MQ PS4030 SAW • OPERATION MANUAL — REV. #0 (02/29/08) — PAGE 49

MQ PS4030 SAW — MAINTENANCE

NOTE

If the Inner Flange does not readily

break free from the tapered Blade

Shaft while the center puller bolt is

tightened, lightly tap on the center

puller bolt to allow the flange to

break free from the shaft.

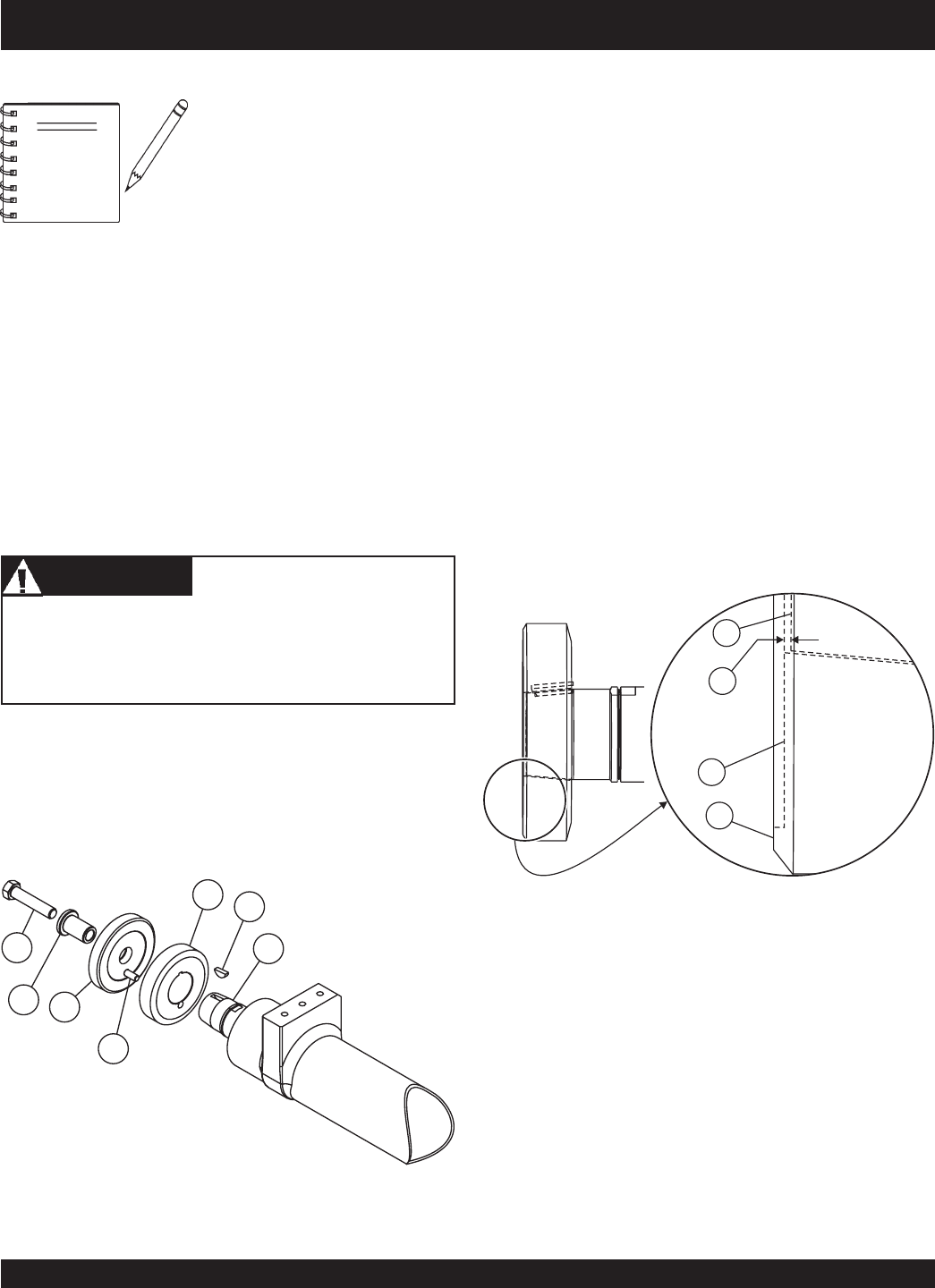

Installing the Inner Blade Flange

1. Ensure that the tapered portion of the Blade Shaft and the

Inner Blade Flange are clean and free of burrs or

indentations. Clean and repair as necessary.

2. Ensure the Drive Key is in place.

3. Slide the Inner Flange onto the tapered portion of the Blade

Shaft.

Figure 56. Inner Blade Flange Installation

DO NOT use lubricant of any kind. Lubricant prevents the

tapered surface of the Flange and Shaft from mating

properly.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

4. Install the Outer Blade Flange, Flange Bushing, and

Mounting Bolt.

5. Tighten with a 1/2" impact wrench to seat the tapered

surfaces of the Inner Flange and Blade Shaft.

1. Mounting Bolt

2. Flange Bushing

3. Outer Flange

4. Dowel Pin

5. Inner Flange

6. Drive Key

7. Blade Shaft

1

2

3

5

6

7

4

6. Loosen the Mounting Bolt and remove the Outer Flange

and Bushing.

7. Inspect the Inner Flange to ensure the proper seating of

the tapered fit. The Inner Flange should be seated between

.030" and 0.0" (flush) to the end of the Blade Shaft. (See

Figure 57)

1. Blade Shaft

2. Tolerance

3. Inner Flange Inside Face

4. Surface Area to be Checked

For Runout While Rotating

Figure 57. Inner Flange Seating

8. Test to ensure that the Inner Flange does not wobble when

rotated. Use a dial indicator on the face of the Flange. (Item

4 Figure 57.) Maximum tolerance is .002" runout on the

face of the Flange when rotated.

1

3

2

4

0.000”

to 0.030”