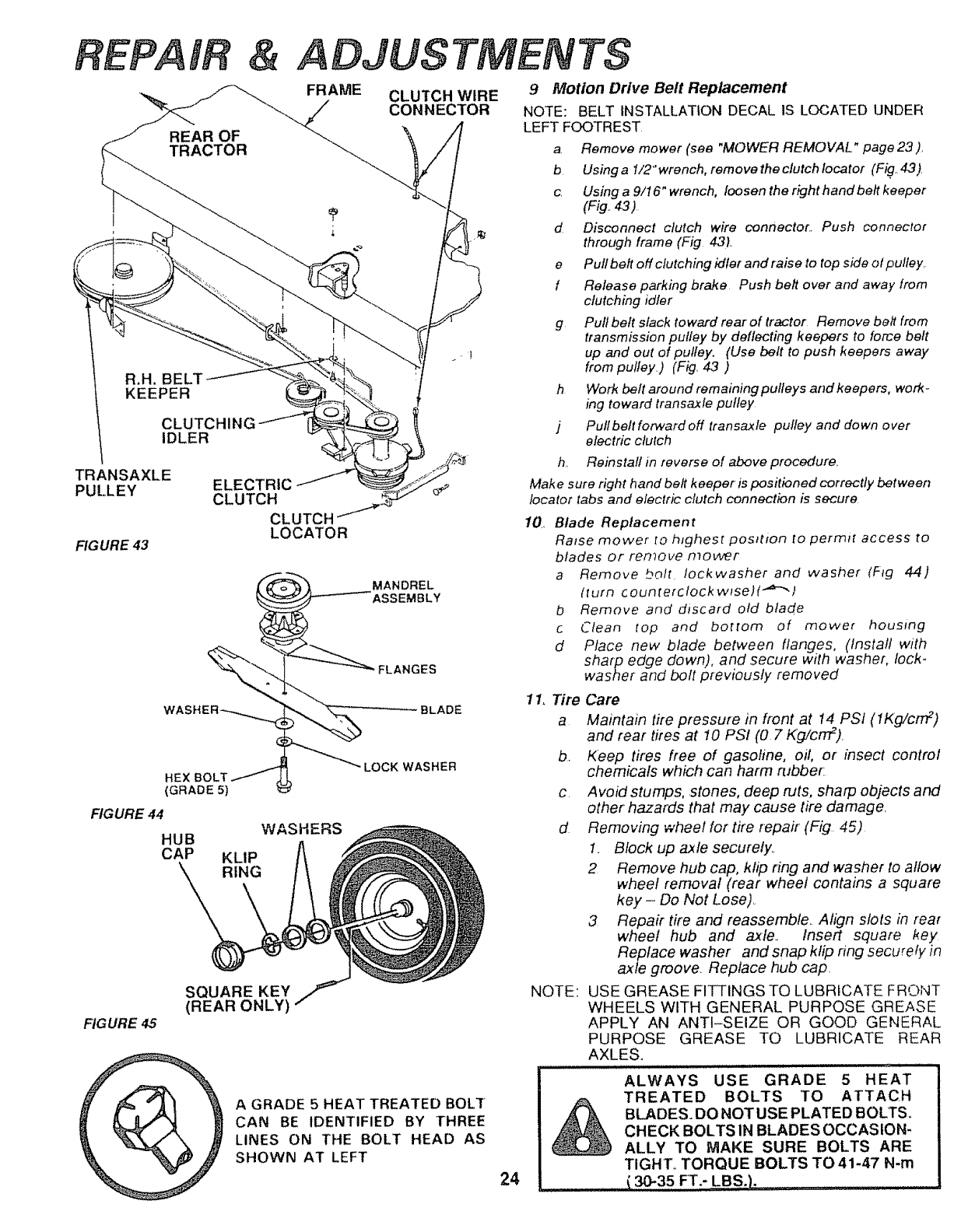

FIG URE 45

ELECTRIC

CLUTCH

& ADJUSTMENTS

FRAME

CLUTCH WIRE

CONNECTOR

9 Motion Drive Belt Replacement

NOTE: BELT INSTALLATION DECAL IS LOCATED UNDER

LEFT FOOTREST

a Remove mower (see "MOWER REMOVAL" page23).

b Using a 1/2" wrench, remove the clutch Iocator (Fig...43)

c Usingag/16"wrench, Ioosentherighthandbeltkeeper

(Fig. 4,3)

d Disconnect clutch wire connector. Push connector

through frame (Fig. 431,.

e Pull belt off clutching idler' and raise to top side otpultey,

f Release parking brake Push belt over and away from

clutching idler

g Pull belt slack toward rear of tractor Remove belt from

transmission pulley by deflecting keepers to force belt

up and out of pulley. (Use belt to push keepers away

from pulley.) (Fig, 43 )

h Work belt around remainingpulleys and keepers, work-

ing toward transaxle pulley

j Pullbeltforwardoff transaxle pulley and down over

electric clutch

h, Reinstall in reverse of above procedure,

Make sure right hand belt keeper' is positioned correctly between

locator tabs and electric clutch connection is secure

LOCATOR

HEX BOLT _ """ LOCK WASHER

(GRADE 5)

WASHERS

HUB

CAP KLIP

_ RING

SQUARE KEY

(REAR ONLY)

10 Blade Replacement

Rinse mower _ohighest positron fo permi_ access to

blades or remove mower

a Remove bolt Iockwasher and washer (F_g 44)

(turn counterclockw_se)(''_)

b Remove and discard old blade

c Clean top and bo[rom of mower housing

d Place new blade between flanges, (Install with

sharp edge down), and secure with washer, lock-

washer and bolt previously removed

11, Tire Care

a Maintain tire pressure in front at 14 PSt (tKg/crrF)

and rear tires at 10 PSI (0 7 Kg/cn'F),

b. Keep tPes free of gasofine, oil, or insect control

chemicals which can harm rubber:

c Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage,

d Removing wheel for tire repair (Fig 45)

1. Block up axle securely_,

2 Remove hub cap, klip ring and washer to allow

wheel removal (rear wheel contains a square

key - Do Not Lose),.

3 Repair tire and reassemble.. Align slots in rear

wheel hub and ax/e. Insert square key

Replace washer and snap kfip ring securely in

axle groove. Replace hub cap.

NOTE: USE GREASE FtTI'INGS TO LUBRICATE FRONT

WHEELS WITH GENERAL PURPOSE GREASE

APPLY AN ANTI-SEIZE OR GOOD GENERAL

PURPOSE GREASE TO LUBRICATE REAR

AXLES,

A GRADE 5 HEAT TREATED BOLT

CAN BE IDENTIFIED BY THREE

LINES ON THE BOLT HEAD AS

SHOWN AT LEFT

24

ALWAYS USE GRADE 5 HEAT

TREATED BOLTS TO ATTACH

BLADES. DONOTUSE PLATED BOLTS°

CHECK BOLTS IN BLADES OCCASION-

ALLY TO MAKE SURE BOLTS ARE

TIGHT,, TORQUE BOLTS TO 41-47 N-m

( 30-35 FT.- LBS,),

it ,l_,l