GB - 22

Slow charge:

• 10 hours @ 5 amps

• 3 hours @ 10 amps

Fast charge:

• 2-1/2 hours @ 20 amps

• 1-1/2 hours @ 30 amps

• 1 hour @ 45 amps

5. If when charging the battery, violent

gassing or spewing of electrolyte occurs,

or the battery case feels hot (125°F -

52C), reduce or temporarily halt

charging to avoid damaging battery.

6. Always turn charger to “off” before

removing a charger lead from the

battery.

JUMPER CABLES

The battery on the 8400 is located at the rear

of the tractor (see Figure 14).

1. Stop the engine on the vehicle with the

good battery.

2. Connect one jumper cable to the

positive terminal on the good battery.

Connect the other end of the jumper

cable to either the positive terminal on

the dead battery or the battery side of

the solenoid located on the right front of

the engine.

3. Connect one jumper cable to negative

terminal on dead battery. Connect the

other end to ground (frame) of vehicle

with the good battery.

BELTS

For efficient performance of your machine,

worn or frayed belts must be replaced. Check

belt tensions as instructed (see SERVICE

AND ADJUSTMENTS on page 16).

ENGINE FUEL FILTER

Before servicing the fuel filter, thoroughly

clean outside of filter housing and fuel hoses.

Dirt must not be allowed to enter into fuel or

fuel system. Refer to manufacturer’s Engine

Manual for instructions.

ENGINE

Refer to manufacturer’s Engine Manual for

maintenance schedule recommendations.

Change oil and oil filter after the first 5 to 8

hours of operation.

ELECTRICAL SYSTEM

Make certain all terminals and connections

are kept clean and properly secured.

1. Check switches regularly to be sure they

are kept clean and operating correctly.

2. Keep wire harness and all individual

wires away from moving parts, hot parts,

or sharp edges. This will prevent

abrasive wear or potential short circuits.

3. Exercise extreme care when working

with electrical system.

HYDRAULIC HOSES

Hydraulic hose and tube lines should be

inspected every week to check for cuts, loose

connections, kinks, and wear.

Be sure tubes and hoses do not come in

contact with other frame parts which could

cause abrasive wear. Always replace worn

hoses or tubes before operating machine.

1. Assemble nut, sleeves and tube to fitting

body with minimum torque (finger tight)

until flare contacts seat on fitting body.

2. For tightening reference, mark a line

lengthwise on both the nut and adapter

fitting with a marker.

3. Using a wrench, rotate the nut to tighten.

Turn the nut to the amount shown in the

chart below. The line will show which

fitting has been tightened and how

much.

4. On hoses with “o-ring” fittings, make

sure o-rings are clean and hose fittings

are properly seated by hand before

wrench tightening.

5. Hold the fixed portion of the hose

coupling with one wrench; use a second

wrench to tighten or loosen the hose nut.

This will prevent damage to the fitting

seal. When tightening a hose, do not

allow it to twist; hold it in a normal,

straight position.

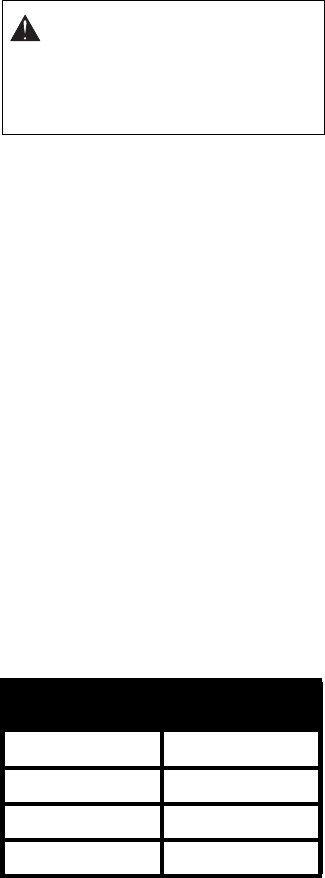

DANGER: To avoid serious bodily

injury, always lower mowers to the

ground, place all controls in neutral

and shut off engine before

inspecting hydraulic lines or hoses.

Never run hands across tubes,

hoses or fittings to check for leaks.

Tube O.D. or

Hose

Rotate # of Flats

3/8" 2

1/2" 2

5/8" 1-1/2-2

1" 3/4-1