17

ENGLISH

www.remingtonpowertools.com

Figure 34 - Depth Gauge Tool On

Chain

Figure 35 - Round Off Front Corner Of

Depth Gauge

Front

Corner

.025"

Flat File

Depth Gauge

Tool

Depth Gauge

Continued

CLEANING AND MAINTENANCE

WARNING: Remove battery

from chain saw before adjusting

saw chain tension.

Severe injury

or death could occur from body

contact with moving chain.

REPLACING SAW CHAIN

WARNING: Cutting edges on

chain are sharp. Use protective

gloves when handling chain.

IMPORTANT: Do not clamp chain-

saw in vise to replace saw chain or

guide bar.

Replace chain when cutters are too worn

to sharpen or when chain breaks. Only use

replacement chain noted in this manual.

Always include new drive sprocket when

replacing chain. This will maintain proper

driving of chain. Note: For proper chain and

drive sprocket, see Parts List.

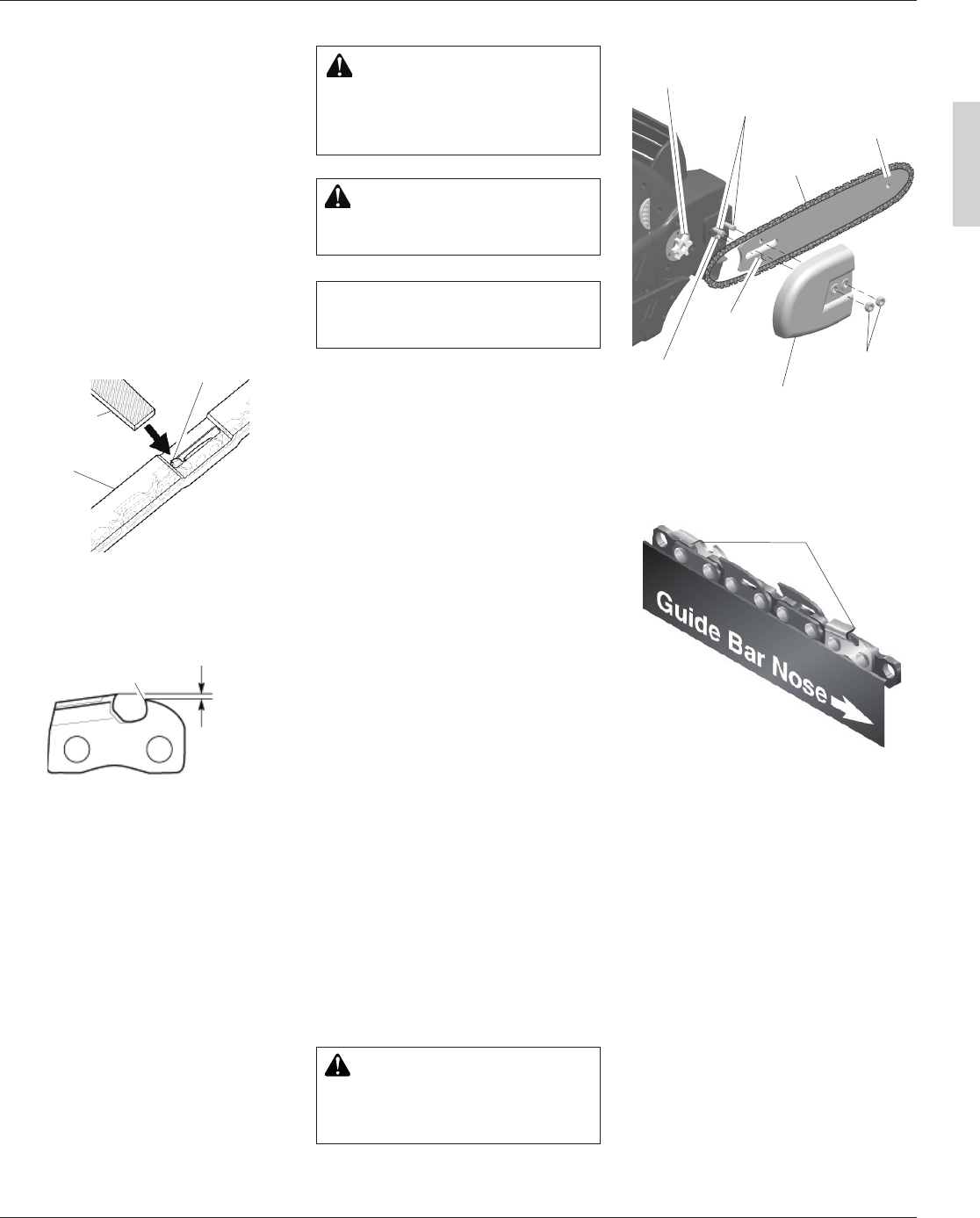

Refer to Figure 36 while completing the

following steps.

1. Loosen and remove guide bar nuts.

2. Remove sprocket cover.

3. Remove saw chain.

4. Place new chain around drive sprocket,

along top groove of guide bar, and around

guide bar nose. Note: Make sure cutting

edges of chain are facing in right direction.

Position chain so cutting edges on top of

guide bar face guide bar nose (see Figure

37 and indicator on side cover of saw).

5. Before placing sprocket cover onto guide

bar bolts, verify that the adjusting nib is

in the adjusting hole on the guide bar.

6. Place sprocket cover onto guide bar

bolts.

7. Thread guide bar nuts onto guide bar bolts.

IMPORTANT: Finger tighten only.

8. Adjust chain tension. Follow steps under

Saw Chain Tension, page 12).

9. Securely tighten guide bar nuts with

wrench.

CAUTION: Do not place chain

on saw backwards. If chain is back-

wards, saw will vibrate badly and

will not cut.

GuideBar Bolt

s

Adjusting Nib

Saw Chain

Sprocket

Guide Bar

Sprocket Cover

Guide Bar Nuts

Figure 36- Guide Bar and Saw Chain

Replacement

Figure 37 - Correct Installation of Saw

Chain

Cutting Edges

Adjusting

Hole

Filing Cutter Depth Gauges

The cutter depth gauge clearance is reduced as

cutters are sharpened. After every second or

third sharpening, reset cutter depth gauges.

1. Place depth gauge tool (.025") fi rmly

across top of two cutters. Make sure

depth gauge enters slot in depth gauge

tool (see Figure 34).

2. Use medium fl at fi le. File depth gauge

level with depth gauge tool.

3.

Remove depth gauge tool. With fl at fi le,

round off front corner of cutter depth

gauge (see Figure 35).

After several hand fi lings, have authorized

service center or sharpening service machine

sharpen chain. This will insure even fi ling.