5

104673

OWNER’S MANUAL

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping dam-

age. If you find any damage or if any

parts are missing, promptly inform

dealer where you bought the Pole Saw.

ASSEMBLY

The plastic hardware bag for the Pole Saw

should include the following:

CHAIN SAW HARDWARE

• (2) Guidebar bolts

• (2) Guidebar nuts

• (1) Phillips self tapping screw

• (1) Saw chain

• (1) Guide bar

• (1) Hand guard

• (1) Scabbard

POLE SAW HARDWARE

• (1) Handle bracket

• (4) #10 x 24 Phillips screws

• (4) #10 lockwashers

ASSEMBLY OF CHAIN SAW

Assemble the chain saw before assembling

the pole. Refer to chain saw manual for

assembly instructions.

®

®

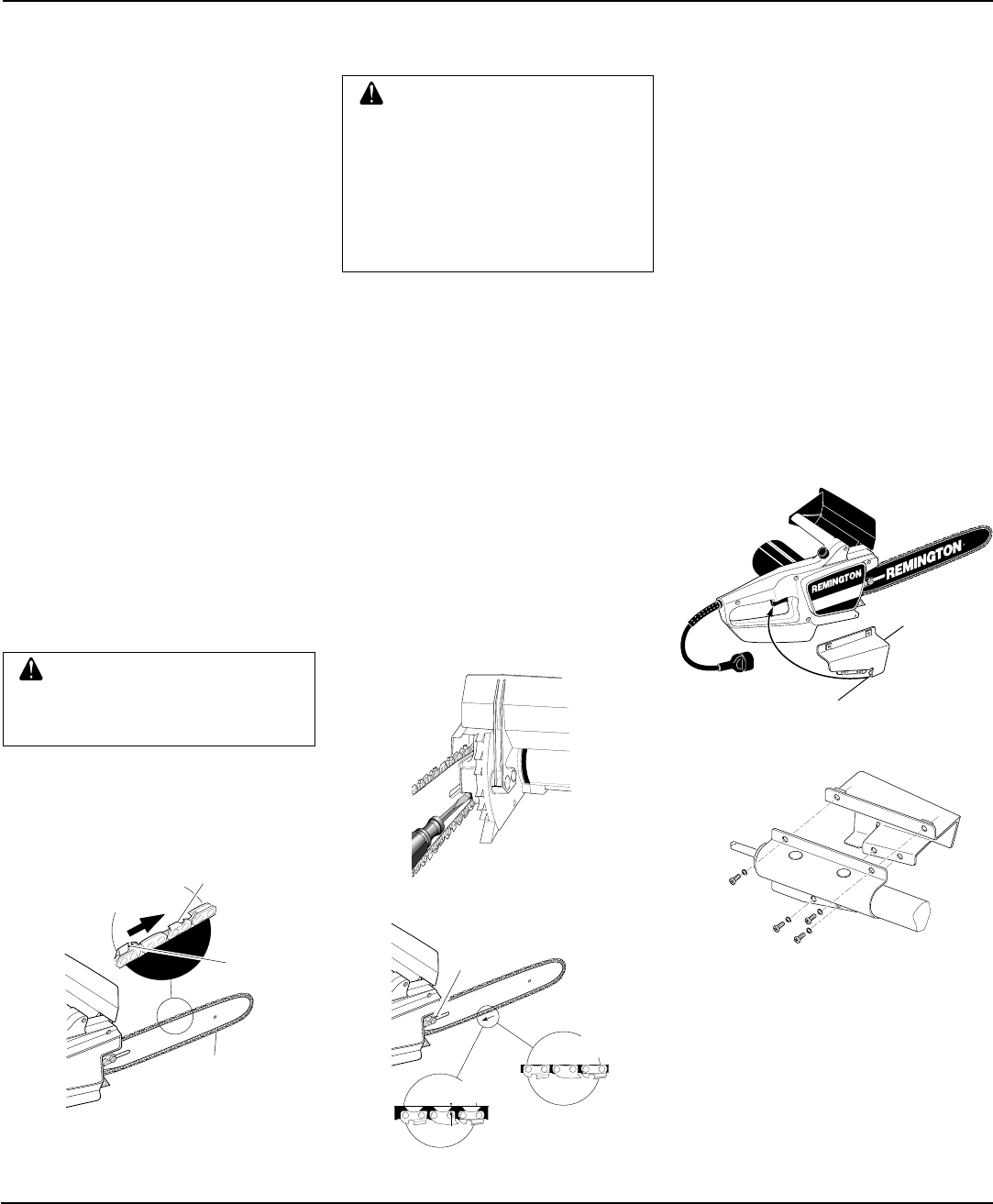

Figure 5 - Bracket with Trigger Support

Trigger

Support

Bracket

Figure 6 - Assembly of Pole Saw Brackets

ASSEMBLY OF POLE SAW

1. Slip handle bracket over chain saw

handle from the right side (see Figure 5).

Note:

The trigger must be depressed

before the bracket will go onto the

handle.

Push the lockout button and depress the

trigger. While holding the trigger in,

place the trigger support portion of the

bracket under the trigger and slide the

bracket onto the chain saw handle. The

bracket will keep the trigger in the “on”

position.

2. Align holes in pole bracket with holes

in handle bracket. Install Phillips head

screws with lockwashers through pole

bracket from left side and thread into

the weld nuts on the handle bracket.

Tighten screws securely by hand.

3. Plug the saw power cord into receptacle

cord at end of inner pole.

CAUTION: Do not place chain

on saw backwards. If chain is

backwards, saw will vibrate badly

and will not cut.

Make sure cutting edges of chain are facing

in the right direction. Position chain so cut-

ting edges on top of guide bar face guide bar

nose (see Figure 2).

Figure 2 - Chain Position

SAW CHAIN TENSION

ADJUSTMENT

WARNING: Maintain proper

chain tension. A loose chain will

increase the risk of kick back. A

loose chain may jump out of

guide bar groove. This may in-

jure operator and damage chain.

A loose chain will cause chain,

guide bar and sprocket to wear

rapidly.

1. To adjust chain tension, make sure

guide bar nuts are only finger tight.

Also make sure adjusting block is in

oval adjusting hole on guide bar.

2. Turn adjusting screw clockwise until

all slack is out of chain.

Note:

There

should be no gap between side links of

chain and bottom of guide bar.

3. Wearing protective gloves, move chain

around guide bar. Chain should move

freely. If chain does not move freely,

loosen chain by turning adjusting screw

counterclockwise.

4. After chain tension is correct, tighten

guide bar nuts firmly. If not, guide bar

will move and loosen chain tension.

This will increase the risk of kickback.

This can also damage saw.

Figure 4 - Saw Chain Adjustment

Towards

Guide Bar

Nose

Cutting

Edge

Cutting

Edge

Saw

Chain

Correct Tension

Gap

Incorrect Tension

Guide Bar

Nuts

Guide Bar

Guide Bar

Figure 3 - Turning Adjusting Screw