10

101755

®

ELECTRIC CHAIN SAW

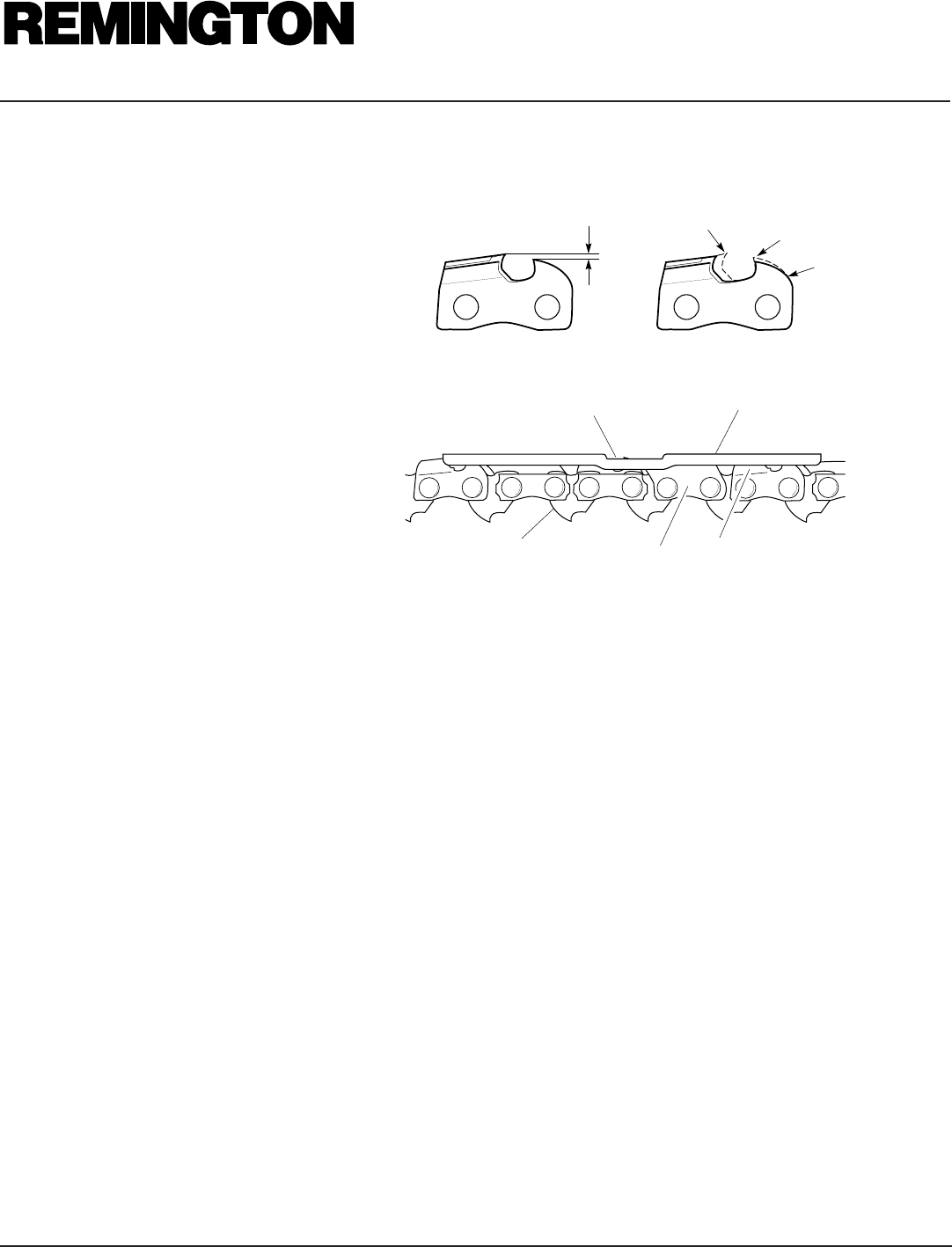

Correct Gauge

Clearance .025"

(0.64 mm)

Rounded

Off

As The Cutters

Are Filed Back

The Gauge

Must Be

Lowered

And

Figure 19 - Chain Depth And Clearances

Drive Link

Cutter

Side Link

Depth Gauge Set

Check Gauge

Clearance

FILING THE CUTTER DEPTH

GAUGES

The cutter depth gauge clearance is reduced

as the cutting edges are sharpened. The

cutter depth gauge clearance will need to be

set after every second or third sharpening.

1. Place the depth gauge set firmly across

the top of two cutters so the depth gauge

enters the slot in the gauge set.

2. With a flat file, use a firm forward

pressure to file gauge level with depth

gauge set.

3. Round off cutter gauge depth to

maintain original shape.

Note:

After several hand filings of the saw

chain it is a good practice to have your

authorized service center or sharpening ser-

vice shop precision sharpen the saw chain

on a sharpening machine to insure uniform

dimensions.

STORING YOUR CHAIN SAW

Follow these instructions when storing your

chain saw for more than 30 days.

1. Drain the oil reservoir.

2. Remove, clean and dry the guide bar

and chain.

3. Place the saw chain in a container filled

with oil to prevent rust.

4. Wipe on a coating of oil to the entire

surface of the guide bar and wrap in

heavy paper, cloth or plastic.

5. Wipe off the outside surfaces of the

saw.

6. Store the saw in a dry place out of the

reach of children.

Note:

It is normal for oil seepage to occur

when the saw is not in use. Empty the oiler

reservoir after each use to prevent lubricant

from seeping.

ACCESSORIES AVAILABLE

FOR YOUR CHAIN SAW

FROM YOUR DEALER

Part No. Description

097570-01S BAR, Guide 14" (350mm)

091374S CHAIN, Saw, 14" (350mm)

075752 SPROCKET, Drive

097572-03S BAR, Guide 16" (400mm)

091375S CHAIN, Saw, 16" (400mm)

MAINTENANCE

AND STORAGE

Continued