OIL AND FUEL INFORMATION

ASSEMBLY INSTRUCTIONS

12

RECOMMENDED OIL TYPE

Using the proper type and weight of oil in the

crankcase is extremely important. Check the

oil before each use and change the oil

regularly. Failure to use the correct oil, or

using dirty oil, can cause premature engine wear and

failure.

Use a high-quality SAE 30 weight oil of API (American

Petroleum Institute) service class SF, SG, SH.

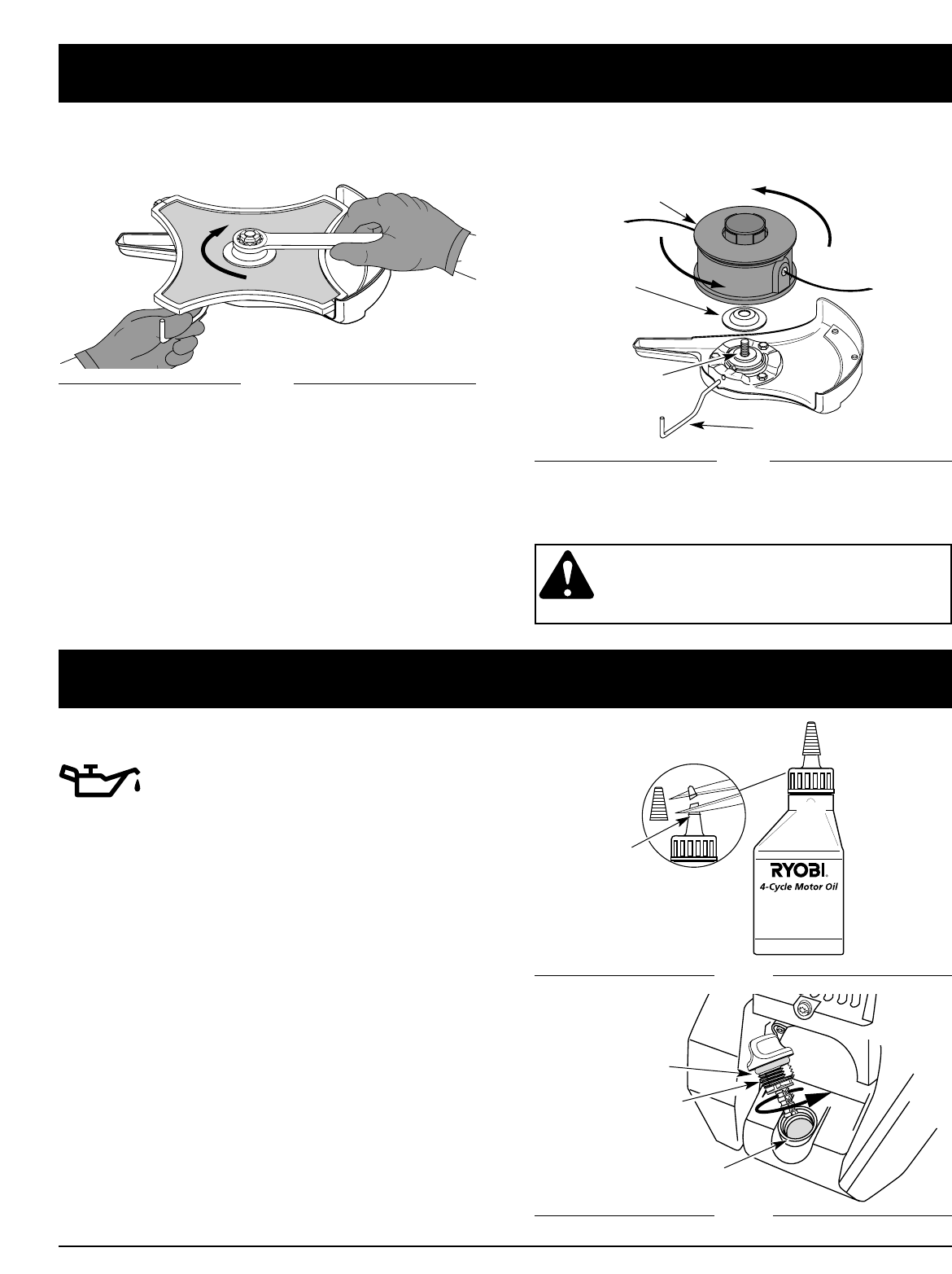

ADDING OIL TO CRANKCASE – INITIAL USE

NOTE: This unit is shipped without being filled with oil.

In order to avoid damage to the unit, put oil in

the crankcase before attempting to start unit.

Your unit is supplied with one 3.4 fluid oz. (100 ml.)

bottle of SAE 30 SF, SG, SH oil (Fig. 17).

NOTE: Save the bottle to measure the correct amount

for future oil changes. See Changing the Oil

Pg. 20.

1. Unscrew the top of the bottle of oil and remove the

paper seal covering the opening. Replace top. Cut

the tip off the funnel spout (Fig. 17).

2. Place the unit on a flat level surface.

3. Remove the oil plug / dipstick from the crankcase

(Fig. 18).

Fig. 17

Oil Fill Plug/Dipstick

Oil Fill Hole

Fig. 18

O-Ring

Funnel Spout

Cutting Attachment

Locking Rod

4. Remove the nut, blade retainer, and blade. Store the

nut and blade together for future use in a secure

place. Store out of reach of children.

Install the Cutting Attachment

5. Align the shaft bushing hole with the locking rod slot

and insert the locking rod into the shaft bushing hole.

(Fig. 8, Pg. 10). Place the blade retainer on the

output shaft with the flat surface against the output

shaft bushing as shown in Fig. 16. Screw the cutting

attachment counterclockwise onto the output shaft.

Tighten securely.

Clockwise

6. Remove the locking rod.

7. Install the cutting attachment shield. See Removing

and Installing Cutting Attachment Shield, Pg. 10.

WARNING: To avoid serious personal injury,

the cutting attachment shield SHALL be in

place at all times while operating the unit as

a grass trimmer.

3. While holding the locking rod, loosen the nut on

the blade by turning it clockwise with a 5/8 inch

closed-end or socket wrench (Fig. 15).

NOTE: The blade retainer must be installed on the

output shaft in the position shown for the cutting

attachment to work correctly.

Blade Retainer

Output Shaft

Bushing

Fig. 15

Fig. 16