6

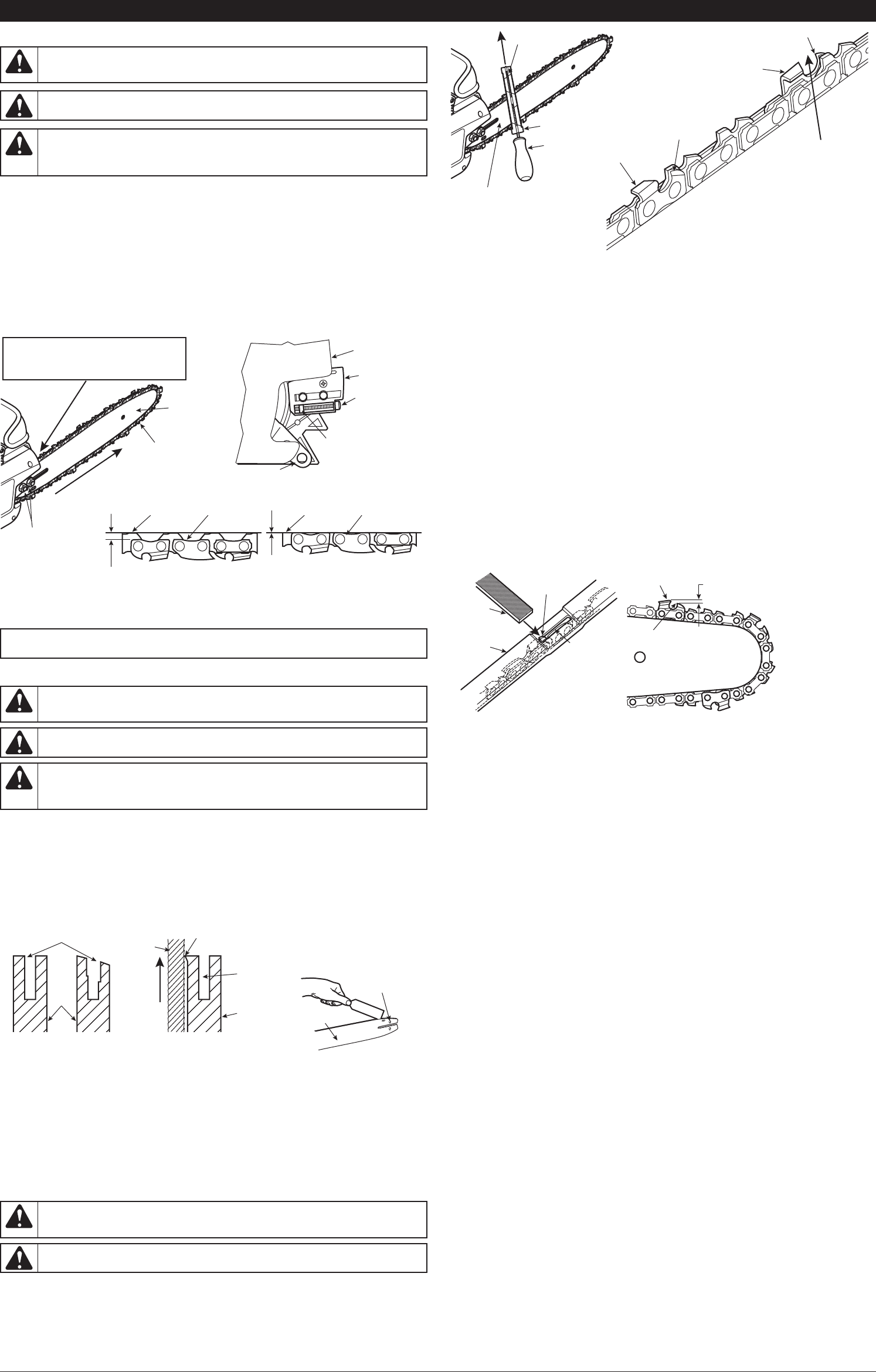

SAW CHAIN TENSION ADJUSTMENT

WARNING: Before you adjust the saw chain tension always unplug it from the main

power outlet. Otherwise severe injury or death may occur from electrical shock. Bodily injury

may also occur from accidental contact with the moving chain.

