14

4. Adjust guide until hole in gauge fits over stud on end of gauge. Tighten

all screws securely.

5. Remove guide setting gauge from trimmer and install the bit as outlined

under TO INSTALL BIT.

NOTE: It will be necessary to separate motor from base to remove

setting gauge and install bit.

6. Adjust depth of cut so that the straight portion of bit extends below

trimmer base at least equal to the thickness of material to be trimmed.

7. Make a trial cut on scrap material to check alignment. Readjust if

necessary.

BEVEL TRIMMING WITH PILOTLESS BIT WITH

3

/8

" LENGTH FLUTE

1. Follow steps 1 thru 5 under the previous section, except install bevel

trimming guide (C) (Fig.4). This guide may be identified by the Letter “B”

molded on.

2. Adjust depth of cut so that only the bevel portion of the bit extends

below trimmer base at least equal to the thickness of material to be trimmed.

3. Make a trial cut on scrap material to check alignment. Readjust if

necessary.

USING STRAIGHT EDGE GUIDE

The Straight Edge Guide (D) (Fig. 4) may be used with either 44858PC or a

pilotless bit with

3

/8" length flute for trimming long straight edges.

Assemble to guide base and adjust similar to other guides.

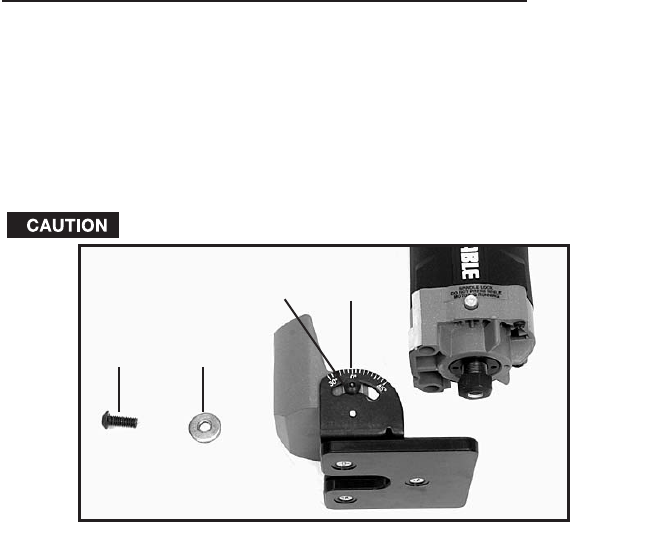

MODEL 7319 TILT BASE TRIMMER ASSEMBLY

Model 7319 Tilt Base Trimmer is completely assembled at the factory. The

base is assembled or removed from Model 7301 motor with base locking

screw (A) Fig. 6.

NOTE: There is a flat washer (B) Fig. 6, on the locking screw.

Model 7319 Tilt Base is designed for use with 43216PC flush trim bit

for trimming into corners. It may also be used with other “self pilot”

trim bits for conventional trimming at 90° setting.

ADJUSTING DEPTH OF CUT

DISCONNECT TOOL FROM POWER SOURCE.

Fig. 6

C

D

B

A