13

ASSEMBLING AND ADJUSTING BASE AND GUIDE

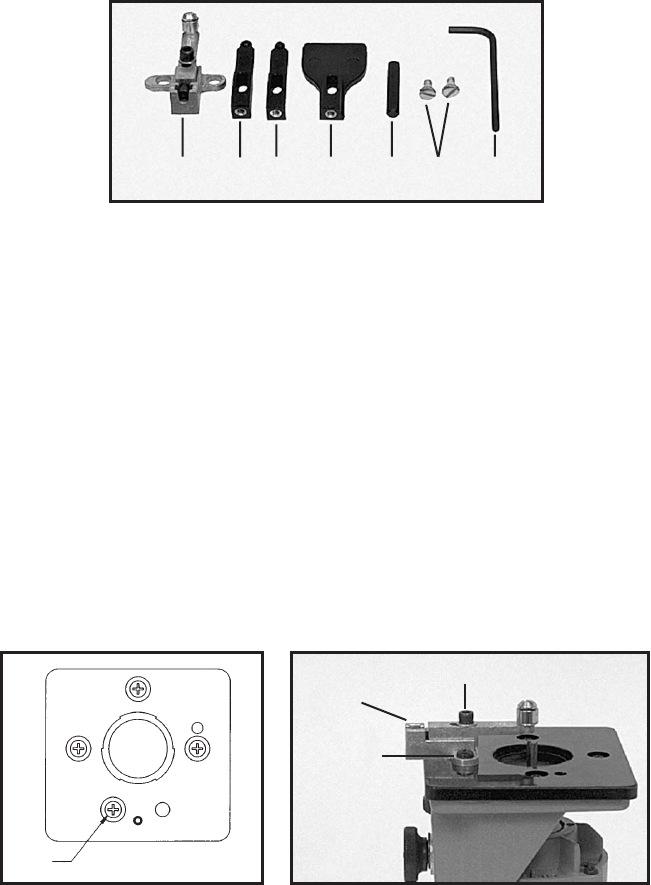

1. The base and roller guide (A) Fig. 4, are assembled at the factory. To

assemble to trimmer: Remove one sub-base mounting screw (A) Fig. 5, insert

alignment pin in guide base into hole in bottom of trimmer sub-base and fasten

with two mounting screws (F) Fig. 4, as shown in Fig. 5A. Do not tighten at this

time.

2. Install 44858PC bit to trimmer as outlined under TO INSTALL BIT.

3. Align roller guide with bit by loosening locking screw (Fig. 5A) and

turning adjusting screw, with wrench provided, until guide is in desired

location.

NOTE: Guide mounting holes are oversized allowing guide to be

rotated on alignment pin to align guide roller with bit.

4. Tighten all screws and make a trial cut on scrap material to check

alignment. Readjust if necessary.

5. For making flush cuts align roller guide with straight portion of bit.

6. For bevel cuts adjust cutting depth so that only the bevel portion of bit

projects through trimmer base and adjust roller guide to produce desired

amount of bevel.

FLUSH TRIMMING WITH PILOTLESS BIT WITH

3

/8" LENGTH FLUTE

1. Attach base and guide to trimmer as outlined under ASSEMBLING AND

ADJUSTING BASE AND GUIDE.

2. Remove roller guide and replace with flush trimming guide (B) (Fig. 4).

This guide may be identified by the molded on letter “F”. Stud on end of

guide must face towards trimmer base.

3. Install guide setting gauge (E) (Fig. 4) to trimmer so that hole in end of

gauge may be positioned over stud in guide.

Fig. 4

ABCD EFG

ADJUSTING

SCREW

LOCKING SCREW

MOUNTING

SCREW

Fig. 5A

Fig. 5

A