WARNING: The cutting edges on the chain saw are very sharp so always wear protective

gloves when handling the chain.

WARNING: Always maintain the correct chain saw tension because a loose chain will

increase the risk of dangerous kickback. A loose chain may also jump out of its guide bar

groove and may seriously injure you. This may also result in rapid wear and tear of the

chain, guide bar and sprocket.

NOTE: For pre-assembled chain saw models, the saw chain is correctly set at the factory. However, a

new chain will stretch after using it. It’s recommended that you check the new chain after the first few

minutes of operation. First of all, allow the chain to cool down and follow the steps below to correctly

readjust the saw chain tension:

1. Before adjusting the chain first make sure that the two guide bar nuts are only finger tight (Fig. 18).

Also make sure that the adjusting block is seated in the oval adjusting hole on the guide bar (Fig. 18).

2. Use a flat head screw driver and turn the adjusting screw clockwise (Fig. 18).

NOTE: There should be no gap between the links of the chain and the bottom of the guide bar. (See

Fig. 18)

3. Wearing protective gloves, move the chain around guide bar by hand. The chain should move

freely. If it doesn’t, loosen the chain by turning the adjusting screw counterclockwise.

4. After the chain tension is corrected, tighten the two guide bar nuts firmly. If this is not done the

guide bar will move and loosen the chain tension. This will increase the risk of kickback and may

also damage the saw.

Sprocket Support

Saw Chain

Close up view showing where the Adjusting Plate, Block and

Screw are located behind the Guide Bar (The Saw Chain,

Guide Bar, Saw Chain and Nuts removed for clarity)

The Adjusting Plate is located directly behind

the Guide Bar. Turn the Adjusting Screw to

move the Guide Bar along. This tightens or

loosens the tension of the Saw Chain.

Before adjusting Saw

Chain tension, make

sure that the Guide Bar

Nuts are only finger tight

to allow the Guide Bar

to move along.

Adjusting Plate

Adjusting Block (this

grips and moves the

Guide Bar along)

Sprocket Support

Adjusting Screw

(when turned,

moves the

Adjusting Block)

Motor Housing

Guide Bar

Incorrect Tension: Too much space

between underside of Guide Bar

and Saw Chain

Correct Tension: Saw Chain slides on

and along underside of Guide Bar

Guide BarSaw Chain Saw Chain

Guide Bar

Fig. 18 Use the Adjusting Screw to correct

CLEANING AND MAINTENANCE

NOTICE: These are instructions for servicing your chain saw. Any servicing that is not mentioned

here should be done by an authorized service center.

HOW TO KEEP YOUR CHAIN SAW CLEAN

WARNING: Before you service the chain saw always unplug it from the main power

outlet. Otherwise severe injury or death may occur from electrical shock. Bodily injury may

also occur from accidental contact with the moving chain.

WARNING: The cutting edges on the chain saw are very sharp so always wear protective

gloves when handling the chain.

WARNING: Whenever you clean the chain saw body make sure that:

DO NOT submerge the chain saw in any liquids.

DO NOT use products that contain ammonia, chlorine or abrasives.

DO NOT use chlorinated cleaning solvents, carbon tetrachloride, kerosene or gasoline.

Keep the chain saw body clean by wiping with a soft cloth dampened with a mild soap and water mixture.

HOW TO TAKE CARE OF THE GUIDE BAR

Uneven wear on the guide bar causes most chain saw cutting problems. Incorrect sharpening of the

chain cutter and incorrect depth gauge settings often cause this. When the guide bar wears unevenly

it widens the guide bar groove. This may then cause the chain to clatter and for rivets to pop out. As a

result the chain saw will not cut straight. If this happens, it is advisable to replace the guide bar.

Inspect the guide bar before sharpening the chain. A worn or damaged chain is unsafe.

