ASSEMBLY INSTRUCTIONS

11

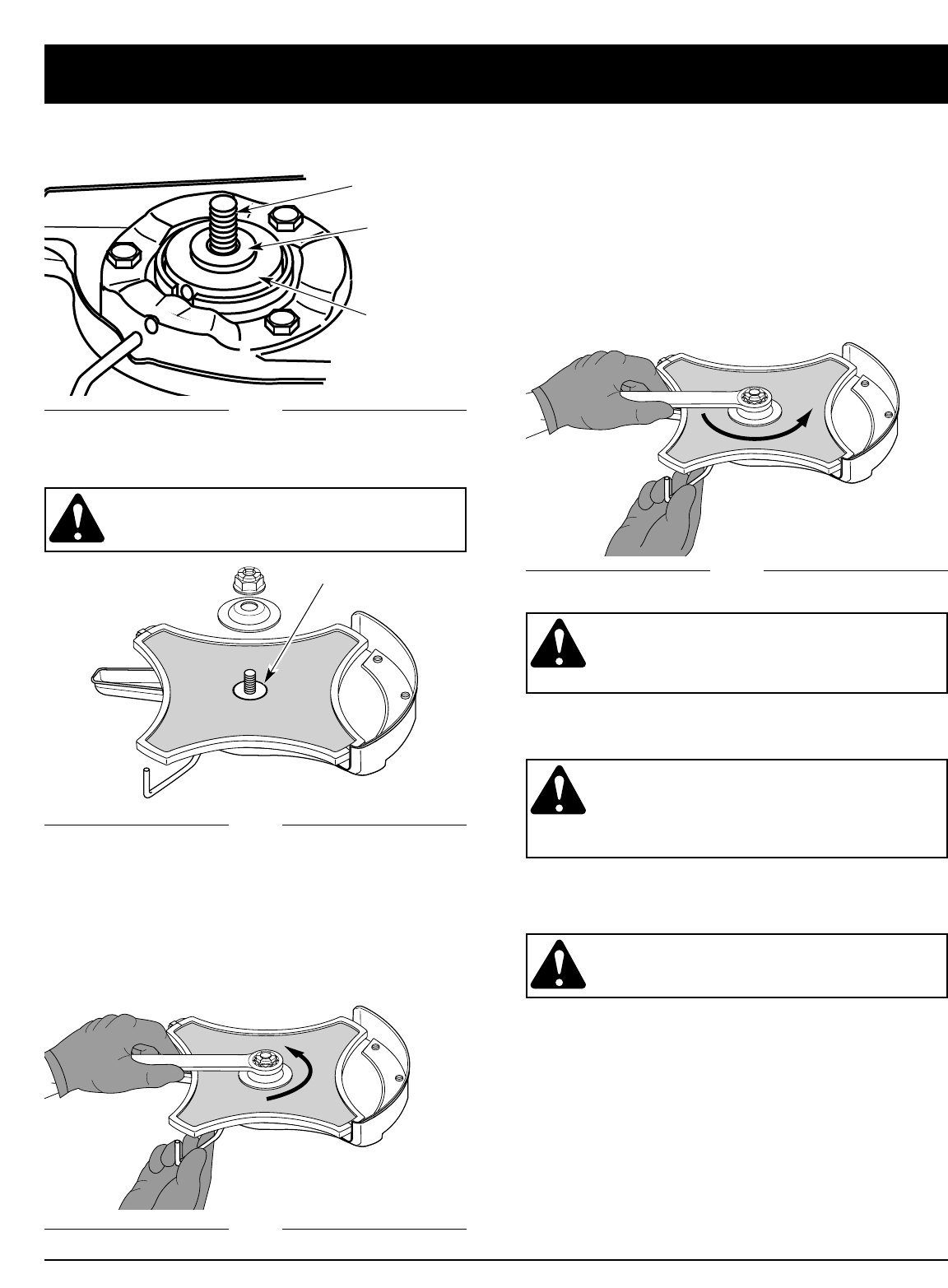

4. Center the cutting blade on the pilot step of the

output shaft bushing (Fig. 11).

Pilot Step

Output Shaft

Bushing

Output Shaft

Fig. 12

Fig. 13

Fig. 14

Fig. 11

5. Make sure that the cutting blade is centered on the

pilot step and sitting flat against the output shaft

bushing (Fig. 12).

WARNING: If the cutting blade is off-center,

the unit will vibrate, and the blade may fly off,

which can cause serious personal injury.

6. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the bushing hole

(Fig. 8).

7. Put the blade retainer and nut on the output shaft.

Make sure that the blade is installed correctly.

8. Tighten counterclockwise against the blade while

holding the locking rod (Fig. 13).

Counterclockwise

Pilot Step

9. Remove the locking rod from the locking rod slot.

WARNING: To avoid serious personal injury

or damage to the unit, do not start or operate

this unit with the locking rod in the locking

rod slot.

10. Remove the cutting blade cover by un-snapping the

plastic lock on the cover and pulling it from the

blade. Store the cover for future use.

WARNING: Do not sharpen the cutting

blade. Sharpening the blade can cause the

blade tip to break off while in use. This can

result in severe personal injury. Replace the

blade.

REMOVE THE CUTTING BLADE AND INSTALL

THE CUTTING ATTACHMENT

Remove the Cutting Blade

WARNING: To avoid serious personal injury,

always wear gloves while handling or

installing the blade.

1. Install the cutting blade cover. Pull the cover around

the blade and click the plastic lock.

2. Align the shaft bushing hole with the locking rod

slot and insert the locking rod into the bushing hole

(Fig. 8).

1/4-1/2 turn

Counterclockwise

• If using a torque wrench and an 5/8 inch socket

tighten to;

325 - 335 in•lb,

27 - 28 ft.•lb,

37 -38 N•m.

• Without a torque wrench, use a 5/8 inch closed-end or

socket wrench, turning the nut until the blade retainer

is snug against the shaft bushing. Make sure that the

blade is installed correctly, then rotate the nut an

additional 1/4 to 1/2 turn counterclockwise (Fig. 14).