19

hand until lock engages hole in motor

spindle.

3. While holding spindle lock

engaged, tighten collet nut securely by

turning clockwise using wrench

provided.

NEVER TIGHTEN COLLET

WITHOUT BIT INSERTED, TO DO SO

MAY CAUSE DAMAGE TO COLLET.

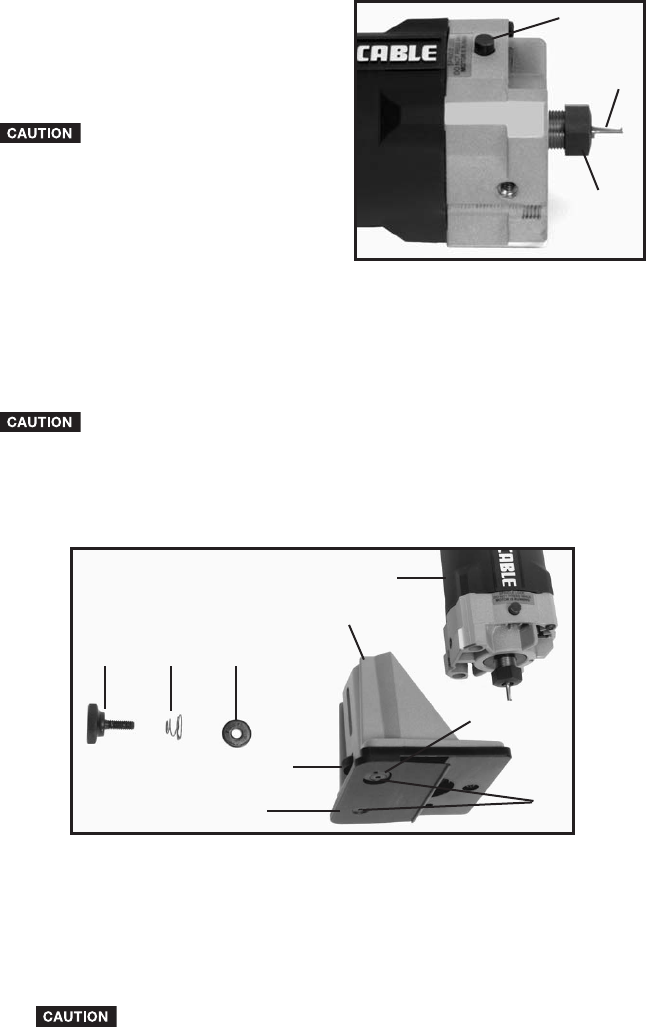

4. Position base (A) Fig. 15, to motor

(B) and secure using locking screw (E),

spring (D) and washer (C).

NOTE: Orient spring with small end

against head of locking screw.

5. Align the two holes in the undersciribe attachment (G) Fig. 15, with the

two holes in the base (A).

6. Attach the underscribe attachment (G) Fig. 15, to the base (A) with two

screws (H) and eccentric washer (J).

ADJUSTING BIT EXPOSURE

DISCONNECT TOOL FROM POWER SOURCE.

1. Loosen base locking screw (E) Fig. 15, approximately one-quarter of a

turn.

2. Turn depth adjusting wheel (F) Fig. 15, counterclockwise (looking at top

of wheel) to lower bit until it just touches the guide plate.

3. Firmly tighten locking screw (E).

ADJUSTING GUIDE PLATE

The Underscribe Trimmer Base is equipped with an adjustable guide plate

(see Fig. 16). The guide plate is adjusted by rotating the eccentric, using a

special wrench that is supplied with the Trimmer Base. To adjust guide,

proceed as follows:

1. Make a trial cut using scrap material and check fit.

2. DISCONNECT TOOL FROM POWER SOURCE.

3. Turn eccentric to correct fit-up:

If joint is TOO LOOSE (crack between the two pieces of laminate), turn

eccentric clockwise.

If joint to TOO TIGHT (laminate will not snap into place), turn eccentric

counterclockwise.

Fig. 14

A

B

C

Fig. 15

A

B

CDE

F

G

H

J