GB - 13

TRACTOR

1. Remove crating top, front, and sides.

2. Cut banding from around tractor, tires,

and armrest box.

3. Separate steering wheel from tire.

4. Remove rear mower belt shield from

manual lift handle.

Lift tractor up off axle crate supports to

sufficiently assemble tire and wheels to the

tractor.

Lower tractor down onto crate. Tractor may

now be driven or rolled off the crate. To allow

the tractor to roll freely without engaging the

engine or drive, a tow valve is provided. It is

located under the hood directly behind the

engine (see Figure 3).

REAR MOWER

1. Remove rear mower from crate and

position behind tractor as shown in

Figure 5.

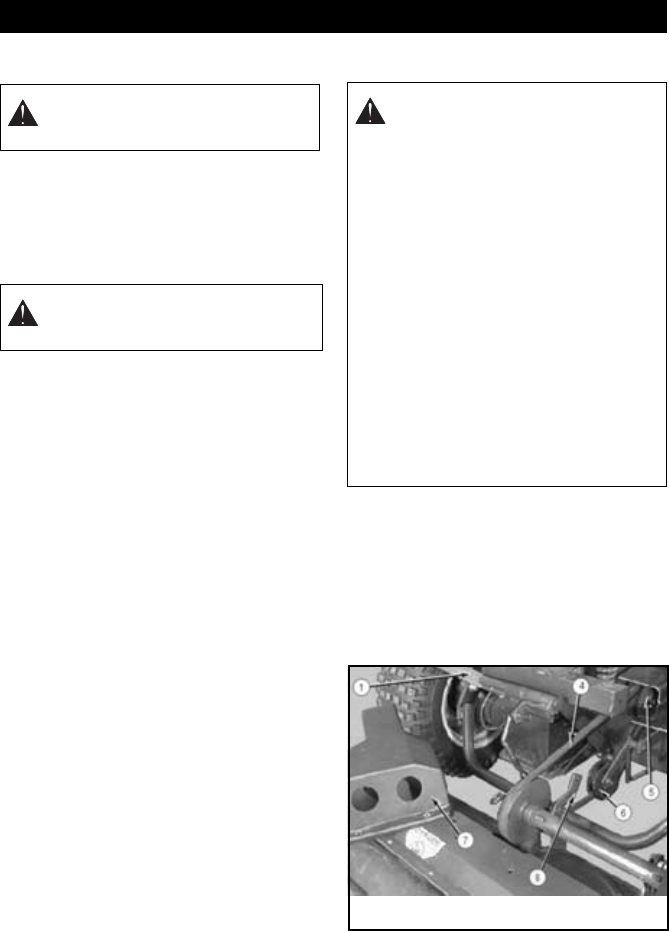

2. Pivot rear mower lifter handle (1,

Figure 5) up and back to lower rear

mower pull plate on the pull yoke.

Position mounting flange (2, Figure 6)

on the center front of the rear mower

frame under the pull plate (3, Figure 6)

and fasten securely with two fasteners

already installed in pull plate.

3. Install V-belt (4, Figure 5) onto double

groove pulley (5, Figure 5) located on

the right rear side of the frame. Raise

rear mower belt idler (6, Figure 5), and

run V-belt under idler pulley as shown.

4. Position rear mower clutch guard (7,

Figure 5) over rear mower shaft and

pulley area, and fasten right side to

support (8, Figure 5) with a 1/4”–20 x

1/2” round-head slotted screw. Secure

rear flange of guard with (2) 1/4”–-20 x

1/2” hex head cap screws, lock washers,

and nuts.

Check Tire Pressure

SEAT

1. Fasten seat /slide assembly studs (1,

Figure 7) into slotted holes in hinge

mounting plate (2, Figure 7) four places

and fasten with four 5/16” flat washers

and nuts.

2. Remove armrests (3, Figure 8) from box

strap to the crate. Attach to seat with

fasteners provided.

ASSEMBLY

CAUTION: Handle banding

material with caution. Use heavy

leather gloves. Banding is sharp!

CAUTION: Use jack stands under

tractor whenever elevated off the

tires.

CAUTION: Avoid injury! Explosive

separation of tire and rim parts is

possible when they are serviced

incorrectly:

• Do not attempt to mount a

tire without the proper

equipment and experience to

perform the job.

• Do not inflate the tires above

the recommended pressure.

• Do not weld or heat a wheel

and tire assembly. Heat can

cause an increase in air

pressure resulting in an

explosion. Welding can

structurally weaken or

deform the wheel.

• Do not stand in front or over

the tire assembly when

inflating. Use a clip-on chuck

and extension hose long

enough to allow you to stand

to one side.

Figure 5