Normal Guide Bar Maintenance

Guide Bar

with Burr

Flat

File

Remove any Burrs

with a Flat File

Guide Bar with

Uneven Wear

Guide

Bar

Guide Bar with

Normal Wear

Guide Bar Groove

Clean Oil Slots

after each day

of use

Remove any debris from

Guide Bar Groove with

a putty knife or wire

Guide

Bar

Guide

Bar

Guide Bar

Groove

Fig. 19 Cross Section View of Guide Bar Groove showing Normal and Uneven Wear

1. Remove the guide bar from the chain saw (Fig. 19).

2. Use a putty knife or wire to remove any sawdust from inside the guide bar groove (Fig. 19)

3. Clean oil slots after each day of use.

4. Use a flat file to remove any burrs from the sides of the guide bar and to make the edges square.

It is recommended that you replace the guide bar whenever the following happens:

• When the guide bar is bent or cracked.

• When the inside of the groove of the guide bar is badly worn.

NOTE: When replacing the guide bar, see the Safety Information section for the correct part numbers.

HOW TO KEEP YOUR CHAIN SAW SHARP

WARNING: Before you service the chain saw always unplug it from the main power

outlet. Otherwise severe injury or death may occur from electrical shock. Bodily injury may

also occur from accidental contact with the moving chain.

WARNING: The cutting edges on the chain saw are very sharp so always wear protective

gloves when handling the chain.

Keep the chain saw sharp as it will cut faster and more safely. A dull chain will cause undue wear and

tear on the sprocket, guide bar, chain and motor. You will know that the chain has become dull when

you experience the following:

• It takes more effort to cut and have to force the chain saw into the wood.

• Only saw dust is created with few large chips

Filing

Direction

30° Guide

Mark

Filing

Guide

5/32”

Round

File

Clamp the Guide Bar in a

vise to hold the chain saw

steady but do not clamp

the chain.

Top Plate of Cutter

(right side of chain)

Top Plate of Cutter

(left side of chain)

Depth Gauge

(right side

of chain)

Depth Gauge

(left side

of chain)

Filing

Direction

File from inside towards

the outside of the the Cutter

until it is sharp. Only file in

this one direction. Two or

three strokes with the file

should be enough to

sharpen each cutter.

Fig. 20 File and File Guide Placement on the Chain

Items Needed to Sharpen Chain Saw Cutter Teeth

These tools can be purchased from your local dealer, hardware store or chain saw supply outlet.

• 5/32” Round File

• Depth gauge tool

• File guide

• Vise

• Medium sized flat file

1. Adjust the chain to set the proper tension (see saw Chain Tension Adjustment section).

2. Clamp the guide bar in a vise to hold the chain saw steady.

NOTE: Do not clamp the chain.

3. Press the 5/32” round file, attached to file guide, into groove between the top plate and the depth

gauge on the chain. The file guide should rest on both the top plate and depth gauge (Fig. 20).

NOTE: File the midpoint of the guide bar.

4. Hold the file at guide level. Make sure that the 30° mark on the file guide is parallel to the center of

the guide bar (Fig. 20). This will ensure that you file the cutters at a 30° angle.

5. File from inside towards the outside of the cutter until it is sharp. Only file in this one direction

(Fig. 20).

NOTE: Two or three strokes with the file should be enough to sharpen each cutter.

6. After each cutter is sharpened, move the chain forward to sharpen the next cutter. File all the

cutters on one side of the chain.

7. Move to other side of chain and repeat the process of sharpening the remaining cutters.

How to Reset the Depth Gauge Clearance on the Chain Saw

Depth Gauge

Depth

Gauge

Tool

Flat File

Depth

Gauge

Slot

Top Plate

of Cutter

.025”

Front corner of

Depth Gauge

The cutter depth

gauge clearance is

reduced as cutters

are sharpened.

So after every second

or third sharpening it

is necessary to reset

the depth gauges.

Fig. 21 Use a Flat File to reset the Depth Gauge Clearance

The cutter depth gauge clearance is reduced as cutters are sharpened. So after every second or third

sharpening it is necessary to reset the depth gauges.

1. Place the depth gauge tool (.025”) firmly across the top of two cutters. Make sure that the depth

gauge enters the slot inside the depth gauge tool (Fig. 21).

2. Use the medium sized flat file and file depth gauge level with the depth gauge tool.

3. Remove the depth gauge tool. Use the flat file to round off the front corner of the cutter depth

gauge (Fig. 21).

After several hand filings, it is recommended that you take your chain saw to an authorized service

center or sharpening service. They will machine sharpen it to insure accurate and even filing.

MAINTENANCE AND REPAIR INSTRUCTIONS