10

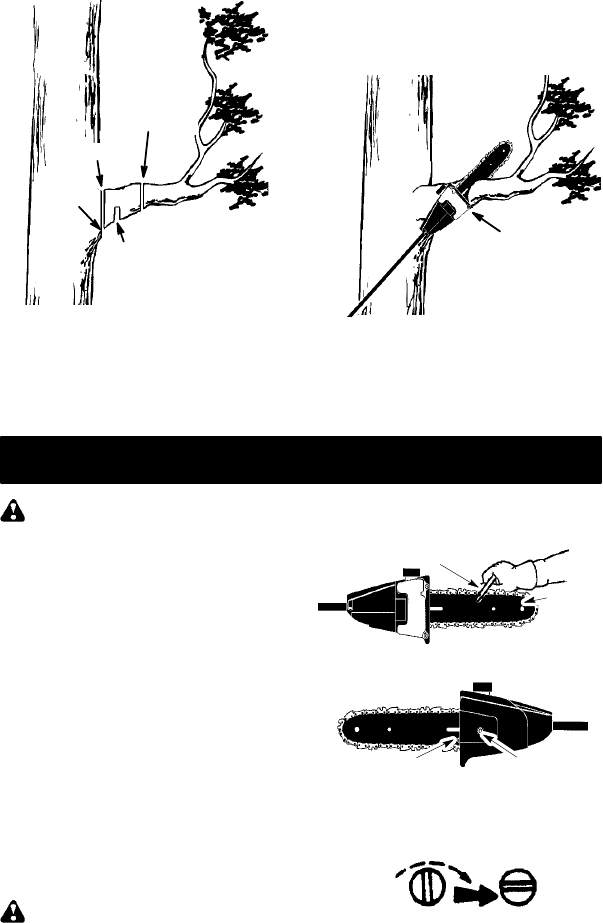

Pruning technique

Second cut

Third cut

Collar

First cut

1. Make the first cut 6 inches from the tree

trunk onthe bottomof thelimb. Use topof

guide bar to make t his cut. Cut 1/3

through the diameter of the limb.

NOTE: When making the second and third

cuts, rest t he foot of the pruner against the

tree limb that is being cut to prevent whipping

of the branch.

Foot

2. Next,move 2-- 4inches fartherout onthe

limb and make a second cut all the way

through the limb.

3. Then,makea finalcut leaving a1 -- 2inch

collar from the trunk of the tree to avoid

damage to the tree.

MAINTENANCE

WARNING: Always stopunitanddis-

connect spark plug wire (or disconnect unit

from power source) before performing main-

tenance.

CHECK FOR D AMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

S Oil tank -- Discontinue use of pruner attach-

ment if oil tank shows signs of damage or

leaks.

CHECK FOR LOOSE

FA STENERS AND PARTS

S Bar clamp nut

S Fasteners

INSPECT AND CLEAN UNIT AND

DECALS

S After each use, inspect complete unit for

loose or damaged parts. Clean the unit and

decals u sing a damp cloth with a mild deter-

gent.

S Wipe off unit with a clean dry cloth.

CHECK CHAIN TENSION

WARNING: W ear protective gloves

when handling chain. The chain is sharp and

can cut youevenwhen itis notmoving. Make

chain adjustments with lower end supported.

Chain tension is very important. Chains

stretchduringuse. This isespecially truedur-

ingthefirstfew times youuse yourpruner . Al-

ways check chain tension each time you use

and refuel your unit.

1. Use a screwdriver to move chain around

guidebartoensurekinks d onot exist.The

chain should rotate freely.

Chain Adjustment Tool

Guide

Bar

2. Loosen bar clamp nut until it is finger tight

against the bar clamp.

Bar clamp nut

Adjusting Screw

3. Turn adjusting screw clockwise until

chain solidly contacts bottomof guide bar

rail. Then, turn adjusting screw an addi-

tional 1/4 turn.

Adjusting Screw -- 1/4 Turn

4. Using a screwdriver , roll chain around

guide bar to ensure all links are in bar

groove.

5. Lift up tip of guide bar to check for sag.

Release tip of guide bar, then turn adjust-

ing screw 1/4 turnclockwise. Repeat until

sag does not exist.

6. While lifting tip of guide bar, tighten bar

clamp nut securely with a wrench.